A phone call from Bloggers Mind about an invitation to visit PepsiCo snacks plant in Kolkata made my mind wander to the childhood days where we were taken to industrial visit and with the same childlike curiosity I consented to be part of the trip. My kids obviously not only wanted me to get them few packets of Kurkure and Lays fresh from the facility but also wanted me to make the batch for them.

A phone call from Bloggers Mind about an invitation to visit PepsiCo snacks plant in Kolkata made my mind wander to the childhood days where we were taken to industrial visit and with the same childlike curiosity I consented to be part of the trip. My kids obviously not only wanted me to get them few packets of Kurkure and Lays fresh from the facility but also wanted me to make the batch for them.

An early morning flight offering some clear cloud views from the top marked our arrival in Kolkata that got a non season rain in November. The coach that came to pick us had interesting driver(s), but will tell you that story some other time. For the time being it will just suffice to add that in a hour journey from airport to Dhulagarh they not only left a long lasting impression on our mind but also made the journey fun (if that’s the term I can use for someone who made us smile even though we were concerned with the way they did their duty).

An early morning flight offering some clear cloud views from the top marked our arrival in Kolkata that got a non season rain in November. The coach that came to pick us had interesting driver(s), but will tell you that story some other time. For the time being it will just suffice to add that in a hour journey from airport to Dhulagarh they not only left a long lasting impression on our mind but also made the journey fun (if that’s the term I can use for someone who made us smile even though we were concerned with the way they did their duty).

We arrived at the plant and after the warm welcome were made to go through a security video. Later the presentation by Vani Gupta (Kurkure Marketing Director) made us go through the portfolio of the brand that has over 70 variants and 110 SKU’s. Without disclosing the exact sales number, Vani mentioned that Kurkure that started in 1999 now sells more packets then India’s combined population, giving an idea about the strength of the brand. It was also good to know that Kurkure is India’s first indigenous brand to go abroad.

We arrived at the plant and after the warm welcome were made to go through a security video. Later the presentation by Vani Gupta (Kurkure Marketing Director) made us go through the portfolio of the brand that has over 70 variants and 110 SKU’s. Without disclosing the exact sales number, Vani mentioned that Kurkure that started in 1999 now sells more packets then India’s combined population, giving an idea about the strength of the brand. It was also good to know that Kurkure is India’s first indigenous brand to go abroad.

Niteen Pradhan (VP- Operations) on the production lifecycle starting from the creating tuber and tying up with farmers for a long lasting relationship where they help then with technology, getting loans, saving the production from various diseases like late blite etc. PepsiCo currently has tie-ups with over 24,000 farmers across India of which 50% are in West Bengal itself. Another thing I learnt here that the potatoes used in the making of potatoes are the process grade potatoes and not the table grade potatoes that we use in our cooking.

Niteen Pradhan (VP- Operations) on the production lifecycle starting from the creating tuber and tying up with farmers for a long lasting relationship where they help then with technology, getting loans, saving the production from various diseases like late blite etc. PepsiCo currently has tie-ups with over 24,000 farmers across India of which 50% are in West Bengal itself. Another thing I learnt here that the potatoes used in the making of potatoes are the process grade potatoes and not the table grade potatoes that we use in our cooking.

These potatoes are high in solid content and less on water unlike the one we use on our home cooking. Hence if one has to boil these potatoes, it will take much-much longer. I kept noting all statistics while munching the new flavor West Indies Hot ‘N’ Sweet Chilli which is not available in Delhi as yet.

These potatoes are high in solid content and less on water unlike the one we use on our home cooking. Hence if one has to boil these potatoes, it will take much-much longer. I kept noting all statistics while munching the new flavor West Indies Hot ‘N’ Sweet Chilli which is not available in Delhi as yet.

Post that we changed to the official attire including changing shoes and had to put mask to ensure we do not adulterate the food supply in any which way. The watch had to be taken off and gloves were provided to those who rings were not coming out.

All this to ensure no foreign particle becomes part of the consignment that was being produced. Impressed with their commitment to ensure hygiene, I wanted to see the storage and the quality of ingredients used in making the namkeens.

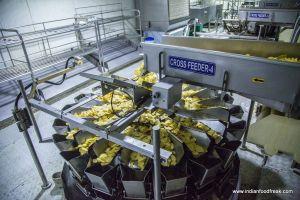

The plant has minimal manual intervention. The only 2 points where any human touch is required is to check the potatoes once they are peeled by the machine to check the quality and then at the last stage where packets are put in the cartons.

The plant has minimal manual intervention. The only 2 points where any human touch is required is to check the potatoes once they are peeled by the machine to check the quality and then at the last stage where packets are put in the cartons.

Besides this the entire production is automated from peeling, cutting, washing, frying, drying, mixing appropriate seasoning to packaging. The automated plant is so effective that the laser camera in a fast and precision way removes every single chip that does not meet the criteria by passing light through every chip. For example, any chips with extra sugar will turn brown on frying and the machine is built to remove every one of them.

Besides this the entire production is automated from peeling, cutting, washing, frying, drying, mixing appropriate seasoning to packaging. The automated plant is so effective that the laser camera in a fast and precision way removes every single chip that does not meet the criteria by passing light through every chip. For example, any chips with extra sugar will turn brown on frying and the machine is built to remove every one of them.

We were impressed by the way products are stored and hygiene standards maintained. In fact leave behind we getting an opportunity to make the batch ourself, we were not even allowed to taste the live batch.

We were impressed by the way products are stored and hygiene standards maintained. In fact leave behind we getting an opportunity to make the batch ourself, we were not even allowed to taste the live batch.

The plant also works for conserving energy. The rice husk from the farm is used to power the entire frying facility for heating oil, Bio methane is used generate power for the plant and it even uses waste steam and fryer stack steam in chilling plants to save on fuel. Good to know that the company is making efforts to reduce carbon imprints.

My only question to them was when we would see the empty plastic bags going a bio degradable way for which I was told that company has planned this as a major focus initiative for vision 2025. The technology is not available worldwide and I do hope that they soon get it.

Last but not the least, my kids are very fond of Kurkure and Lays, however as a responsible parent, I’ve been a bit concerned off late given all the controversies around Kurkure having plastic content. We checked the entire storage and saw the ingredients getting mixed to make Kurkure and chips. I noted the ingredient list and realised besides quality corn, rice, gram, oil and spices there is nothing that got added in the entire process that can be unhealthy for any family. Post coming back from the plant I also spoke to my friend, Anil Jadhav who is the MD of EcoCert India, an inspection and certification company for agricultural products headquartered in France about his opinion about the controversy.

Last but not the least, my kids are very fond of Kurkure and Lays, however as a responsible parent, I’ve been a bit concerned off late given all the controversies around Kurkure having plastic content. We checked the entire storage and saw the ingredients getting mixed to make Kurkure and chips. I noted the ingredient list and realised besides quality corn, rice, gram, oil and spices there is nothing that got added in the entire process that can be unhealthy for any family. Post coming back from the plant I also spoke to my friend, Anil Jadhav who is the MD of EcoCert India, an inspection and certification company for agricultural products headquartered in France about his opinion about the controversy.

Anil denied that anything unwanted is there in the pack. It reminded me of the controversy with Maggi Noodle where FSSAI had banned the product for some time. Am sure if the controversy was half true, Kurkure would have faced similar action.

This visit certainly helped clear all my doubts. It’s completely safe and fun to share a pack with family and friends. Happy munching!