Illustration source: Nature

In a vicious, and competitive market, solar energy production can only stand the tide by reducing its costly production, and installation margin. Recent studies indicate that the cost to manufacture, install and maintain solar panels is on a continues rise -- this means affordability will increasinglybe an issue as consumers find it more and more difficult to finance installing solar panels on their properties.

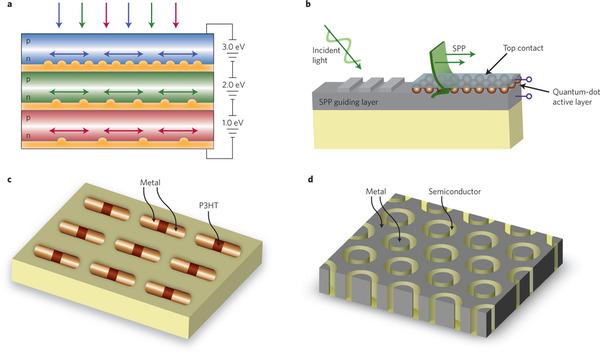

An article in the May 7th edition of the journal 'Advanced Materials' details how plasmonic-enhanced organic photovoltaic materials are used to produce more power with reduced manufacturing costs. The researchers intend to produce thin solar cells from organic materials -- which are liquid based with greater potential in applicability, cost and efficiency.

"Currently, solar power is produced with either thick polycrystalline silicon wafers or thin-film solar cells made up of inorganic materials such as amorphous silicon or cadmium telluride. Both are expensive to manufacture",..."Compared with their inorganic counterparts, organic photovoltaics can be fabricated over large areas on rigid or flexible substrates potentially becoming as inexpensive as paint, -- and their power conversion efficiency needs to be 10% or more to compete in the market," says Qiaoqiang Gan, the University at Buffalo assistant professor of electrical engineering -- helping with the research (ref).

Gan is successfully achieving the 10% by combining metal nano-particles and plasmonic nano-structures with organic photovoltaic cells. The researchers caution that the theory of paint should not be taken literally but as a descriptive term that means solar panels may one day be easily installed as paint application.

Original Article: Advanced Materials