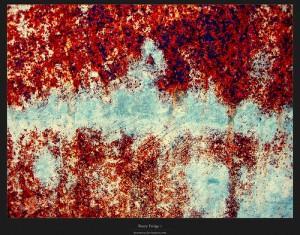

Photo by André Hernâni Meca.

Recently, there have been reports of stainless steel appliances rusting on various news channels. The shocked and understandably upset owners of appliances that started showing rust spots turned to the media when they were unhappy with the response they got from the manufacturers.

In one case, a woman with the coincidental name of Mary Rust found rust stains on her new refrigerator within a year of purchase. Her story made headlines on several news programs.

The news – and many other stories and reviews like it – prompted a lot of questioning about stainless steel appliances, and how it could be possible that appliance made with the metal could rust.

Stainless Steel Is Not ‘Rust-Proof’

Stainless steel is an amazing metal. It is durable, it resists discoloration and even rust. But like all metals – except for pure gold, platinum, or palladium, it will eventually rust. Stainless steel is remarkably resistant, but not immune, to corrosion.

The famous St. Louis Gateway Arch near Goedeker’s showroom, for example, is plated in 304 stainless steel plates. Without any special anti-corrosive treatment, the Arch has remained rust-free for decades.

The remarkable resilience of the metal has led to a common belief that the metal is rust-proof. But it is not. In fact, in scrapyards rust on a questionable metal is one of the ways they can identify a piece of stainless steel because eventually, it will rust.

Usually, though, with proper care a stainless steel surface will remain corrosion free for a long time.

Stainless Steel Is Not A Single Alloy

According to the Stainless Steel Information Center, stainless steel is any iron-based alloy that contains at least 10.5% chromium – the technical name for chrome. There are over 50 types of stainless steel in three different classifications – far more than we can go into here.

Some stainless steel is magnetic, some is not – so the suggestion to use a magnet when shopping for an appliance is not a true test of stainless steel. While nickel is a common metal to be combined with chromium and iron, it is not the only true stainless steel combination.

Just because a magnet does or does not stick to your fridge or oven is not proof that you were ripped off by the manufacturer. The nickel content of stainless steel does not make it rust resilient – nickel is not even a required metal. It can enhance rust resilience.

Stainless steel is corrosion resistant because of the chromium, of which it must contain 10.5%. When chromium comes in contact with the air, it creates a thin layer of chromium oxide – less than the thickness of a human hair at 130 angstroms – that protects the metal from the destructive properties of exposure. If that layer is damages, the protection is compromised.

Environmental Concerns Limit Corrosion Resistance

A recent trend that is impacting the use of stainless steel and its resistance is environmental concerns. This is because the activation or cleaning process uses dangerous chemicals.

One of the last steps in producing finished stainless steel is a process called “passivation” in which the metal is submerged in nitric acid to remove impurities that might compromise the chromium oxide layer.

However, some producers of stainless steel have had to resort to using other cleaning processes that may or may not be as effective. If the chromium oxide layer is compromised by grease, oil, or residue from the factory, it can reduce the effectiveness of the rust resistance.

There Are Different Types of Stainless Steel Rust

“Rust” is a very general term for the oxidation of metal – or in simpler terms, the process of metal and air mixing. While stainless steel’s chromium content helps it resist rust, there are actually several ways oxidation can begin, as explained in this article.

Uniform or General Corrosion With this kind of corrosion, the entire protective surface breaks down. This can be cause by a chemical coming in contact and destroying the film – chlorine, iodine, and bromine are some such chemicals.

Crevice Corrosion This type of corrosion occurs because of exposure to a low PH, or alkaline environment, notably seawater, where the metal is in a crevice or fold where air cannot easily reach the metal. Without oxygen, the chromium cannot re-form the protective layer and rust forms.

Pitting Corrosion This type of corrosion occurs in small spots where the protective layer was removed.

Galvanic Corrosion This is a type of corrosion that has to do with specific environmental factors – mostly seawater and marine – in which electrolytes (salt water) and different metals speed up corrosion. There are specific alloys of stainless steel used for these environments. Therefore the stainless steel fasteners on a boat are probably not the same stainless steel in your kitchen.

Because of each application of the metal, one of dozens of kinds of stainless steel are used. Each has its own strengths and weaknesses, but none of them are completely rust proof.

The Stainless Steel Information Center points out that many times the rust spots seen on stainless steel are rusted bits of other metals, such as iron, that have gotten stuck in the surface. Sometimes these can be cleaned and the protective layer can be restored.

Stainless Steel Requires Particular Care

Stainless steel’s rust resistance, as you saw, is based on a thin layer of protection formed by the chrome and oxygen in the air. If that layer is compromised, the stainless surface will rust.

The Specialty Steel Industry of America has produced a information guide that includes a section on proper care and cleaning of stainless steel. Don’t worry, there is nothing special needed to clean stainless steel, but there are some common household cleaning supplies that can cause rust.

Here are some things you should not do to clean your stainless steel appliances:

Don’t use metal brushes or steel wool. Metal brushes and steel wool are susceptible to rust, and can break through the chromium oxide layer that protects your stainless steel appliances.

Don’t use any “-ine” cleaners. Halogens, the chemicals that end in “-ine” are able to destroy the chromium oxide layer of your stainless steel appliances. Bromine and chlorine are two such chemicals that may be found in household cleaners.

Don’t use bleach. Bleach is an alkaline, or low pH chemical, that can compromise the protective layer of your stainless steel appliance.

Here are a few positive suggestions:

Rinse and dry your stainless steel after cleaning. In many cases, warm water is all you need to clean stainless steel. If you use anything else, make sure you rinse the surface with clean water. Drying it helps prevent minerals in the water from lingering.

Follow manufacturer’s instructions. Your owner’s manual will have specific instructions for the care of your particular model.

What To Do If You See Rust On Your Stainless Steel Appliance

If you, like many people, thought stainless steel was rust-proof, this article has been full of rather disappointing news. But now here’s the good news – you can remove small rust spots from your appliance, and stainless steel is self-healing!

This article from DIY Life explains some of the ways to do a good cleaning of stainless steel. Once the rust is removed and the surface dried, the oxygen in the air can once again work with the chromium to rebuild the protective layer.

While you may not always be able to keep a pure environment to for the protective layer to reform to its full strength, there is a good chance you can reverse the rust problem on your stainless steel appliances and enjoy them for years to come.