An oil rig in Niigata Prefecture, Japan. (Credit: Flickr @ tsuda http://www.flickr.com/photos/tsuda/)

An oil rig in Niigata Prefecture, Japan. (Credit: Flickr @ tsuda http://www.flickr.com/photos/tsuda/)

Two new research projects are receiving funding from the Research Council of Norway to develop nanoparticles that can dislodge leftover oil that remains trapped in reservoirs after conventional recovery has been completed.

Every percentage point of enhanced oil recovery rate represents billions in revenues.

“Nanotechnology is a generic technology with the potential for a wide variety of industrial applications,” says Aase Marie Hundere, Special Adviser at the Research Council and part of the NANO2021 program secretariat. “The petroleum industry is Norway’s largest, with vast international potential. Collaboration with the PETROMAKS 2 program provides an excellent opportunity to attract projects that involve specific users from industry.”

One of the projects awarded funding is hosted by the research foundation SINTEF, while the other will be hosted by the Norwegian University of Science and Technology (NTNU). Both projects have secured petroleum companies as partners. Together the projects will receive a total of nearly NOK 14 million ($2.27 million) from the Research Council for the period 2014–2017.

Plugging errant water paths with gel

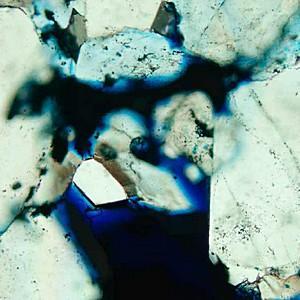

Microscope image of reservoir rock. The rock pores (shown in blue) may contain trapped oil, gas and water. Nanoparticles can be used to recover more of the residual oil. (Credit: Ingrid Anne Munz)

One of the problems with reservoirs that have been producing petroleum for an extended period is that the water injected flushes less and less oil out. Eventually the injected water is wasted, flowing through the same water-saturated zones rather than being diverted through new areas still containing mobile oil.

SINTEF Petroleum Research is heading a project to develop chemical systems that can seal off these zones by sending a solution of nanoparticles and polymers down into the reservoir to the areas where the operator wants to prevent water from flowing. Once they are in position the particles, together with the polymers, will form a gelatinous structure (a gel) that prevents water from flowing through.

It may take the particles weeks or months to make their way through the reservoir, so the project researchers will have to figure out how to keep the gel from forming before the particles have reached their intended destination.

Another critical point will be to discover how the particles are transported through the porous rock: Will they slip through easily to their destination or get caught up in the pore walls along the way?

Together with NTNU, the University of Kansas and a number of petroleum companies, SINTEF will investigate two alternative solutions. Both are based on silica nanoparticles whose surface has been engineered to bind polymers together and form a gel. Developed by SINTEF Materials and Chemistry, the nanoparticles are similar to those used in certain products by Norwegian paint producer Jotun and in other products.

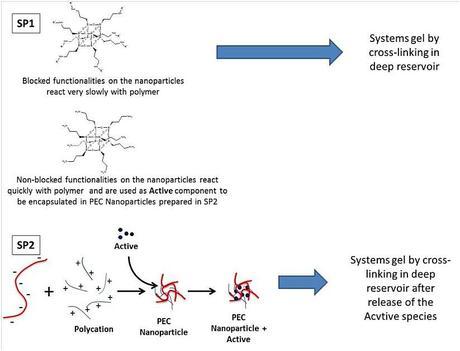

In the first alternative, chemicals will be used to deactivate the surface of the nanoparticles—keeping them passive for weeks or even months—before being activated to bind the polymers together at their destination point.

In the second alternative, active nanoparticles will be packaged into larger nanoparticles that transport them to the point where they are to be released in order to form the gel. The smaller particles will be produced by SINTEF. The University of Kansas has developed the transport particles and is already testing them in field experiments at North American oil reservoirs.

Project manager Torleif Holt of SINTEF Petroleum Research sees great potential for the technology, if successful.

“In the course of our three-and-a-half-year project period, we hope to have learned enough to know whether this method is viable,” he explains. “We would then able to estimate the quantities of nanoparticles needed and have some idea about when this is a financially feasible option.”

Functionalized particles to speed up oil flow

Two alternative ways to apply nanoparticles. (Credit: SINTEF). Click to enlarge.

While the SINTEF project focuses on plugging holes, the NTNU-led project is looking to speed up the flow of oil. Much of a reservoir’s leftover oil remains trapped in small rock pores. NTNU researchers will be customizing nanoparticles that can help to dislodge this oil and dramatically increase the amount of oil that can be recovered.

One method will utilize “Janus particles”, which feature a special surface of two different hemispheres: one is hydrophilic (attracted to water), the other hydrophobic (attracted to oil). Down in the reservoir, where both oil and water are found, the nanoparticles will spin like wheels and push the oil forward.

“This is an early-stage project,” says project manager Jianying He, an associate professor at the NTNU Nanomechanical Lab. “But the idea is very exciting and has major potential for raising the recovery rate of Norwegian oil.”

The petroleum companies Det norske and Wintershall are signed on as partners, and project researchers will be communicating with Statoil as well. The University of Houston is the research partner.

The second method involves changing the surface charge of nanoparticles to make them capable of slipping between a reservoir’s oil and rock.

If development proceeds as planned, Professor He estimates that the nanoparticles will be on the market in roughly seven years. She sees two challenges to using nanoparticles for enhanced recovery: HSE and production capacity. HSE should not be problematic in this case, as studies show that silica-based particles are not hazardous to the environment.

Production capacity, however, may prove to be an obstacle to large-scale utilization of nanoparticles. Petroleum companies would need millions of tonnes of nanoparticles daily. Currently there is no facility that can produce such quantities.