Industrial Europe is currently going through a period marked both by strong competitive pressure from low-cost countries and a narrowing, a direct consequence of a consumption crisis in local markets. On the front line since 2008, the automotive sector was quickly forced to adapt and work on the flexibility of its model in order to maintain a robust economic performance.

To reduce Supply Chain costs, once the traditional levers have been activated (supplier negotiations, transport schemes optimization, inventory reduction, etc.), manufacturers have decided to go further by progressing on the notion of total cost.

The following summarizes some best practices for deploying such an approach that extends beyond the automotive industry.

The primary purpose of the total cost approach is to direct decision-making processes towards solutions that achieve a global optimum in the supply chain. Because of this systemic nature (opposed to function-based approaches), total cost is a fundamental concept of Supply Chain Management.

It is calculated by realizing the sum of assumed costs directly or indirectly by each function and this, until the service of the final customer:

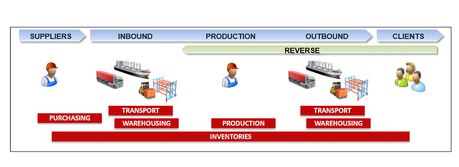

SCHEMA 1: Simplified representation of the Supply Chain + cost/ function source

The objective is to have the most exhaustive possible cost vision during its construction in order to measure the impacts (including those usually hidden) of a decision on all the functions of the chain.

In sectors where the value chain is shaped by large, long-term programs (vehicle programs in the case of the automobile), this approach is used in particular to optimize the current models during the serial lifespan. The total cost must be able to overcome breakthrough ideas by neglecting impacts on a function cost if the overall result is beneficial.

In the shorter cycle sectors (Consumer Product Goods, various industries), the approach is mainly used to: (i) build the right model at the start of production by supporting Make or Buy trade-offs, (ii) facilitate and optimize allocation decisions between logistics flow schema for each new product launch.

Recurring examples

By constructing the cost structure of the automotive supply chain, it quickly becomes clear that the weight of the upstream part, which consists mainly of transport from suppliers to factories, is substantial (around 40% of total logistics costs). The main driver of cost reduction, the improvement of the trucks/containers filling rate requires the implementation of transverse reflections such as total cost, in order to achieve solutions that are disruptive compared to the current models:

Supply-Transport arbitration:

Car manufacturers have all gone very far in terms of batch size in their various applications of Toyota’s precepts (see the concept of One Piece flow). However small lots have a double negative effect. On the one hand they no longer allow to optimize loadings (cost/m³ penalized accordingly).

On the other hand, they contribute to the frequencies increase and thus to the multiplication of journeys. The positive impact on the stock levels of the production units is, in this case, erased by the additional costs assumed by the transport function.

In this case, the use of the total cost makes it possible to dissociate (i) the high-value parts that have to be delivered on a daily basis in order to minimize their weight in the inventory (this gain covers the additional cost of transport induced) (ii).

The others parts that will be massified in transport at reduced frequencies (weekly if possible) to optimize loading rates (the gains largely covering here the differential on the storage cost).

Piece – transport manufacturing arbitration (design to logistics):

Still too little measured concretely in the industrial world but clearly identified at the operational level, the impact of the design phase on the logistics processes is an important subject to sift through total cost. Steering columns or exhaust lines are striking automotive examples. For pieces combining size and design complexity, the question of sub-component cutting (inducing an internal pre-assembly) must be systematically laid down on the basis of the different costs to be assumed.

It enables to dissociate (i) Pieces that make a relatively short journey in terms of km and / or that require a very complex assembly processor not mastered internally, these parts to be supplied by finished sets (ii) Pieces costly in transport (according to kms traveled and packaged volumes) and whose cost of internal pre-assembly is competitive, these pieces needed to be conversely decomposed into sub-assemblies during the design.

The idea of such a division is to be able to densify items within the same packaging and therefore to improve the cost/m³ ratio of transported goods; up to 30% in the case of steering columns or exhaust systems.

In other sectors, the exercise can be done around trade-offs between Marketing and Logistics functions, for example. In distribution, the total cost analysis of the ready-to-sell packaging on low cost ranges is not yet widespread while it poses interesting conclusions. These packaging, originally designed to reduce racking time, are very unstable to handle during all upstream stages and suffer from a markdown rate 4 to 5 times higher than warehouses level, thus penalizing the final cost customer rendering. On the other hand, on premium ranges for which the packaging is designed to be resistant, the loans to be sold can generate real savings and improve the customer experience.

