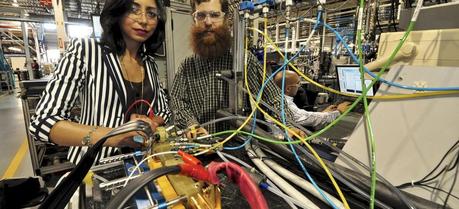

A team of SFU student researchers is at work at Ballard Power Systems in Burnaby carrying out tests to improve fuel cell durability. (Credit: Simon Fraser University)

Researchers working to improve durability in fuel cell powered buses, including a team from Simon Fraser University, have discovered links between electrode degradation processes and bus membrane durability. The team is quantifying the effects of electrode degradation stressors in the operating cycle of the bus on the membrane lifetime.

The findings of the study, called Membrane Durability Testing for Heavy Duty Bus Fuel Cells, led by SFU graduate student Natalia MaCauley, are the latest in a long-term study at Burnaby-based Ballard Power Systems and funded by Automotive Partnership Canada that aims to make fuel cell buses competitive with diesel hybrids.

The proposed heavy duty bus specific accelerated membrane durability test applies real-world transit bus conditions with an enhanced level of stress that ensure premature formation of membrane fractures. This includes relative humidity cycling, and elevated voltage, temperature and oxygen concentration. Preliminary results show good consistency with failures observed in bus field trials such as formation of gas leaks, divots, deposition of platinum in the membrane (PITM), and membrane thinning.

Says SFU project lead Erik Kjeang: “Our strong multidisciplinary collaboration between chemistry and mechatronic systems engineering (MSE) is bearing fruit. The fuel cell is a mechatronic device, and the bandwidth of this project allows advances in chemistry to be engineered and implemented into Ballard’s products.”

Adds Ballard lead Shanna Knights: “We are pleased with the progress that our multidisciplinary team from SFU and UVic is making to develop improved membrane lifetimes for our next-generation fuel cell bus module and to understand the details of these complex failure mechanisms.”

“With continued work, this research will permit significant product costs savings and improved fuel cell lifetimes so we can directly compete against incumbent diesel technology.”

The research team, comprising 40 highly qualified personnel—graduate students, undergraduate co-op students and post-doctoral fellows—is also developing simulation tools that can eventually be used by industry partners in their testing protocols and operations of fuel cell buses.

SFU post-doctoral fellow Amir Niroumand, who heads the research on system level reliability and lifetime for fuel cell buses, says their objective is to operate fuel cells safely with extended lifetimes by studying how and why these fuel cells work.

“Our algorithms can be used for repair and maintenance, following through something like the check engine light in the car,” explains Niroumand. “When onboard diagnostics indicate maintenance is required, the check engine light goes on and tells you to take the car to the shop; however, the car would not stop and would continue to operate. This requires the capability to detect potential issues and determine operating capabilities.”