I’ve been finding all sorts of really good films lately. The latest (and possibly greatest) is this one on English silk. Like last week’s video on Peal, this gives a rare look at one of England’s most important craft firms – David Evans & Co. David Evans was the last of the old London silk printers before they closed in 2002. During their 155-year history, they printed luxury silks on the banks of the River Cray for clients such as Holland & Holland and Drake’s.

The film takes us through David Evan’s factory, but it’s not really about David Evans per se. It’s actually about the last days of English hand block printing, which David Evans specialized in until the 1980s. Hand block printing is an incredibly slow, labor-intensive process that combines the skills of an artist, tool maker, and carpenter. In some ways, it’s the simplest and earliest method of all, and because of that, has more or less disappeared on a large-scale commercial basis (at least in England). Today, most of the silks you’ll handle have been either silk-screened or ink-jet printed. Those are obviously more efficient, but they arguably lack the humanistic, artistic edge of hand block printing.

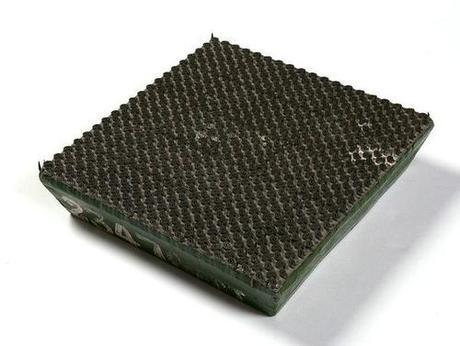

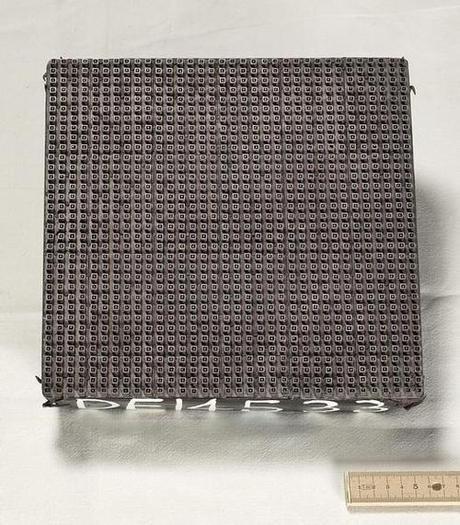

The process starts with a block maker, who transfers a design to a block of wood. A separate block is needed for each distinct color, so if you have a paisley design with five colors, then five blocks will need to be made.

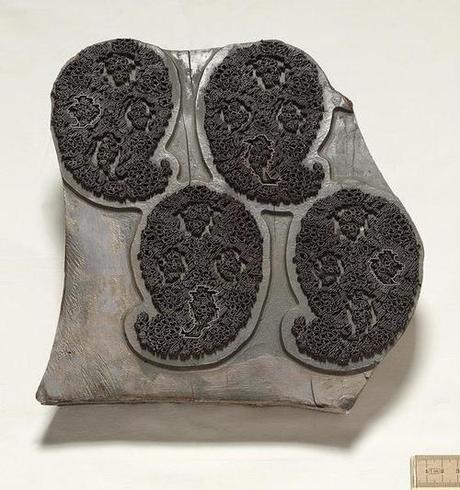

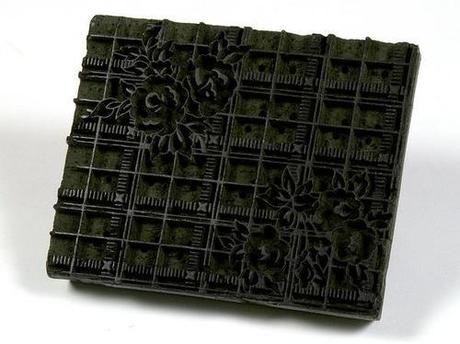

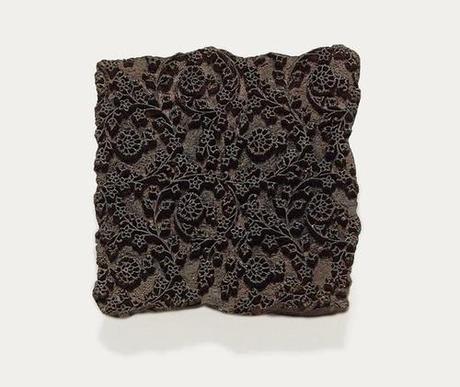

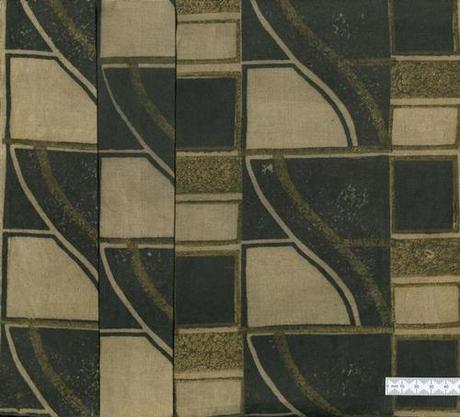

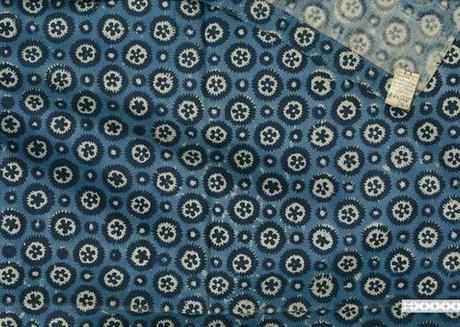

The blockcutter begins in the middle of the block and works outwards, first carving out the larger, coarser aspects of the design while leaving the finer details for last. This ensures that the smaller details won’t be damaged when he’s cutting out the larger bits. Fine details are very difficult to cut into wood, however, and even when successfully done, they can wear down rapidly or break off during the printing process. Thus, once a block has been made, the details are often reinforced with copper or brass, or just transferred to a metal plate. You can see examples from David Evan’s own archive below. The first design is a set of small paisleys and the second is a foulard with small, dotted squares:

