For most people, a spring is a spring, no matter what size it is. However, for those in the manufacturing business, the new wave springs are causing quite a stir as they can quite literally change the game! These wave springs prove that big power can come in small packages as they are half the size of a normal spring while still holding all the power that the big springs used to have.

Here’s why the next generation of wave springs is so important, and why the manufacturing world is very excited to get its hands on them.

What Has Changed?

Wave springs are a form of compression spring, which is a large spring that builds energy whenever it is pushed together. The harder you or an object pushes on the spring, the more force and pressure it exudes on the object. For example, compression springs are used in pogo sticks, where the harder you press down the higher you jump when the spring returns to its normal size!

These springs are used in manufacturing all sorts of items, but the problem with them is that they are very big and need to be big in order to work the way they do. While their size has worked for a while, as the world’s technology starts to get smaller and smaller, manufacturers are in need of a smaller and more compact string to keep up with the changing tech times.

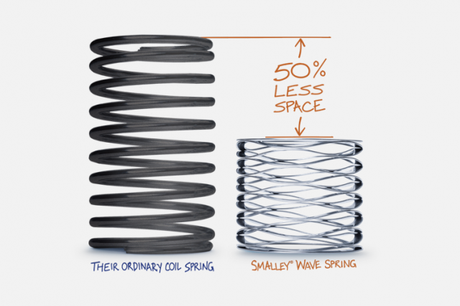

Smalley wave springs are the answer, because instead of the rounded coils of the traditional springs, the wave spring coils are flattened and each coil is strengthing with an arcing wave pattern for flexibility. This means that despite being lighter and smaller, the wave spring can produce the same force as its counterpart!

Wave Springs Can Be Used For Every Job

Wave springs have risen in popularity because of their extreme flexibility and versatility. The diameters can be changed, they can be made from virtuous materials, and can be configured to almost any task while still keeping the power they produce intact. From wave springs that work in your watch to wave springs that can work under the sea or in outer space, you are going to find a perfectly customizable spring for your job!

Additionally, wave springs can come in several sub-types for more specific assembly needs as well, and can be made of different materials.

For example, single turn wave springs are the most basic type of wave springs and they are able to be used in areas where the working space itself is very limited, while also permitting radial expansion and growth within a small cavity.

Nested wave springs are flat wire wave springs that are coiled together in parallel to produce higher forces, and they can easily replace large stacks of single-turn wave sprigs whenever the single-turn wave springs can’t produce the loads needed by the application.

In fact, a nested wave spring can have two to three times the force of a single-turn wave spring, and they are also able to be assembled cheaper and quicker into manufactured items. This means that those items are able to be assembled quicker, and then more customers can get their hands on them in order to continue the cycle!

How Wave Springs Are Changing Manufacturing

For starters, as this article has said, the wave spring is able to provide the same amount of force as a regular compression spring at half the size. This can be very helpful for manufacturers as they deal with products that have ever changing space constraints or need specific loading requirements. Additionally, they can have greater flexibility when designing products that a normal compression spring just wouldn’t allow them to have.

Plus, they also have lightweight assembly as well to save both time and cost when assembling materials, and the compact design can fit various tight spaces as well. All of this allows for items to get back off the assembly line and into the hands of the customers much faster, and for a cheaper price as well.

The world of technology is getting smaller and smaller, and it is only going to continue to shrink. This means that space for designs is becoming a premium and manufacturers need to take advantage of the space they do have any way they can. Items like wave springs will become increasingly more effective in the manufacturing world as more modern and compact technology is being designed.