My vintage miniature sewing machine: Essex MK1, more than a toy | #LRCrafts - DIY Passion: if you can think it, you can make it

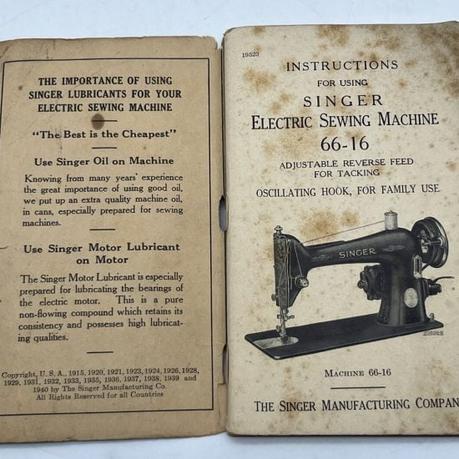

Ever since I got my first vintage Singer and published my Singer serial number database, I’ve fallen deeper into the world of vintage sewing machines. What started as a fascination, born out of childhood memories, quickly turned into what I could only call an addiction! As I kept researching, I discovered an entirely new category of machines I had never explored before: toy sewing machines.

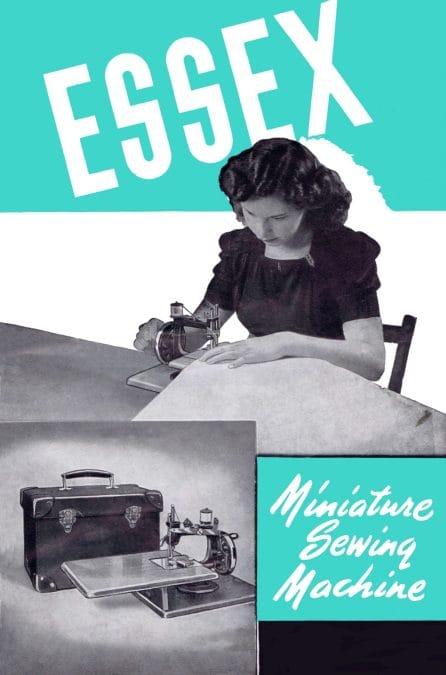

Despite their denomination, these charming little machines weren’t always just toys. Many were marketed as fully functional sewing machines, not only for children but also for adults. They could be suitable for beginners looking for an easy-to-use machine, or for sewists who needed something compact and portable. Advertisements often included claims like “Not a toy, but a real working machine”, just for additional clarity. Well, I was hooked!

And now, you know what? I finally own one! Let me introduce you to my latest vintage find: my Essex MK1.

Follow along as I share the unexpected way I came across this machine, the history behind toy sewing machines, and the process of cleaning, restoring, and putting it back to work.

Table of contents

About Essex Engineering

The company behind this toy sewing machie, Essex Engineering, was originally a small repair shop founded in 1935 by Horace Kenneth Victor Allen. They specialized in fixing “one-armed bandits” (or mechanical gambling machines). During WWII, they turned to producing parts for guns and precision gauges. But once peace returned and sewing machines were once again in short supply, the company saw an opportunity. Inspired by a toy machine from America, they began producing a small, affordable alternative for home sewing: the Essex MK1.

Manufacturing continued until 1956, when Essex Engineering Works introduced a second version of the machine: the Essex Miniature Model II. With department stores asking for a more modern-looking design to match the times, the company retooled and cast an updated version at considerable expense. The Model II retained the same chain-stitch functionality as the previous MK1, but featured a sleeker look to suit the changing tastes of the era. It was an instant success, but unfortunately it didn’t last long: soon, global competition brought the line to an end. Japanese manufacturers, supported by post-war American investment, began flooding the market with sleek, subsidized machines. At the same time, the spirit of the age was shifting: sewing suddenly stopped being an interest for young girls.

Though production stopped, Essex Engineering never disappeared. The company lives on to this day, still run by the Allen family and employing around 35 people: a family business just like it did back then. They’ve long since moved from sewing machines to high-precision coin mechanisms, used in everything from pub pool tables to laundromats, with over 1.2 million mechanisms made and exported worldwide.