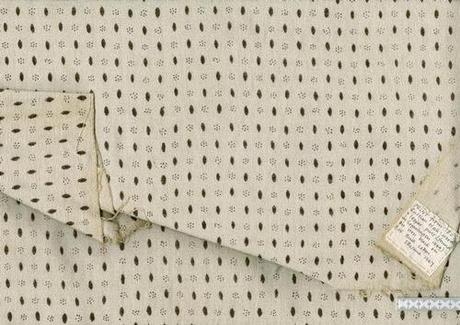

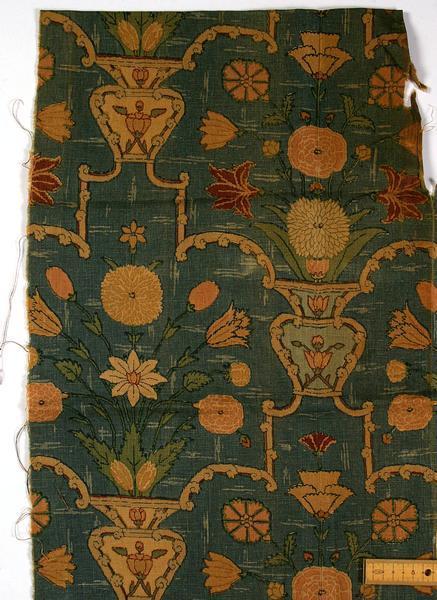

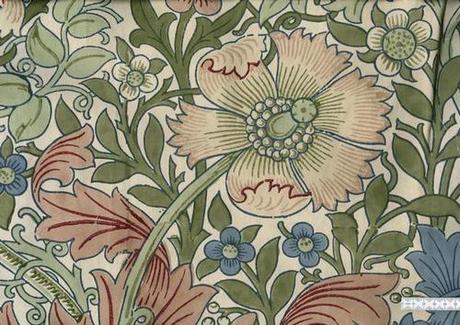

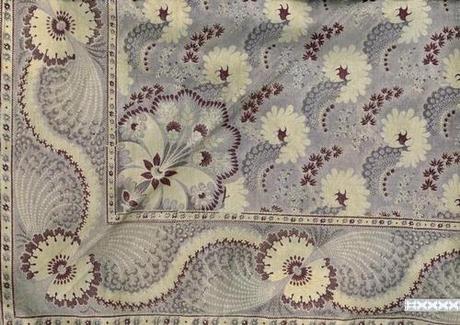

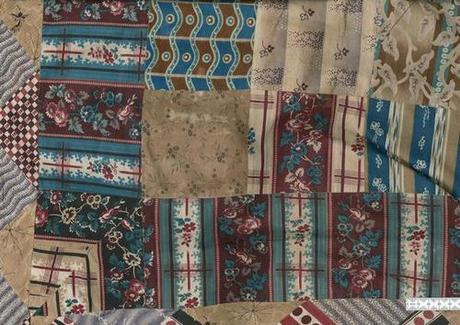

Once the plates have been made, a printer applies ink to the relief and hand presses it against a cloth. This has to be done firmly and steadily to ensure a good impression, and in the video, you’ll see the block is also tapped on with a wooden mallet. The second impression is done the same way, but has to be executed with incredible precision. If it’s sitting alongside the first print, the edges of the design have to align without a break. If it’s sitting on top of the previous print, it has to perfectly match up so that you don’t get a “3D effect.” To help with this, the printer relies on some small pin marks to correctly align each of his plates. When done well, you get something like these printed silks (which are also from David Evans’ archive).

David Evans & Co. had a massive library of such plates – something like 70,000 different blocks with about 11,000 different designs. Some were made by them and some came on a raft from France. The ones from France were paid for with money that the French would then use to pay off the Prussians after they lost the Franco-Prussian War. It’s unknown where the French blocks came from since many of their records were destroyed during the Siege of Paris.

Unfortunately, by the 1980s, the company ceased all their hand-block printing operations, and twenty-two years later, closed down completely. The printing technique ended partly because it wasn’t price competitive in the market and partly because few people cared about the craft. As you’ll hear in the video, some of David Evans’ customers complained about the pin marks found in the fabric (which, as you’ll remember, were used by the printer to align his blocks). Some connoisseurs actually looked for pin marks as evidence that a piece of material had been hand block printed, but most just wanted a “flawless” fabric. So in the end, the company switched to silk screening like everyone else.

The film is long, but informative, and gives a nice view of one of the most beautiful methods of textile printing in England’s history. You also get to see part of the production process for the company’s famous ancient madder silks (including the part where they wash the material with cow dung in order to affix the colors).

I’ve included a few more photos of printing blocks and hand-block printed fabrics below. The fabrics here include silks, linens, wools, and cottons. I’ve tried to stick to English fabrics, but there were so many beautiful French ones that I’ve mixed them in about 50/50. Just remember as you’re admiring the remarkably intricate details: these were hand done, one color at a time, with blocks.