In my limited experience, Tommy is a man of his word. At 9:30 he rolled up to the hotel, I threw my bag in the back of his SUV and we headed out. 20 minutes later we were standing in the courtyard staring at grain silos set against azure and ivory, the official Balcones Distillery tour had begun.

Now, silos aren’t all that interesting, you’ve seen one you’ve pretty much seen them all. The courtyard, on the other hand, was filled with a clanging cacophony of something that is interesting: the chain fed system they use to pull the grain, scoop by scoop, out of the silos and into the milling room.

A milling room that’s home to a roller mill, a hammer mill and a deafening racket. The roller mill spinning and crushing the malted barley into successively smaller uniformed pieces; the hammer mill crushing the corn, rye and other grains into small, but not uniformly sized, bits. Each producing a distinctively boisterous noise with the in-coming and out-going chain-and-scoop mechanism clanging in the background. A symphony of mechanized productivity.

The chain-and-scoop system left the milling room and went to storage tanks and/or a mash tun or cooker. The cooker shined and resembled a pressure cooker for a giant while the mash tun looked like a battered metal hut. The latter looked like it had seen a few tours of duty… and it had… in Scotland… at the Speyburn distillery.

They were making their single malt that day. Peeking insider we could see the malty 150 degree porridge resting. Allowing the natural malt enzymes to work on changing starch to sugar for the yeast.

From here we took a look at pumps and other equipment that was used to regulate temperatures and push material from one location to another. We followed one of those pumping tubes outside to their massive outdoor fermentation tanks. The day before, Winston and I had walked to the top to see the partially open fermentation tanks and get a better view of Waco.

Today, however, we stayed on the ground and talked about glycol jackets, 7 day fermentation times, 9-11% ABV outputs and removing the roof from this section of the old building to fit the fermentation tanks. As impressive as the setup is right now, it’s even more impressive that there’s still room for expansion without having to build an addition.

Looking around, it’s easy to think a distillery is nothing more than a series of tubes and tanks. And on a mechanical level that’s a fairly accurate assessment. But a distillery is more than that, it’s home to more than just connecting pieces of metal, it’s home to interesting people.

Back inside we headed towards the bottling operations and a feeling came over me, there was something different about Balcones. Not just their process and barrels, but their attitude. The way they thought about whiskey and spirits. How they approached their jobs with curiosity and appreciation.

A sense of “belonging” emanated from everyone I met. The people here seemed to enjoy their jobs in a way many never do. It’s an environment more intoxicating than the whiskey they were making.

The guy manning the dump tanks was just one of many faces that instantly felt familiar. Gregarious with a huge laugh, one second he was telling jokes, then next he’s talking about the technical aspects of the tanks and deciphering the codes for what was in them. After playing with some of the char from freshly dumped barrels we moved to the bottling line – a piece of every distillery I love seeing.

Watching the crew work quickly and efficiently to keep the line moving was like watching a partially mechanized ballet. Following the line, watching each step happen one after another. One party aware of what it took to get the final product out the door, aware of the passage of time and the exhaustion of a day.

The other simply moving to its programmed rhythm, existing only in states of working and not working. Humans and machinery moving in tandem to achieve the same goal.

We left the bottling room and headed through a dock and the sound of laughter followed us. Half the crew came back from lunch, bringing with them the punchline to a joke I’ll never know the setup for, but made me smile nonetheless.

In the dock, we looked at large packages of grain. Unlike their high volume grains, like malt and blue corn, smaller yield or experimental grains are delivered in large sacks which is how all of their grains were in the old facility.

These large parcels of grain are rarely seen in the big distilleries like Wild Turkey or Jim Beam; one of these would last less than a minute in their ravenous machinery. But I’ve found these bags of grain in every craft distillery I’ve been to. A marker of scale, but never of quality.

From there we left the main floor and climbed a series of stairs to get to the main attraction of this Balcones Distillery Tour, and every distillery tour really: the still room.

Still rooms are hot and loud and Balcones’ was no exception. They were running a batch of peated single malt this afternoon and a familiar smoky aroma greeted us as we opened the spirit safe for a better look. Sniffing a sample, and rubbing it in our hands to activate the volatiles suspended in the liquid, I breathed in the essence of their hard work.

Smiling, standing there, I looked up and stared at the coils above the stills and noticed they were different widths. It was like Tommy could read my mind, or maybe it’s just a common question, but unprompted he explained why they were there.

Back in the old distillery, their still had a 17 foot lyne arm on an incline. To replicate that in a vertical space, the folks at Forsyths came up with these coils. They figured out the angles and widths it would replicate best at and installed these coiled line arms on top of the stills.

