Southeast Asia is an appealing region for boat hauling and refits because of the combination of low costs and skilled workers. The Philippines, Malaysia, and Thailand have shipyards where everything from carpentry to stainless work is available and relatively expensive. Our needs were more modest- just a new bottom, a few through hulls. A combination of timing, opportunity, and economy led us to choose to haul Totem at the Phithak Shipyard and Services in Thailand.

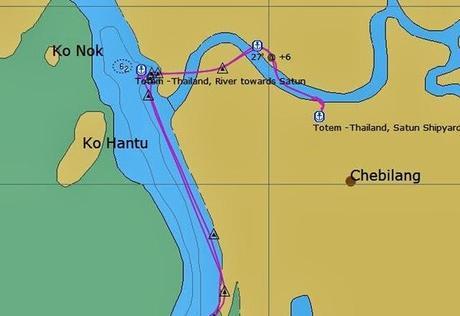

We put time into getting prepared before arrival- the next hurdle for hauling at PSS is just getting there, winding up an inlet of unforgiving shallows with high and rising tide. The charts were sort of helpful.

It’s a strange feeling to be on the roof of your home as it’s positioned on top of an oversized cart, held in place with nothing more than a few enormous clamps around the hull and blocks of wood stuck under the keel. Move that cart jerkily up rails to pull your 20 gross tons out of the water, add a tropical downpour and rapid fire instructions in an unfamiliar language and the whole experience could be a little stressful.

We couldn't understand the directions in Thai, but managers on the side of the slipway gave clear instructions in English for anything we needed to do. Soon Totem was snug in a cradle on the hardstand and ready for work.

We couldn't understand the directions in Thai, but managers on the side of the slipway gave clear instructions in English for anything we needed to do. Soon Totem was snug in a cradle on the hardstand and ready for work.In addition to putting a clean new bottom on Totem, there were four through hulls to replace. Jamie also wanted to take advantage of being hauled out to check our prop shaft and replace the cutlass bearing. We had one week to get it done, and a lot of unknowns.

To help keep us on our deadline to stay on just a week, we hired a couple of the yard staff to speed along the tough job of prep: sanding down the layers of old paint and fairing as needed to give the bottom a smooth surface. It’s hard, dirty work filled with clouds of toxic dust from paint intended to kill marine organisms.

We spent almost five days on prep. The steady rain was only a minor deterrent, as tarps were rigged and sanding continued under cover. It also could have been done faster if we weren’t trying to replace the through hulls, which had to be completed before painting began.

Painting was spread across three days: one coat per day. The first day was spent applying a two-part epoxy primer coat. We thought one pail would be enough: it wasn’t but fortunately, the shipyard had the same paint. Who will ever know the colors don’t match, anyway?

One coat of ablative bottom paint was applied on each of the next two days- nearly three gallons total. We used the dregs for another hit to leading edges and the rudder, where it will wear the hardest.

Jamie started by wearing a protective union suit and gloves that we’d purchased in Langkawi (neither turned out to be available from the store at the shipyard). This provided protection from the toxic antifouling, but was completely unsuitable for the hot climate. When his face became bright red and he sweated so profusely that it literally poured out of the gloves when he lifted his hands, I insisted he get the thing off, sit, hydrate, and then just cut off and wear the sleeve of the suit- the only part of his body that still needed protection.

Totem- with a pretty new bottom- finished and ready to splash! Well, there’s still epoxy paint I still have to cut out of Jamie's hair...

Next: through hulls and other projects