Implementation keys

The transversality of the approach and the need to decide on a global optimum in break with the established scheme necessarily induces friction between trades still operating too much in a silos logic.

Here are main principles adopted by the builders to complete the process:

1 Make the dashboards consistent

Creating a total cost global objective that is common to the different functions and aligning each one’s objectives limit the blockages associated to diverging indicators and reduces the tension subjects.

2 Adapt the organization

The establishment of a steering unit of the topic of total cost at the general management level and the appointment of referents in each profession is a prerequisite to ensure effective project management. This one must promote the identification and implementation of concrete opportunities in the supply chain.

3 Define an arbitration body

The appointment of a top manager with the final decision-making power in case of blockage avoids having to recourse to the management committee continuously to decide. This decision-making power can even be given to the factory manager who is not only in charge of his productivity but also of the complete value chain of his vehicle.

4 Develop the actors supply chain maturity

The work basis, the training and the communication allow the operational ones to understand the direction that one gives to the use of the total cost tool.

Good reflexes

Moving forward with the total cost issues requires the ability to compile a large amount of data in a structured way and then use it to trigger arbitration.

For this, it is necessary to:

1 Structure cost models

If a good knowledge of all the applicable costs for each process is a good starting point, the goal must be to structure quickly generic cost models reproducing the different existing options and the total cost associated.

This point has already been developed by manufacturers but is also found in sectors such as large retailers under the name of rating grids. These ones enable to make a choice of logistic diagrams by comparing different possible scenarios. The first step in this case is to frame the potential channels (import, domestic stored, domestic cross dock, domestic direct for example) and the processes that they involve. The Supply Chain function saves the costs of each stage in parallel in the grid, with a particular focus on the processes known in advance for criticality and/or recurrence (typical example: what is the real cost of non-palletising the goods on import flows?).

The purpose of such a grid is to be able to automate and optimize the allocation of each new product in this or that sector according to the cost of the customer.

2 Facilitate Arbitration

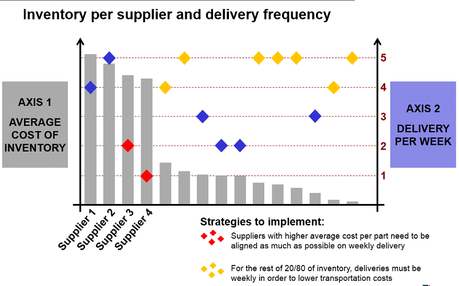

Extracting key data and presenting it in a synthetic form is the best way to create buy-in around a change scenario. On the batch size issues in the automotive sector, a summary vision of the stocks by supplier and the delivery frequencies used is a good example of an inventory comparing the production and transport trades:

SCHEMA 2 : Inventory vs frequency graph

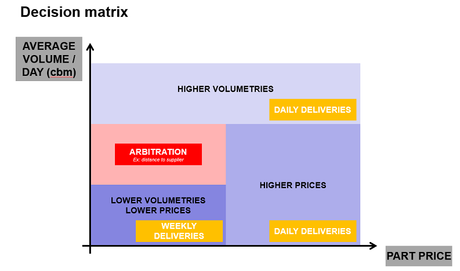

Behind the arbitration process, the use of decision matrices makes it possible to clearly share and validate main rules to be used to revise the management methods:

SCHEMA 3 : Volume delivery matrix vs pieces value

In the automotive sector, the introduction of this approach has already been proven to significantly reduce upstream logistics costs and thus improve the operating margin. It makes it possible to put on the table innovative scenarios of cost reduction by basing the final arbitration on the gain generated globally for the manufacturer.

This approach is starting to be deployed in other industrial and distribution sectors with real opportunities into the bargain. It requires setting up robust tools, adopting new management systems, and finally driving change within the company through targeted training and communication actions. For this, it must be the subject of a business project conducted by a dedicated team supported by the General Management.

Today, Supply Chain is critical in order to face the evolving expectations of customers who want to be served faster and with customized products.A flexible Supply Chain, supported by technology advancements, can help companies deliver products on unpredictable markets with more velocity and less variability.

Kepler’s Supply Chain consulting services support companies, creating high performing product flows with optimized cost and lead time.

113 total views, 2 views today