The Essex MK1

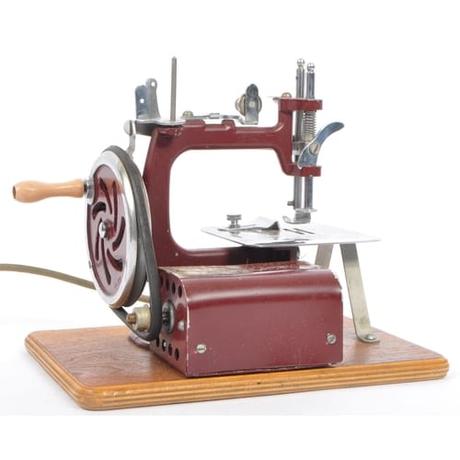

The Essex MK1 is what collectors call a Singer clone: it’s specifically a reinterpretation of the Singer Model 20 from the 1910s.

Introduced in 1946, shortly after Singer’s patent on their popular miniature 1910 Model 20 expired, the Essex MK1 was Essex Engineering’s answer to the post-war sewing machine shortage. They reverse-engineered the Singer model, added a few thoughtful improvements, and launched the MK1.

While often seen as a toy, this little machine was designed to sew as a proper sewing machine. The MK1 indeed became popular both as a toy and as an alternative to a bigger machine. This was mainly because of a great shortage of full-sized sewing machines during the rationing years after WWII. However, at the time, it wasn’t much cheaper than a full-sized machine: one Essex MK1 would cost about a week’s wage, the equivalent of around £430 today.

One of its most charming features (my favourite) is the exposed mechanism, reminiscent of the elegant pre-war Singer 20 models. Unlike the post-war Singer Sew Handy with its enclosed design, the MK1 lets you see its inner workings in motion: a detail I absolutely love.

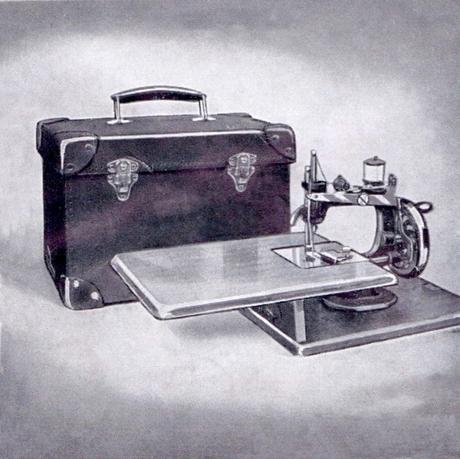

It’s also small and light, weighing just 1.45 kg (3.2 lb). It usually came with a table clamp to keep it stable during use. It usually had as well as a wooden extension bed to support fabric during stitching. One of the thoughtful improvements over the Singer 20 was also the additional wooden table base the machine is bolted tow, which provides extra stability and includes support under the stitch plate: a real help during sewing.

Every Essex MK1 was painted in a deep maroon, a finish that’s both distinctive and delicate, even though much more prone to chipping than the more durable black paint on the Singer machines. Still, many examples survive in remarkably good shape. Mine, for instance, is complete with its clamp, base, and table extension. Most importantly, the mechanism runs beautifully, even better after a bit of cleaning and oiling.

Production of the MK1 continued until 1956, when it was succeeded by the sleeker Essex Miniature Model II. Toward the end of its run, the MK1 could even be fitted with an optional electric motor.

Sadly, there are no casting marks to precisely date each unit, as we are used to with Singer serial numbers, so all we can say for certain is that any Essex MK1 was made sometime between 1946 and 1956.

About my toy machine

The unboxing

The package arrived early in the morning. I was home alone, with less than an hour before I had to start work: just enough time to enjoy the moment. No way I could wait! I grabbed my phone and hit record, filming my unboxing just like those influencers do, to revisit the moment and also to share it with family, friends and YouTube viewers. And wow!

The machine was exactly as in the listing, maybe even better! The paint was almost perfect, impressive for one of the most delicate features of this model. The metal was dirty but not rusty, with only the original needle showing signs of corrosion. The wooden base was nearly pristine. The original cardboard box was included too.

That smelled awful! Clearly, it had been stored in a damp place for a long time, with visible traces of moisture damage. But the box still had its branded packing tape and a printed design just like the cover of the Essex manuals I had seen online: below, a photo of the machine with its accessories; above, a woman sewing with it.

