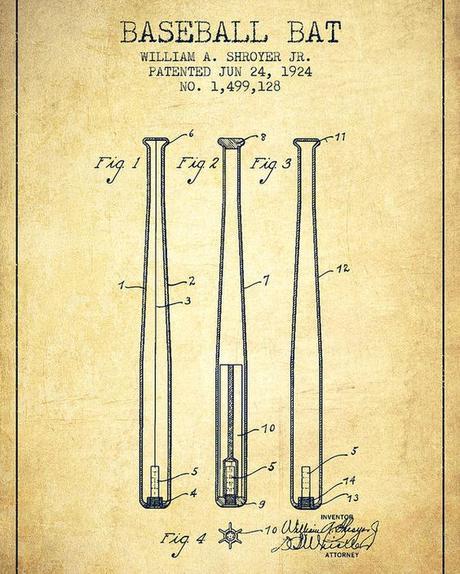

I stumbled across the above image while browsing Pinterest a few nights ago, and it sent me down a rabbit hole looking at the history of aluminum baseball bats. For all the reading I did, I wish I could have found more details about aluminum bat history, but I’ll share here what I did manage to find.

William A. Shroyer patented the first metal baseball bat in 1924 (depicted in the image above), though metal bats were not actually seen in baseball until they started getting produced by Worth Sports Company in 1968 (Worth, Inc. is now a division of Rawlings and Jarden Team Sports). Little League Baseball approved of the use of aluminum bats in 1971, and the NCAA legalized the use of aluminum bats in 1974. By 1975, Worth held the majority of the U.S. aluminum bat market and had produced the first official Little League and NCAA Collegiate aluminum bats.

By today’s standards, however, Worth bats really weren’t that great. According to former Ithaca College baseball head coach George Valesente, “[The Worth bats] made a pinging noise. Grips were not comfortable because they weren’t using the proper leather on the grips. Sometimes, it would start to dent and ding.”

In the late-1970s, Easton introduced a bat made from a stronger grade of aluminum and with rubber grips. Louisville Slugger also soon joined the aluminum bat manufacturing business, and the popularity of aluminum bats skyrocketed, though they were not allowed in major league games. At the collegiate and amateur levels, the switch from wood to metal bats served primarily practical purposes. Because wooden bats were easily breakable, teams would often run dry of bats during games. Aluminum bats essentially eliminated this problem.

In 1993, both Easton and Worth introduced titanium bats, and in 1995 Easton and Louisville Slugger introduced an even lighter grade of aluminum bat. Given the continual improvements of bat technology, it is not hard to understand the popularity of metal bats. Compared to their wooden counterparts, aluminum bats allow for greater bat speed and distance on batted balls, primarily as the result of weight distribution and the ability to make aluminum bats stiffer and lighter. Aluminum bats can even be made to weigh up to 5 ounces less than their length in inches.

Metal bats continue to be banned in Major League Baseball for safety and competitive reasons. For players making the transition from using metal bats in high school or college ball to wooden bats in professional ball, struggles frequently abound. The “sweet spot” on an aluminum bat is much larger and the physics of using a metal bat versus a wooden bat are noticeably different. Players have to relearn their swing and retrain their muscle memory, if they hope to become successful at the big league level. Many purists argue in favor of the classic wooden baseball bat, but one can certainly see that aluminum bats have many appealing qualities for a ballplayer.