New plasmonic metamaterials that operate at high temperatures could radically improve solar cell performance and bring advanced computer data storage technology that uses heat to record information on a magnetic disk.

The materials could make it possible to harness clouds of electrons called surface plasmons to manipulate and control light. However, some of the plasmonic components under development rely on the use of metals such as gold and silver, which cannot withstand high temperatures. They also are not compatible with the complementary metal–oxide–semiconductor (CMOS) manufacturing process used to construct integrated circuits.

Purdue University researchers are working to replace silver and gold with titanium nitride and zirconium nitride.

“These materials remain stable at the high operational temperatures required for high efficiency and performance,” said Urcan Guler, a postdoctoral research associate working with Alexandra Boltasseva, an associate professor of electrical and computer engineering, and Vladimir M. Shalaev, scientific director of nanophotonics at Purdue’s Birck Nanotechnology Center and a distinguished professor of electrical and computer engineering.

The promise of high-temperature plasmonics is described in an article in the journal Science (see footnote). The article, appearing in the magazine’s Perspectives section, was co-authored by Guler, Boltasseva and Shalaev.

Metamaterials have engineered surfaces that contain features, patterns or elements, such as tiny antennas or alternating layers of nitrides that enable unprecedented control of light. Under development for about 15 years, the metamaterials owe their unusual potential to precision design on the scale of nanometers.

Now, researchers have discovered that a new class of plasmonic technologies might use high temperatures to achieve superior efficiency. One obstacle, however, is that the operational temperature required for high-efficiency devices is estimated to be around 1,500 degrees Celsius (about 2,700 Fahrenheit). Titanium nitride and zirconium nitride are said to be refractory, meaning they have a high melting point and chemical stability at temperatures above 2,000 Celsius (about 3,600 degrees Fahrenheit).

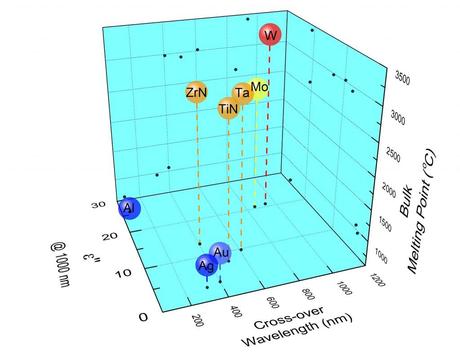

This diagram shows the respective properties of plasmonic and refractory materials for applications in high-temperature plasmonics, which could radically improve solar cell performance and bring advanced computer data storage technology that uses heat to record information on a magnetic disk. (Credit: Birck Nanotechnology Center / Purdue University)

The plasmonic metamaterials might be used for solar thermophotovoltaics, in which an ultrathin layer of plasmonic metamaterials could dramatically improve solar cell efficiency: Whereas today’s solar cells have an efficiency of about 15 percent, in theory the efficiency might be improved to as high as 85 percent with solar thermophotovoltaics. The plasmonic layer acts as a thin “intermediate spectral converter” that absorbs the entire spectrum of sunlight and then illuminates the solar cell, Guler said.

The spectral converter is an extremely thin layer of metamaterial that uses plasmonic nanoantennas to absorb and emit light. The layer might be as thin as 500 nanometers, or half of a micron, roughly one-hundredth the width of a human hair. This layer of material would be heated by sunlight to about 1,500 degrees Celsius.

Previous research in the field explored the use of refractory metals such as tungsten or tantalum, which are not good plasmonic materials. Using these metals requires a layer 20 times thicker than is possible with the plasmonic metamaterials, making it far more vulnerable to mechanical stresses caused by the constant expansion-contraction cycle of solar thermophotovoltaic devices. Another advantage is that the thinner layer heats up more readily because of its low mass.

The high-temperature plasmonic metamaterials also could enable researchers to perfect a new form of computer data storage called heat-assisted magnetic recording (HAMR) drives, which promise far greater capacity than is possible with current technology. However, one challenge is to create nanoantennas out of materials that stand up to the extreme temperatures and mechanical demands posed by the operation of computer hard drives, Shalaev said.

“The antenna is located very close to a disk spinning at a high speed and under temperatures of about 400 Celsius,” he said. “Under these conditions, deformation of the nanostructure is difficult to prevent.”

Titanium nitride, however, offers high strength and heat resistance. The material is used commercially to coat drill bits.

“There is no way to damage it with a spinning disk,” Guler said.

Shalaev and Boltasseva have formed a startup company, Nano-Meta Technologies Inc., based at the Purdue Research Park. Nano-Meta Technologies is focusing initially on three applications: the heat-assisted magnetic recording, solar thermophotovoltaics and a new clinical therapeutic approach.

Guler, U., Boltasseva, A., & Shalaev, V. (2014). Refractory Plasmonics Science, 344 (6181), 263-264 DOI: 10.1126/science.1252722