Sequestration?

Near the end of my recent post about a geo-hike down Jesse Ewing Canyon in the eastern Uinta Mountains, I mentioned a pipeline. There was no way to miss it—it was clearly and emphatically marked.

Pipeline route down Jesse Ewing Canyon into Browns Park. Uinta Mountains continue in the distance.

Why is CO2 sent down Jesse Ewing Canyon, across Browns Park, over the Green River and up into the Uinta Mountains? In fact, why is carbon dioxide being transported at all?

CO2 crosses the Green in a pipeline suspended above the river.

Arrow marks pipeline route above Browns Park, after crossing the Green River.

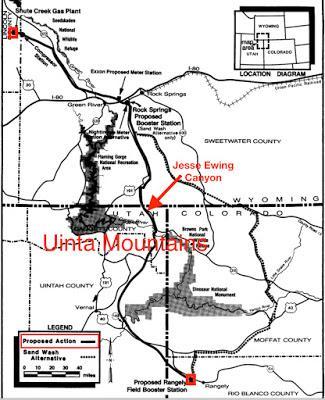

My first thought was sequestration. Oil and gas extraction produces climate-warming CO2, and the industry is under pressure not to release it into the atmosphere. In Wyoming, we talk a lot about carbon capture and sequestration (CCS) … could this CO2 be going somewhere in the Uintas to be injected into suitable rock layers deep underground? Of course that would require Federal funding—sequestration is expensive!Or could it be that this CO2 is being somehow put to use? That’s what I asked a candidate for the Wyoming state senate, a passionate advocate for research on economically-viable uses of CO2. But like me, he was puzzled and guessed Federally-subsidized sequestration. But we were wrong. The CO2 is being put to use, specifically for enhanced oil recovery (EOR). It's sent to an aging oil field to extract a bit more oil.The CO2 originates at the LaBarge natural gas field in southwest Wyoming. After being captured and processed, it travels southeast to Rock Springs, then south through Clay Basin to the head of Jesse Ewing Canyon in Utah. Next it descends to Browns Park, crosses the Green River, climbs a bit higher into the Uintas, descends, crosses the Green River again, and finally arrives at Rangely, Colorado, after a trip of 177 miles.

Bold line is the Rangely pipeline route (BLM 1984).

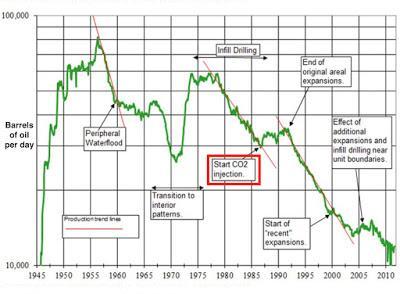

At Rangely, CO2 is injected 6000+ feet underground into the Weber Sandstone. The Weber was once dunes and river sand, back during the time of the Ancestral Rocky Mountains 245-315 million years ago. Several hundred million years later, after the sand had turned to rock, the Laramide Orogeny (uplift of the modern Rocky Mountains) folded the rocks to produce the Rangely Anticline—an elongate dome with multiple layers of trapped oil.The Rangely field is one of the largest in the US, “with cumulative production of about 900 million barrels of oil and 700 billion cubic feet of natural gas” (as of 2014; source). Serious production began in 1933 and peaked around 1955. Since then, secondary (water) and tertiary (CO2) enhanced oil recovery have been used to coax more oil out of the ground.CO2 enhanced oil recovery started at Rangely in 1986. It didn’t reverse production trends longterm—the Rangely is mature and most of the oil is gone. But there was a shortterm increase, enough to justify expenditures.

Originally from Chevron; found on multiple websites (see Sources).

