Meet Nikita Taylor, David Beriault, and Aaron Culver – referred to as NT, DB, and AC from here on out – the three Canuks that make up Red Point Climbing Holds. The company formed from the imagination of a 16-year-old Nikita (whom we met in Squamish almost 2 years ago) and has grown into a full-fledged passion project, spreading grippy holds across the world. Hope you enjoy their story!

Serious bizniss.

How & when & why was Red Point Climbing Holds formed? What did you think was missing from the climbing holds market?

NT: I started Red Point in 2012 when I built my little home wall. I began making some grips in my garage for fun and joined forces with Dave Beriault, an engineer and climber. At the time we were just experimenting. The possibilities were limitless and we didn’t know what we were looking for. We didn’t expect to grow to what we are now but after meeting Aaron Culver, who is our phenomenal in-house head shaper, we got a lot more serious. In the beginning, we were more interested in just making cool holds but we have reached a point now where we can look to push the envelope.

Related to the above — What makes you different from other climbing hold companies?

Team Response: The market is fairly saturated with a large number of companies. It seems everybody is nearly on par in terms of material, warranty and quality so it really comes down to design and shapes. At this point we are trying to raise the bar by developing new shapes people haven’t thought of, and bring out new technologies and designs that refine and evolve what a climbing hold is. We don’t want to spoil anything, but some mega-klasic things are in the woodworks right now.

Who does what? Basically, how are duties spread out between the three of you.

AC: Head shaper. I have the best gig. It’s by far the most fun.

NT: I am responsible for production, shipping and customer relations. I work with the urethane and get orders out the door. Shortly we anticipate some changes in our production flow and things will be switching up.

DB: In the beginning phases of the company I provided the funding needed for supplies and worked with Nikita to hone the brand and our logo.I did a lot of work with Nikita in the refining our processes and aiding in the development of our product offering.These days the company is self funded and I have been focusing on building molds, hollow backs, and refining our business model.

Where is the company located?

NT: In Kelowna, British Columbia, the heart of the sunny Okanagan Valley. Look for the sunglasses for scale in our product photos and now you know why.

Walk us through a typical day in the office (if there is one).

NT: There is nothing typical about a day with Red Point. Some things you might read in the job description are dealing with 600 pound barrels of un-cured polyurethane component, printing more shipping labels than you would/could ever read, removing fresh holds literally ‘hot’ off the press (the plastic emits heat when setting) and handling enough new grips to satisfy any route-setter’s hold fetish.

Getting creative.

What the heck is the process of shaping and pouring holds?!

AC: I’m constantly collecting shape and texture ideas. Pretty much from anywhere. Then I try to transfer that idea to foam. Sometimes it works, often it doesn’t. Sometimes it takes several attempts before I’m satisfied with it. As far as making a set or series, we talk about know what types of holds we want to be making and approximately how many. Then I work on a style or texture that I feel meets the need. Actually carving out the shapes doesn’t usually take a lot of time, although not every hold I shape makes it into the final set. It’s the sanding and finishing work that takes the time. Usually if I think I’m just about done and I put a piece down for a bit, when I pick it back up I can see more flaws to fix. It can be frustrating at times. Sometimes I will complete a set only to see that one or two pieces don’t really match what I’m going for and I need to make more. It’s a long process but totally worth it.

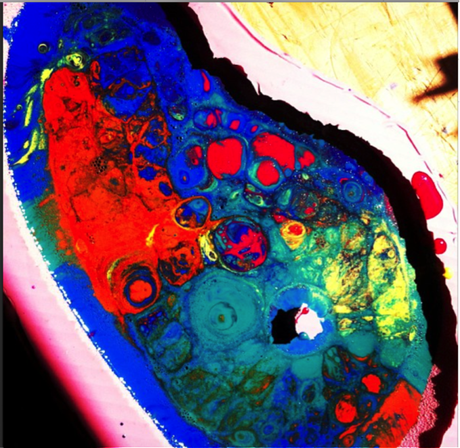

NT: After the holds are shaped by Aaron, they will go to David Beriault where he works some magic with silicone and mold boxes and out pops a reusable negative of the shape. After I receive the mold I clean out the old foam used to prototype the hold and get it ready for production. At this point I mix up a batch of urethane from a two part system. Carefully, the plastic is poured into the molds where it sets and transforms from a translucent liquid into a rigid opaque solid. This step is pretty neat to watch. After its fully cured, I pop out the new grip, the backs are levelled off on a belt sander, then checked for quality control and dusted off. I’ll then bag them up and off they go to the home woodie, gym or what-have-you.

Plastic mid-way through setting.

How do you decide on a new hold shape? What are your favorite shapes?

