(Credit: Flickr @ Jay-P https://www.flickr.com/photos/esqenzo/)

(Credit: Flickr @ Jay-P https://www.flickr.com/photos/esqenzo/)While porous hydrophobic/oleophilic materials (PHOMs) show promise for cleaning up oil spills, such a cleanup would require a large quantity of PHOMS due to their limited absorption capacity. Chinese scientists have now proposed a way to solve this problem.

A team led by Yu Shu-Hong at the Hefei National Laboratory for Physical Sciences at Micrscale (HFNL) at the University of Science and Technology of China (USTC) has created a new type of an oil collection device based on a simple combination of a hydrophobic polymer sponge (HPS, a typical PHOM) with pipes and a self-priming pump, that can continuously and selectively collect oil in situ from a water surface with high efficiency.

SEE ALSO: Scientists Fingerprint Oil from Deepwater Horizon Spill

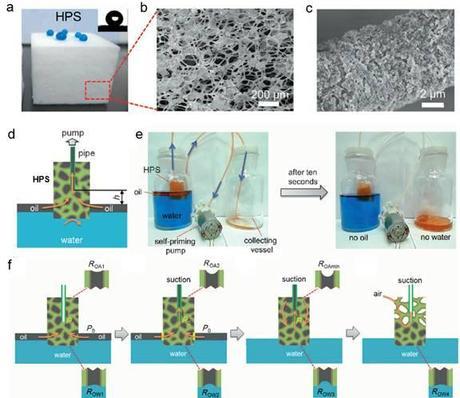

(a) Image of the as-synthesized HPS; inset: water contact-angle measurement of the HPS. (b, c) SEM images of the HPS with low and high magnification. (d) Oil transportation mechanisms with the HPS fully filled with oil. (e) Photographs of continuously collecting n-hexane in situ from a water surface by our proposed oil connecting apparatus. (f) Capillary pressure changes in the oil–air and oil–water interfaces of the HPS during the suction process. (Credit: See citation at the end of this article)

Key to this design are the capillary pressures at oil-air and oil-water interfaces of the HPS that spontaneously regulate with the suction power applied to the HPS and the unique interconnected macropores of the HPS that ensure sufficient oil flow inside the sponge.

The oil-air and oil-water interfaces prevent the permeation of air and water to the HPS, so that only the floating oil is absorbed by the HPS and flows along the pipes to the collecting tank, leaving the HPS consistently able to uptake more oil.

Here’s how the USTC press-release describes the advantages of the new method:

This oil collection design saves sorbents, labor, and operation time, and as a result largely decreases the cost of oil collection. In the future, for large-area oil spills, oil-collecting ships could “fish” the floating oil by pulling a large floatable oil collection net made of hydrophobic polymer sponges and pumps. This foldable oil-collection net with unlimited oil-sorption capacity, small in volume, and easy to carry, may also be used as emergency facilities for tankers and drilling platforms in case of oil leakage.

The research project is sponsored by the National Basic Research Program of China, the National Natural Science Foundation of China and the Chinese Academy of Sciences.

Ge, J., Ye, Y., Yao, H., Zhu, X., Wang, X., Wu, L., Wang, J., Ding, H., Yong, N., He, L., & Yu, S. (2014). Pumping through Porous Hydrophobic/Oleophilic Materials: An Alternative Technology for Oil Spill Remediation Angewandte Chemie, 126 (14), 3686-3690 DOI: 10.1002/ange.201310151