Any kind of wood can be made into biochar by heating in a low-oxygen chamber. Some types

Any kind of wood can be made into biochar by heating in a low-oxygen chamber. Some typesof wood work better than others. Pictured, left to right, are white birch, white pine and

red cedar. (Credit: L. Brian Stauffer / University of Illinois at Urbana-Champaign)

While one team of researchers uses wood to create batteries, another proposes to use wood charcoal to make supercapacitors. Scientists from the University of Illinois at Urbana-Champaign report that wood charcoal supercapacitors can produce as much power as today’s activated-carbon supercapacitors at a fraction of the cost—and with environmentally friendly byproducts.

Batteries effectively store energy but do not deliver power efficiently because the charged carriers move slowly through the solid battery material. Capacitors, which store energy at the surface of a material, generally have low storage capabilities. Supercapacitors bridge the gap between conventional capacitors and rechargeable batteries. Supercapacitors currently cannot store as much energy as batteries, but are able to be charged and discharged much quicker. They also are distinguished from batteries by a much longer lifetime.

“Supercapacitors are ideal for applications needing instant power and can even provide constant power—like batteries, but at lower cost,” he said. They are useful in transportation, electronics and solar- and wind-power energy storage and distribution.

Many of today’s supercapacitors use activated carbon—usually from a fossil-fuel source, Jiang said.

“Costly and complicated procedures are normally used to develop the microstructures of the carbon—to increase the number of pores and optimize the pore network,” he said. “This increases the surface area of the electrode and the pores’ ability to rapidly capture and release the ions.”

In wood-biochar supercapacitors, the wood’s natural pore structure serves as the electrode surface, eliminating the need for advanced techniques to fabricate an elaborate pore structure. Wood biochar is produced by heating wood in low oxygen.

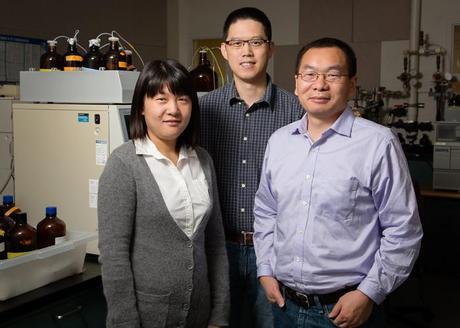

Researchers Lei Zhang, left, and Xinying Wang, center, with Junhua Jiang, a senior research engineer at the Illinois Sustainable Technology Center, are developing high-performance supercapacitors using wood biochar. (Credit: L. Brian Stauffer / University of Illinois at Urbana-Champaign)

The pore sizes and configurations in some woods are ideal for fast ion transport, Jiang said. The new study used red cedar, but several other woods such as maple and cherry also work well.

Expensive and corrosive chemicals are often used to prepare the activated carbon used in supercapacitors, giving the electrodes the physical and chemical properties they need to function well, Jiang said.

“The use of those chemicals will probably impose some environmental impacts,” he said. “This should be avoided or at least substantially reduced.”

Jiang and his team activated their biochar with mild nitric acid, which washed away the ash (calcium carbonate, potassium carbonate and other impurities) in the biochar. The byproduct of this process has a beneficial use, Jiang said: The resulting solution of nitrate compounds can be used as fertilizer.

These simple approaches dramatically cut the material and environmental costs of assembling wood charcoal supercapacitors.

“The material costs of producing wood-biochar supercapacitors are five to 10 times lower than those associated with activated carbon,” Jiang said. And when a biochar supercapacitor has reached the end of its useful life, the electrodes can be crushed and used as an organic soil amendment that increases fertility.

“The performance of our biochar materials is comparable to the performance of today’s advanced carbon materials, including carbon nanotubes and graphenes,” Jiang said. “We can achieve comparable performance with much less cost and probably much lower environmental costs.”

Junhua Jiang, Lei Zhang, Xinying Wang, Nancy Holm, Kishore Rajagopalan, Fanglin Chenb, Shuguo Ma (2013). Highly ordered macroporous woody biochar with ultra-high carbon content as supercapacitor electrodes Electrochimica Acta DOI: 10.1016/j.electacta.2013.09.121