An important challenge for the broader deployment of renewable energy systems, and for making them more reliable and cost-competitive, is overcoming the power generation gaps resulting from the variability of renewable resources. Energy storage technologies and processes such as batteries hold the key for addressing this, and as has been reported in earlier posts on this website are the focus of significant research and development efforts. While it is essential to develop means of energy storage that can be utilized across diverse environments, local conditions can also offer solutions. In some regions where wind energy is rapidly expanding, one possible energy storage option may literally lay right beneath people’s feet.

An important challenge for the broader deployment of renewable energy systems, and for making them more reliable and cost-competitive, is overcoming the power generation gaps resulting from the variability of renewable resources. Energy storage technologies and processes such as batteries hold the key for addressing this, and as has been reported in earlier posts on this website are the focus of significant research and development efforts. While it is essential to develop means of energy storage that can be utilized across diverse environments, local conditions can also offer solutions. In some regions where wind energy is rapidly expanding, one possible energy storage option may literally lay right beneath people’s feet.

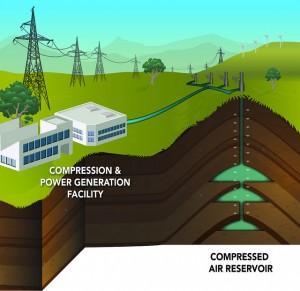

A recent study by the Pacific Northwest National Laboratory (PNNL) and Bonneville Power Administration (BPA) explored the feasibility of storing energy in the form of compressed air energy storage (also referred to as CAES). The concept of CAES is to utilize excess energy–for example, when wind turbines generate more electricity than is needed at a particular time–to generate compressed air, which is then captured and stored underground in suitable geological structures. This compressed air can be returned to the surface and used to generate additional electricity when needed.

CAES is not a new technology or process, and is already in use at two locations: a 290 MW plant in Germany built in 1978, and a 110 MW facility in Alabama commissioned in 1991. These facilities utilize old salt mines to store the captured air. Because there are no similar salt caverns within the BPA’s Pacific Northwest service area, the PNNL/BPA study explored the potential to utilize the porous basalt formations that lie below much of eastern Washington and Oregon for CEAS.

The PNNL/BPA study examined possible locations for CEAS facilities, based on criteria including their proximity to electricity transmission lines and natural gas pipelines, conducive geologic formations, and previously drilled exploration wells to contain storage reservoir properties. PNNL and BPA conducted detailed assessments of two potential sites, for which it designed and analyzed CAES plans. One, the Columbia Hills site in Washington, presented capabilities of 231 MW of load during storage and 207 MW of generation, with estimated storage capacity of 1.5 million metric tons of air. This storage capacity was equivalent to 40 days of continuous CAES injection, and would be capable of 400 hours of subsequent generation without additional injections. The study estimated that this facility would be competitive with most power generating options in the region, with an installed capital cost similar to that of conventional combined-cycle gas turbines at a levelized cost of electricity of as low as 6.4 cents per kWh. (In addition to the image included in this post, another good illustration of how this system works is included in this Seattle Times article.)

A second potential site identified in this study, located near Yakima Canyon in Washington, was examined for a potential no-fuel hybrid geothermal CAES plant, for which the plant design offered 150 MW of load during storage and 83 MW of generation capacity. This site offered the potential for continuous CEAS injection of 1 year, with levelized costs of electricity estimated at 11.8 cents per kWH–competitive with regional renewable energy generation.

These initial findings present some intriguing possibilities, though significant additional research and analysis is needed to examine the technical feasibility, as well as the costs and benefits—economic and environmental—of a project of this nature. CEAS technology may not be viable or cost-effective in many locations in which wind generation is taking place, depending on the local geology and its ability to store compressed air. This technology does, however, demonstrate that solutions to developing viable energy storage technologies and processes may be far more diverse, locally-based, and less far-fetched, than many people recognize.

Image courtesy of Pacific Northwest National Laboratory