Singer 31K15 industrial sewing machine looking for a new home | #LRCrafts - DIY Passion: if you can think it, you can make it

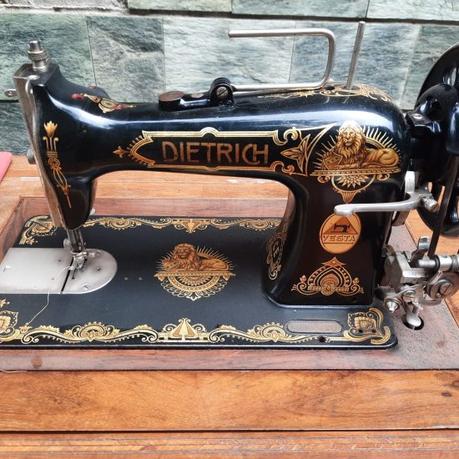

As I shared in a previous post, we rescued two treasures from my husband’s grandmother’s home: two ancient sewing machines. One was a Vesta Dietrich from the early 1930s, the other a Singer 31K15 industrial machine from 1915. This was her lifelong stitching companion, and it has its own story to tell.

I remember the first time I laid eyes on it, in granny’s dining room: a sturdy, reliable piece of equipment that had clearly seen its fair share of use. Back then, I had no clue about the history of such old machines. I wasn’t even into sewing yet. Now, I know a lot more about the craft and about these ancient machines, which remain so reliable despite their age. And I also know much more about their history, having dived deep into their past.

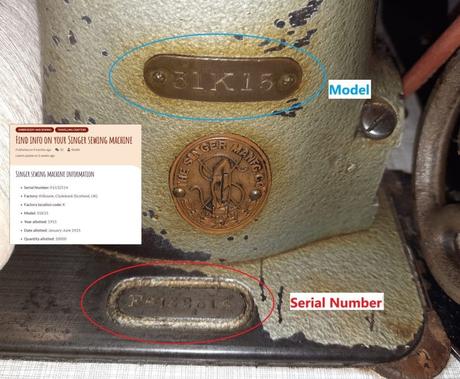

Thanks to the extant Singer serial number records, I was able to date granny’s Singer machine: it was made in 1915 in the Scottish factory of Kilbowie, one of the two biggest Singer factories in the world.

But this machine has more to tell than just its age. A badge on the main body identifies the model as a 31K15: an industrial machine, the kind you’d expect to find in a factory. And indeed, this machine came from a shoe-making factory.

Table of contents

The story behind this sewing machine

Granny’s relationship with her Singer 31K15 began many years ago in a shoe-making factory in her town, a place with a long-standing tradition of shoe production. She first worked on the machine there, at the factory, sewing shoes. Later, when the factory allowed her to work from home, she was able to take the machine with her. When she finally retired, she got to keep it. From what I’ve heard, this was a common practice for many sewists who had spent years working on these machines.

For granny, this machine wasn’t just a tool like any other: it was the machine she trusted, the one she knew best. She never wanted a newer one, despite the availability of more modern and affordable models.

In fact, we saw granny’s Singer 31K15 in action more than once. My husband and I had her help with our first historical clothing endeavours: Locutus’s first Celtic tunic, for example, to which she added trimming. Later, at the end of 2022, when my husband and I made a bench for our new home, granny was there again, using the same Singer to sew the upholstery. It’s amazing to think that she used this machine for decades, through all sorts of projects, and it never let her down.

Well, after granny passed away, we all went to her house to see if could keep something as a keepsake. I was, of course, interested in what would happen to her Singer sewing machine, but to my astonishment, I discovered the Vesta Dietrich as well. I was able to bring both of them home, but unfortunately, we don’t have space for them all.

I knew they had both been well-loved and carefully maintained. The Singer 31K15 now resides in our basement, and I feel sad we can’t operate it anymore, after all those years in service. I’ve come to the decision that it would be better off in the hands of someone who can love and use it, rather than sitting in our basement as a silent heirloom.

So, if you’d like to have it, step forward and contact us.