NT: We look at what is going to be new and beneficial for the market. We want to bring something creative and epic that makes a positive impact and fills out our product offering. You are going to see a revamp happening to our line-up shortly so I don’t want to answer what my favorite shapes are yet but currently they would have to be our Sliver Jugs. They are über friendly and good value for the price.

What is your most popular hold shape?

DB: The Brimstone set seems to have been well received. We have some plans in regards to these textures.

What material do you use to make holds? Where do you source the material?

NT: We use a semi-rigid polyurethane that holds up well to heavy gym traffic. We get it from a urethane supplier if that helps?

Drums of urethane.

Do other companies use different material? If yes, why did you choose what you use?

DB: Short answer; yes they do. There are many different manufacturer and suppliers of plastics. Some companies skimp on quality and may use a resin or lower quality urethane. There are a plethora of reasons they may do this but in the end, they are lead to an inferior hold. The main reason we use our urethane is that’s it’s a high-quality product that consistently meets our needs and is cost effective.

What have been your company’s biggest setbacks or hurdles to overcome?

NT: I am a full time engineering student so finding time between school and Red Point has been a challenge to say the least. To start a quality grip company, you need dive right in and provide all the funding it needs. I can’t overstate how challenging it is to build a product line with limited financial backing.

DB: I am an engineer as well so between working a full time job, starting Red Point and trying to climb has been tricky. There were times I wanted to throw in the towel as we considered ending Red Point but our drive to be purveyors of quality products has kept us in the game.

Describe your best day since starting the company.

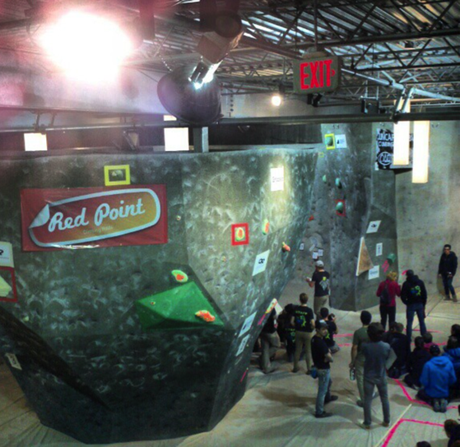

NT & DB: When we got to sponsor a Tour de Bloc (Canada’s biggest competition series). A women’s final problem was set entirely with Red Point grips at The Hive Bouldering Gym and it was epic to see everybody stoked on our grips. Our banner was front and centre, there was a buzz about our grips and at that point, we felt we had arrived on the scene.

Red Point holds at the Hive Tour de Bloc competition.

What does the future hold for Red Point? Will the company continue to focus solely on holds?

Team Response: We will do other schwag but our focus will remain on quality grips and new products. We are looking forward to building new gym-friendly sets, website restructuring for ease of ordering, and a revamp of our product offering. Our final goal is to improve the customer’s experience while ordering and crushing on our grips.

Do you ship to the US? What gyms (in Canada and beyond) currently use your holds?

NT: We sure do ship to the US. More detail would be unnecessary. I literally cannot list all the gyms, but some major hitters are Boulderz in Toronto, the Hive in Vancouver, and Tosho Corporation (a wall building company) in Japan. We’ve shipped all over the world including Asia, Australia, the Caribbean, you name it and they’re probably there. Recently we sponsored Canada’s first route-setting competition with some of our newest shapes and helped out on a number of other events.

How long do your holds hold up?

DB: The plastic is pretty well indestructible compared to older resin holds, however texture is expected to wear smooth after a length of time. This would depend on how much traffic the grips receive, in particular footholds. To address this challenge, we found a harder urethane that holds up better to wear. We have a 3 year warranty that covers manufacturing defects and we consider on a case by case basis any other failures. Basically, if you have an issue, get in touch with us and we will do our best to mediate it.

Any other tidbits that climbers should know about hold manufacturing that we have no clue about?

Team Response: Look peeps; making holds out of real rock is nothing new before you suggest that. But on a more serious note, there are so many trials and tribulations that go on behind the scenes before streamlining the process and product. Making grips is time consuming and if you aren’t going full-on, it’s tricky to get off the ground. If you are interested in making your own holds, all we can say is that it’s oodles of fun and a shit-ton of challenges, but with a bit of luck and boatload ingenuity you can start pumping out some quality grips.

NT: Another thing I would like to point out is that we don’t make climbing holds to make money. We do it because we love to climb. We breathe, eat, love and live climbing. Even though there are times in life where distractions and responsibilities pull us back, every night before our heads hit the pillow, that sick new problem or ground-breaking idea for a pinch is running through our heads again and again. Red Point is for me, as well as Dave and Aaron, an outlet to give back to a community that has given back so much. It’s a way we can promote climbing by getting people syked on grabbing little blobs of plastic in their hands. We want you to grunt, yell, swear, cry, think, power-scream and have a good time too. That’s what Red Point is about to us.