Earlier, I hinted that extra financial incentives drive carbon sequestration … is that true for enhanced oil recovery as well? Is it really profitable to buy processed CO2 and ship it 177 miles? The Shute Creek (LaBarge) processing plant alone cost $70 million to build, and as of 2005, required $1 million per month to operate (CO School of Mines 2005). Not surprisingly, EOR is a balancing act strongly influenced by market forces.“Enhanced oil recovery processes reverse the trend toward lower oil cuts for a short term, but even these processes become victims of dropping oil cuts. When this happens in a tertiary CO2 miscible project, the added burden of CO2 purchase and recycle costs makes competing with lower cost oil difficult. This increases the risk for early abandonment of once proved EOR reserves and a lower financial yield on the sizable EOR investments.” (Masoner and Wackowski 1994)As of late 2015, CO2 was still traveling the 177 miles from LaBarge to Rangely (Smith 2016), suggesting EOR was still profitable.

Because so much CO2 has been injected into the Weber Sandstone (26 million tons as of 2010), Rangely is being counted as a carbon capture and sequestration project (IEA 2010). So the senate candidate and I were partially right in guessing sequestration … or were we? Maybe not. Enhanced oil recovery may well generate more CO2 than it sequesters! See Thomas W. Overton’s recent discussion in Power Magazine (April 2016):

“From where I’m sitting, if the point of CCUS is to reduce CO2 emissions, EOR is about the last thing it should be used for. On the other hand, if the point is to redistribute vast amounts of money, it’s off to an excellent start.”

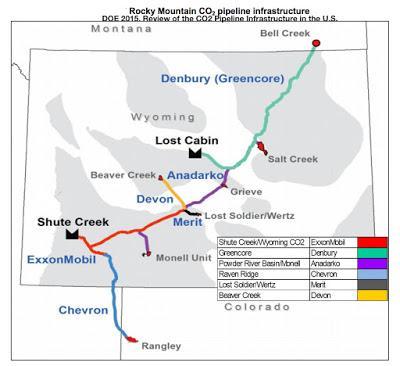

Our CO2 pipelines (Wallace et al. 2015).

SourcesBiello, D. 2009. Enhanced oil recovery: how to make money from carbon capture and storage today. Scientific American (online). https://www.scientificamerican.com/article/enhanced-oil-recovery/#

Bureau of Land Management. 1984. Rangely carbon dioxide pipeline; public scoping document. https://ia601602.us.archive.org/4/items/rangelycarbondio05unit/rangelycarbondio05unit.pdf

Colorado School of Mines. 2005. ChevronTexaco’s Rangely oil field operations. http://emfi.mines.edu/emfi2005/ChevronTexaco.pdf

Cramer, R. 2014. Vertical conformance, the challenge at Rangely. http://www.co2conference.net/wp-content/uploads/2014/12/9-Cramer-Chevron-Conformance_Improvement_The_Challenge_at_Rangely_12-11-14.pdf

Gibson, R. 2014 (July 8). Rangely oil & gas field. History of the Earth (blog). http://historyoftheearthcalendar.blogspot.com/2014/07/july-8-rangely-oil-gas-field.html

International Energy Commission. 2010. Report to the Muskoka 2010 G8 Summit: carbon capture and storage; progress and next steps. http://www.ccsassociation.org/docs/2010/IEA%20&%20CSLF%20Report%20to%20Muskoka%20G8%20Summit.pdf

Masoner, LO, and Wackowski, RK. 1994. Rangely Weber sand unit CO2 project update: decisions and issues facing a maturing EOR project. Society for Petroleum Engineers. http://dx.doi.org/10.2118/27756-MS

Overton, T. 2016. Is EOR a dead end for carbon capture and storage? Power Magazine (online). http://www.powermag.com/is-eor-a-dead-end-for-carbon-capture/

Reitenbach, G. 2016. When technology tails wag power dogs. Power Magazine (online). http://www.powermag.com/technology-tails-wag-power-dogs/

Smith, T. 2016. Teamwork at Rangely. Geoexpro 12:74-77. http://www.geoexpro.com/articles/2016/01/teamwork-at-rangely

Wallace, M. et al. 2015. A review of the CO2 pipeline infrastructure in the US. US DOE. http://energy.gov/sites/prod/files/2015/04/f22/QER%20Analysis%20-%20A%20Review%20of%20the%20CO2%20Pipeline%20Infrastructure%20in%20the%20U.S_0.pdf