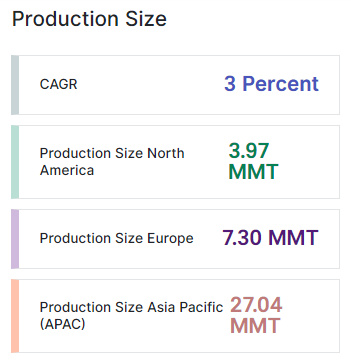

The stainless steel market has a production size of over 27 MMT in the Asia Pacific, more than 7 MMT in Europe, and over 3.9 MMT in North America. In total, global consumption was 42.6 MMT in 2018. There is a high likelihood that the total production size of the stainless steel industry will exceed 47 MMT by 2021. The CAGR is expected to be 3% in the future. The Asia Pacific is likely to be the dominant player that will continue to grow at a rapid pace. In 2017, more than 70% of the global stainless steel demand was from Asia and this trend is likely to continue in the future too. This was mainly due to the property sectors and the infrastructure sectors that grew in the area.

The stainless steel market has a production size of over 27 MMT in the Asia Pacific, more than 7 MMT in Europe, and over 3.9 MMT in North America. In total, global consumption was 42.6 MMT in 2018. There is a high likelihood that the total production size of the stainless steel industry will exceed 47 MMT by 2021. The CAGR is expected to be 3% in the future. The Asia Pacific is likely to be the dominant player that will continue to grow at a rapid pace. In 2017, more than 70% of the global stainless steel demand was from Asia and this trend is likely to continue in the future too. This was mainly due to the property sectors and the infrastructure sectors that grew in the area.

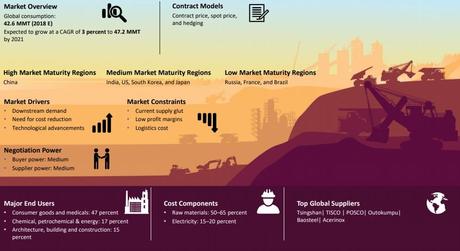

The top global suppliers of stainless steel are TISCO, POSCO, Acerinox, Tsingshan, Baosteel, and Outokumpu according to procurement intelligence experts Beroe. The high market maturity region is China. South Korea, India, Japan, and the US are medium market maturity regions. France, Brazil, and Russia are low market maturity regions. The components of stainless steel that define the cost of stainless steel in the market include the raw materials that account for anywhere between 50% and 65%. Another cost component that is important to note is that electricity. This component accounts for anywhere between 15% to 20% of the cost.

There are various stainless steel types and uses which is why it is in such high demand. It is one of the most used in kitchenware and cutlery as the different grades can be used for various applications. Power generation is another use of stainless steel because of its ability to combat corrosion when used with other materials. Automotive applications of stainless steel have made them an important component in that industry too. For example, one area of automotive requirement is exhaust systems that use stainless steel. Apart from this, the architecture industry uses stainless steel for roofing and cladding. This is one of the most useful applications.

Stainless steel uses extend to the medical industry too. Artificial hips and medical implants make use of stainless steel and so does medical equipment such as some machines. The pharmaceutical industry uses stainless steel too for various types of solutions. Another stainless steel application is in the food production and storage industry. The chemical, processing, gas, and oil industries have a requirement for stainless steel too. In fact, these industries are the ones that have a really high demand for stainless steel. As you can tell, the uses and applications of stainless steel are vast which is why this versatile material is always in such high demand.

Beroe's stainless steel industry analysis suggests that there are three main drivers of the stainless steel market. The downstream demand is a big factor when it comes to driving the market and the future will see more demand from downstream industries. For example, the construction industry and agriculture will have an increasing demand for stainless steel and this will help give a boost to the market. The second driving factor is technological advancements. New technologies are being created and developed to help lower the manufacturing process, boost production capacities and to increase efficiency. These are likely to drive the market too.

One of the primary factors for the growth of the stainless steel market is that there is an increase in modernization all over the globe. One of the areas that drive the growth of the market is the automotive industry. As the demand for stainless steel for the automotive industry will increase so will the market for stainless steel. Moreover, high investments in the manufacturing sector will lead to an increase in demand. As more nations' need for water and energy increases, the demand for stainless steel will increase alongside. This means that the growth of the market is likely to continue well into the future

There are constraints for the stainless steel market too and it will need to address this if it wants to ensure that the demands are met. One of the biggest constraints is the low-profit margins because of a decrease in prices. The cost of logistics is another constraint because these costs are generally high. This cost leads to an increase in steel costs and raw material imports. The landing cost of stainless steel is impacted as a result too. The supply of raw material is another constraint as any shortage will lead to steel production taking a hit. Strict quality measures and environmental concerns can affect the raw materials supply and this will affect production.