Engineered wood flooring is a variety of real wood floor made from a solid wood top layer and several layers of timber beneath. The layers are compressed to form an extremely rigid and durable board.

‘What is engineered wood flooring?’ is a common question we’re asked at Flooring 365. We are experts in all varieties of real wood flooring, including engineered wood. Discover what engineered wood flooring is and how it might work in your home.

Skip to Section:

What is Engineered Wood? | Variations of Engineered Wood | Engineered Wood vs Solid Wood | The Look of Engineered Wood Flooring | Where can I use Engineered Wood Flooring?

What is Engineered Wood?

Engineered wood goes through a process of ‘engineering’ to create a more durable and rigid board than achieved with standard solid wood. While solid wood flooring is ‘man made’, in that the boards have to be cut to size, sanded and finished, the material itself doesn’t need any construction before it can be turned into a floorboard.

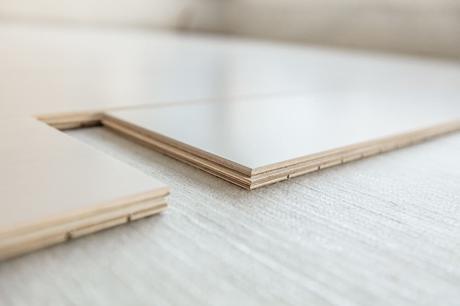

Engineered wood, on the other hand, is created from different layers of timber. The top layer is real wood, the same that creates solid wood flooring, but this is fused with layers of softer wood or HDF under high intensity conditions. This process of layering means the engineered wood floorboard has more durability. The layers allow the floorboard to adapt to changes in heat and moisture conditions without permanently shrinking or warping.

If you want high quality engineered wood flooring but are on a budget, our clearance sale offers the cheapest prices on quality flooring.

Ply

Engineered wood flooring comes in either multi-ply or three-ply - which describes the number of layers that create the floorboard. Multi-ply, with additional layers, has extra stability and is therefore the superior variety, but for this reason, usually costs a little more. Three-ply boards still offer high quality, stable and durable boards.

Varieties of Engineered Wood Flooring

As well as different number of layers engineered wood flooring has a lot of other variations. These include:

-

- Thickness: engineered wood flooring comes in thicknesses from 10mm to 22mm.

-

- Board length and width

-

- Wood species: both oak and walnut wood flooring is available

-

- Finish: everything from lacquered through to distressed.

-

- Installation variety: Click Lok or tongue and groove

-

- Colour: a massive range of colours are available including white, black and smoked.

Engineered Wood vs Solid Wood

Engineered wood and solid wood are similar in that they’re both created from real wood and look the same once fitted in your home. As discussed, the construction of the flooring is where the difference lies and this gives engineered wood several advantages over solid.

What is Solid Wood Flooring?

Solid wood flooring is made from a single board of real wood flooring, either oak, walnut or bamboo. This is cut into shape, sanded and finished to form a floorboard.

Stability: Moisture and Heat Resistance

As solid wood has only the single layer of hardwood, engineered wood with its multiple layers has more stability and resistance to both heat and moisture. While solid wood flooring will warp under changing heat conditions, as the wood shrinks or expands, the layers in engineered wood flooring allow it to shift without permanently altering its structure. This gives it more stability that solid wood flooring.

It also means that engineered wood flooring is suitable for use in conservatories, that face changing temperature conditions, as well as in rooms with underfloor heating.

Resanding and Finishing

There are common myths around engineered wood flooring that suggest engineered wood flooring can’t be resanded or surfaced - which is a great advantage of real wood flooring. It ensures that floors not only look great for the first couple of decades, but can be revitalised and given new life!

However, this is definitely a myth! The top layer of engineered wood flooring behaves in the exact same way as solid wood flooring. This means that it can be sanded and refinished when it begins to lose some of its shine or color. This won’t need to be done for a good decade after you fit your new floor!

The thickness of the top layer of the flooring, known as the veneer, dictates how many times the floor can be resanded. A 4mm veneer can be sanded approximately four times.

The Look of Engineered Wood Flooring

As engineered wood flooring is made with a top layer of real wood, it looks exactly the same as solid wood. Different aspects affect the appearance of the wood flooring: the wood species, the board width and length, the grain and the finish.

Wood Species

Flooring 365 have both oak and walnut engineered wood flooring options. These have very different appearances with oak being available in a wider range of colours. Walnut is a naturally darker wood option that has truly stunning rich tones. Oak is an age-old flooring choice that has so much variety that you’re bound to find your ideal flooring choice!

Board Width

The size of the plank impacts the way your room as a whole looks when the flooring is complete. If you have a smaller space, it’s often recommended you choose a narrower board width. This tricks the eye into seeing the space as bigger than it is!

Grade

The grade of the grain is not a quality measurement, as a lot of people believe, but instead simply impacts the appearance of your final floor. The grain of the floor describes whether it appears smooth, ‘rustic’ (with knots and variations) or distressed - a much rougher variety of floor that’s fantastic for bringing character into your room.

Finish

The finish of your engineered wood is one of the key factors that influences the look of the final floor. A lacquered finish creates a highly durable floor that’s extremely shiny, while a oiled floor has a more natural appearance. Your personal taste, and the demands of the foot traffic, impact which flooring finish will work best for you. A smoother flooring choice is very popular with more contemporary interior design, while a brushed finish is popular for a rustic appearance.

Where to Use Engineered Wood Flooring

Engineered wood flooring can be used in both homes and commercial spaces. With the massive range of different finished available, it can be protected for high levels of foot traffic (a lacquered finish) or left more natural for lower levels of foot traffic (oiled finished). The construction of engineered wood flooring means it can also withstand changing temperature and moisture conditions, making it suitable for a wider variety of spaces.

Engineered wood flooring:

✓ Kitchen

✓ Conservatory

✓ Living room

✓ Dining room

✓ Bedroom

✓ Office

✓ Hallway

Solid Wood Flooring:

✗ Kitchen

✗ Conservatory

✓ Living room

✓ Dining room

✓ Bedroom

✓ Office

✓ Hallway

Underfloor Heating

If you have an underfloor heating system, engineered wood flooring is the perfect choice. While real wood flooring would warp if it was exposed to such intense heat, engineered wood flooring remains undamaged. It’s the perfect way to get the look of a real wood floor even with an underfloor heating system.

Be careful to choose the right engineered wood flooring thickness if you use underfloor heating. It has to be thin enough that the heat can effectively penetrate the wood and enter your room - up to 15mm.

What is Engineered Wood Flooring?

If you have any additional questions about engineered wood flooring, we would love to hear from you. Use our chat box to talk with an expert right away, give us a call on 0333 002 0175 or drop us an email: [email protected].

Flooring 365 have one of the biggest ranges of engineered wood flooring available online and the very best prices. If you’re on a budget and want quality flooring, check out our clearance sale!