Setting the Incinerator for Optimized Combustion

The combustion process requires the three elements to be combined and balanced within the system for efficient combustion of waste: oxygen, heat, and fire.

The above image shows the combustion triangle. If any one of these elements within the triangle are removed, the combustion process stops. If the elements within the triangle are compromised, then the combustion process is not optimised and generates increased carbon monoxide (CO), reduction of heat, reduction of waste burn rates.

If too much air is in the combustion process this will result in other gases will be created like nitrogen oxide, Sulphur dioxide etc.

Moisture Content

The simple rule to of thumb Is that low moisture content supports an increase in burn rate. Inciner8 utilise industry best practice to advise on the €œbest case scenarios for burning waste. Inciner8 recommend a moisture content of <15% for optimum combustion characteristics.

To summarise:

- Water does not burn

- Ash is dry, meaning you are using energy and time to get rid of water from the waste stream

- If the waste is dry at the beginning of the process, energy and time consumed to get rid of water would be used for burning the actual waste instead, hence overall burn rate would be higher.

Size Matters

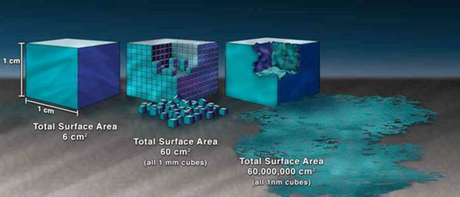

It is important to try and reduce the waste into sizes which increases the surface area of its component parts. To achieve the best and most effective combustion is done through exposing the largest surface area to high temperature. This allows the quicker introduction of heat and oxygen to each particle and allows for fuller and complete combustion to take place.

The decrease in size and the increase on surface area allows heat and oxygen molecules to interact with the waste fuel.

The advantage of this is that it allows the right amount of oxygen to be introduced into the combustion process, which ensures that the waste fuel is adequately combusted and that any surplus oxygen is controlled so that it will not combine with other elements, and thereby minimise pollution. The smaller the pieces of the waste the increase in the relevant surface area exposed to the high incinerator temperatures.

The above image shows how the reduction of particle size increases the surface area.

This is part 4 of a 6 part series on “Everything You Need to Know About Incineration”, brought to you by our expert technical team at INCINER8.

Click the links below to read:

- Part 1: What Is an Incinerator?

- Part 2: Different Waste Types & What Can Be Incinerated

- Part 3: Optimizing Combustion

- Part 5: Pollution Control Systems

- Part 6: Training and Operation of an Incinerator