Looking through the Singer serial number database, I found that this machine was part of a batch of 10.000, allotted in 1915 in the Kilbowie factory in Scotland, all destined to become class 31 machines. As the badge on the machine itself indicates, ours became a 31K15, with the “15” marking its specific variant.

That’s the first industrial machine I came accross, and it sparked my curiosity. How does an industrial model like this differ from its domestic counterparts? What makes it ideal for the heavy-duty work granny performed in the shoe-making industry?

About industrial sewing machines and the 31-class

As the term implies, industrial sewing machines were designed for heavy-duty use in factories, where requirements are stricter than for domestic machines. They were also built to sew at high speeds while remaining durable, making them ideal for production work.

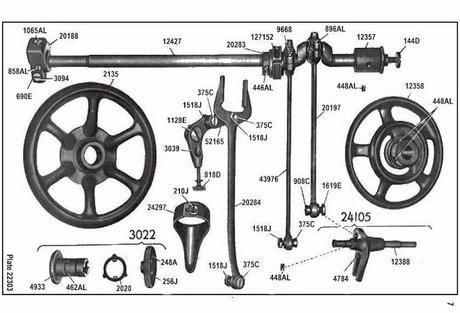

The Singer 31 class was designed for high-speed lockstitching on both cloth and leather, making it a staple in factories and tailoring workshops. Known for its stability, efficiency and durability, this machine required less power to operate than others in its category, thanks to carefully balanced moving parts and a scientifically distributed metal frame that minimized strain.

One of the defining features was its oscillating shuttle mechanism. This system efficiently converted rotary motion into oscillating movement, without requiring variable speed adjustments or indirect mechanisms. As a result, the machine ran smoothly and efficiently, allowing for the use of lighter, weaker, and consequently cheaper thread than any other high-speed machine.

The link thread take-up mechanism consisted of a light yet strong lever and link, operating silently without the need for a cam or spring. This innovation enabled the machine to function at high speeds with minimal friction and wear, while also reducing vibrations for a smoother sewing experience.

With the knee-lift mechanism, operators could raise the presser foot hands-free, improving workflow efficiency. Additionally, the automatic tension-release system worked in sync with the presser-foot lever, ensuring that the upper thread could pass freely when needed. This prevented thread withdrawal issues, maintained correct tension at all times, and further increased productivity.

This Singer 31K15

Our Singer 31K15 still retains much of its original setup. It comes with its original table, which features an incorporated ruler, a practical addition for precise measurements directly at the workstation.

The machine is also equipped with its original lamp, useful to have proper illumination for detailed work. Over time, it has been motorized to enhance its efficiency. This could make it more suitable for modern use, mainly if you – like me – haven’t grasped yet how to operate a treadle.

The table legs and treadle are made of metal, designed to be sturdy and withstand the demands of high-speed operation. Along with the machine, the drawer preserved a selection of accessories, including a set of bobbins and additional presser feet, notably its original roller foot, which was essential for sewing leather and other challenging materials.

Let's find it a new home!

This machine is indeed a true workhorse, built to handle demanding sewing tasks with precision and speed. In many ways, it’s more than I truly need, and I hope to find someone who can appreciate its capabilities and put it to work at its full potential.

Letting it go won’t be easy, since it’s a cherished memory of Granny and the skills she passed down to my husband, but I’ll be happy if it finds the right hands, someone who understands and values what this machine was made for.

If you’re interested, feel free to contact us. I’d love to see it go to someone who will truly make the most of it.

Resources

- Singer industrial sewing machines manuals (ISMACS)

- Singer industrial sewing machines manuals (SingerSewingInfo)

- About the Singer class 31

- Database of vintage Singer sewing machines serial numbers, plus info about serial numbers, factories and location codes, class and model numbers

- On the history of Singer company

More on our vintage sewing machines

Singer 31K15 industrial sewing machine looking for a new home

Manuals for vintage Singer sewing machines

Found a vintage Vesta Dietrich sewing machine: discovering a piece of history

Vintage Singer sewing machine welcomed in the family

by Rici86.