I can say with absolute certainty that this is probably going to be one of my longest blog posts ever! You might want to get comfortable for this one!

Last weekend...

All this talk of weight savings lately has gotten me pretty excited about the latest and greatest changes to Axiom. I got the urge to re-wire Axiom with smaller gauge wire in certain areas on the car where larger gauge wire is unnecessary. I changed out quite a number of wires that were over sized to smaller wires. From weighing out various wires I added and took off the car I'm pretty confident all this resulted in a net weight loss of about 1 lb! To put this into perspective our current weight loss goal is 150lbs.

Along with new smaller wires I also made a new slick driver controls box that I think the drivers of Axiom will really appreciate (see below).

I also re constructed the rear lights to be more durable and lighter (along with smaller gauge wire).

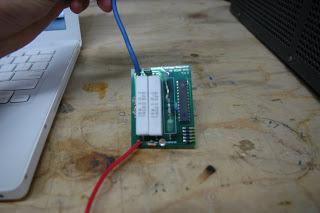

I also finished a design for a digital voltage regulator a while back and some of the electrical team soldered it up and assembled it. We were all pretty keen on getting it running and we were low on parts so we had to improvise. The part mix match you see in the picture below is what resulted.

The regulator attaches to a battery module and will attempt to clamp the voltage of the module to a level that is user programmable. Since its digital it's either on or off and therefore can regulate voltage much more effectively then analog equivalents. I intended it to be used to balance battery packs. You simply put the regulators on, wait for the regulators to do their thing/balance the pack, and then remove them when your done. We tested it out and it works great!

This Weekend...

Today the array guys (George and Denny) built a full solar module. They were testing out a new assembly method we have recently developed and seeing the results today I'm convinced it will put our old array modules to shame. They did have some minor problems but overall it turned out great. Unfortunately we can't show any picture's at the moment as the module was built using our new cells.

Below is Denny and George in the middle of examining the new gen module.

Also you will see in the background a carbon fiber seat (attempt #3 now I think). I have officially deemed this the biggest epic fail I have seen in my time on the UC Solar Team hehe. I hope the mech team can elaborate on this further.

The MPPT crew also got a fantastic start today. They are working on the development of the tracking algorithm for the UC Solar MPPT. So far its been going great but I have a feeling that some hardware changes to the current sensor might be in order (it's acting a bit weird) to get it tracking really nice.

The Electrical Team also assembled one board from the latest revision of our BPS(Battery protection System). It features hot-swappable chips for easy debugging and diagnosing of problems. So far it looks great. I guess we will see how it performs soon.

Today I also had quite an encounter with a stubborn Dewalt battery charger. I wanted to drill a single hole (a single hole!) in something but wouldn't you know it all the batteries in the shop were dead (thanks mech team!) and only one of our two chargers were working. I decided to take apart the busted charger to try to see what was wrong as well as attempt to fix it, chaos then ensued...

Here's me trying to charge up some of the batteries in the shop with one lonely battery charger.

I ended up having to drill out the screws to get it apart as there were tamper proof screws holding the case together. Without too much trouble I managed to drill them out and unscrew the case. Here's what I ended up having to deal with.

I couldn't believe what I was seeing when I opened it up. It looked like it was absolutely soaked at one point and all the parts inside slowly corroded away. This picture is actually after my attempt to fix it up (it looked worse). I replaced a few resistors as well as a transistor, and it seemed to be getting closer to working each time I made a change (more activity on the indicator light).

In the end though I was unsuccessful. I think I will keep it as an ongoing thing to work on if I get bored. If I manage to fix it I will certainly let you know.

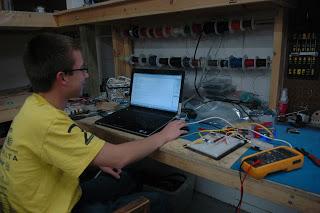

On the other hand here is Jeff working on the new "Superboard" that will take care of all of the tritium driver controls as well as the blinker lights and possibly even telemetry. This should substantially reduce the weight and complexity of the current setup on Axiom. Once this is done we will only have three main pieces of electronics on the car. The BPS, The MPPT's, and of course the Superboard. According to past statistics this project will require one Jeff allnighter plus one Jeff-Tim allnighter. It looks like at the moment the Jeff allnighter of the project is underway...

In a few days time I will make a post about the upcoming race across Australia (upcoming next year) and what our schedule will be like.

Stay tuned!

See Ya!

Tim Gamber

Electrical Engineering Manager