There isn’t a hard-fast usage rule in place at Balcones, but when possible they run their malt whiskeys on the “faster” still. Faster being the one pictured above with the 4 turn coil and sporting an 8″ diameter lyne arm. Alternatively, when possible they run all of their American-style whiskeys on the “slower” still. Slower being the other still whose lyne arm sports 10 turns on the coil and a 6″ diameter.

From the still room it was off to see the next part of the process: barrelling and barrel storage. I noticed a distinct lack of a warehouse when we pulled up and I wasn’t quite ready for the answer to “where do you keep all your barrels?”. Turns out they have multiple locations.

In addition to having off-site storage for their barrels, Balcones stores a couple hundred on the fourth floor of their distillery. Rows and rows of barrels quietly aging while new barrels are being filled right below them.

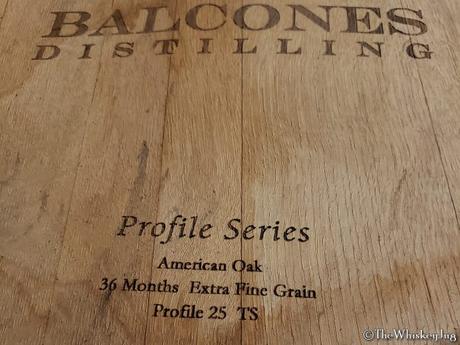

It’s been over three years since Balcones filled a barrel smaller than 53 gallons and at least two since the last ones were emptied. It’s all been large barrel whiskey since 2017 and they have no plans on going back. Though that doesn’t mean it’s all new barrels.

Looking through the racks I spotted some Four Roses barrels, among others, peeking out of the racks. Hordes of once used bourbon barrels now lending their profile to the single malt, corn whiskey, rums and experiments resting inside. The smell of this room, like in all rickhouses, is simply amazing.

Normally, this is where a tour ends. This is where the guide takes everyone down to the bar, tasting room or gift shop. We have a tasting, ask our hosts questions, recap answers and lay the foundation for the articles we’ll write in the coming weeks. And on the first day, with Winston, it did.

The tour started and ended at their bar where tasted through new expressions and their distillery-only white rum. But on day two we diverted. Tommy had other plans and we headed to the blending lab.

Go down two flights of stairs, head back towards the stills, make a sharp right and there, tucked away behind Master Distiller Jared’s office, is a room filled small bottles of whiskey.

Rows of samples with codes, notes and references covered the countertops. Atmospheric black metal snaked its way out of a speaker in the back while serious business was being conducted up front. Jared and another employee, who bore an uncanny resemblance to a co-worker back home, were taking notes and talking about some blinded samples.

The task at hand was picking the barrel mixes for the next batch of Balcones Rye; Tommy and I were immediately put to work. For Tommy this was every day, for me this was a unique and memorable experience.

One of the glasses help the last batch and the rest were different blends of barrels. It was my first time participating in something like this at a distillery. I’ve done plenty of tastings and whiskey deconstructions, but never sat in on a whiskey construction.

I’ve also attended barrel picks and understand the nuances and vast differences that can arise barrel to barrel, but it was still amazing to witness the change from adding certain barrels in or pulling certain ones out in the effort to construct the next batch.

We tasted, ranked, discussed pros and cons and then decided it was a good time for lunch.

After a quick meal we returned and were presented with another blind lineup. Some returning from the previous round and some new. This was to dial it in and see what adding or removing a few barrels would do. After another round of tasting and discussion, we made our picks and it was time for me to go.

On the way to the airport Tommy and I chatted about the past and future of Waco. Of the way it was adapting and changing and the ways it was staying the same. I’m all too familiar with living in small towns and when I’m stuck on the 405 I daydream about a simpler life in a smaller town.

In the past those thoughts would be a mix of the towns in Utah and Wyoming I was raised in and now they’ll include bits of Waco and the Texas sky. Boarding the small plane that would take me to Dallas, and then back to Los Angeles, I thought about the past two days and how it all came about.

I thought about my first taste of Balcones, almost 6 years ago, at a meeting of the Southern California Whiskey Club. About becoming friends with Winston through the same club. About surprising friends with Brimstone Old Fashioneds. About blind tasting surprises and the information of the last 48 hours.

I can’t say my opinion of Balcones has improved, I already loved them, but my understanding of the whiskey and the people has deepened and it’s impossible for that to not impact the drinking experience. It’s impossible to not see the faces and remember the sights, sounds and smells with each sip.

The days of small craft production are long gone, but the spirit and ideology that got them going is still there. It’s what made them exciting in the past and will continue to make them exciting as the craft segment matures and comes into its own.

They’ve always been a distillery I enjoyed and this Balcones Distillery tour further cemented that. They’ve been at this for a decade and show no signs of slowing. I think we’ve witnessed only the beginning of what they’ll continue to achieve and I look forward to what the future holds for this little giant.