I gently took the machine out. Carefully, I reached for the handwheel and gave it the lightest turn. It moved!

I didn’t dare turn it too much, not before checking everything thoroughly and oiling any moving part. But at that moment, I knew: this little machine had made it through the years in amazing shape. I’d been lucky, indeed!

Welcome home, Essex MK1!

The cleaning and oiling

Before anything else, I gave the machine a good, long cleaning. I started gently, just using a soft cotton cloth, honestly a bit nervous about unmounting anything at first. I was afraid I might not be able to put it back together again!

So the first round was just a general surface clean, removing dust from every visible spot. It didn’t take long to notice the transformation. The rich maroon started to shine through again, and it was clear the machine had gone undusted for a long while.

One detail caught my eye in particular: the area beneath the seam guide. When I removed it, I discovered the surface underneath was smooth and shiny, much more so than the surrounding metal. It was clear that this part had never been taken off before, and that it had protected the paint for years. The contrast in sheen was striking, revealing just how much dust and oxidation had settled on the exposed parts over time.

Cleaning became more than just a practical task: it was the perfect way to learn how the machine was built. As I worked, I got familiar with each part, what moved, where oil would be needed, and how everything interacted. It felt like the right way to get to know this machine, piece by piece.

Eventually, I got brave enough to remove some parts. I started small, taking off screws and fittings I felt confident I could replace. I even experimented a little: for one underside piece, I tried using a light metal sandpaper my father once gave me. Since it was the back side, I wasn’t too worried about making a mistake. The results were encouraging: it brought back a gentle shine without scratching the surface.

I also sanded some of the screws themselves, and it made a big difference visually. Once one part I removed was clean and polished, I put it back where it belonged, taking care to align pieces properly and screw them in gently.

There was one small mishap: I accidentally broke the needle. I had planned on replacing it anyway, since it was super rusty, but I was still a bit sad to see it go. From then on, I took extra care with every step.

Despite the broken needle, the whole process was deeply rewarding. The Essex MK1 was quickly starting to look like itself again: shiny, clean, and full of character.

And then my husband came to help. He was confident enough to unscrew pieces I hadn’t dared to touch.

The trickiest part turned out to be removing the broken needle: it was well and truly stuck, rusty and resistant. He tried to pull it out at first, but quickly stopped, worried he might damage the needle bar. In the end, he applied a bit of lubricant, and only then was he able to ease it out without forcing it.

Next, he detached the machine from its wooden base, unscrewing both the base and the metal supports holding the stitch plate in place. Without the base, the machine felt noticeably more unstable: suddenly the design improvement made by adding that lower table felt even more significant.

He also removed the stitch plate entirely so he could clean it thoroughly, front and back. With the plate off, the chain stitch mechanism was fully exposed and we could finally watch it in action. It was mesmerizing, and I couldn’t wait to see it work with thread! But that part, too, needed cleaning before anything else.

Once everything was dust-free and polished, we carefully oiled all the moving metal parts with sewing machine oil. What a difference that made! Everything started to move smoothly and silently.

After a final pass of cleaning and some adjustment to the tension regulator, it was time to fit a new needle. We mounted the machine back onto its base… and just like that, it was ready to sew.

How to thread (and a little sewing test)

The threading of my Essex MK1 miniature sewing machine, step 1

The threading of my Essex MK1 miniature sewing machine, step 2

The threading of my Essex MK1 miniature sewing machine, step 3

The threading of my Essex MK1 miniature sewing machine, step 4

The threading of my Essex MK1 miniature sewing machine, step 5

The threading of my Essex MK1 miniature sewing machine, step 6

The threading of my Essex MK1 miniature sewing machine, step 7

Threading the Essex MK1 is easy, but getting it right makes all the difference in how smoothly the machine runs. I’ve recorded a short video walking you through the threading steps on my own machine, if you’d like to follow along. For reference, I also recommend checking out the threading diagram and photo guide provided by SingerSewingInfo, which I found very helpful.

In short, you begin with the needle in its fully raised position and pass the thread through the aligned holes in the spool support bracket and rocker arm. From there, it travels across the top arm of the machine and down through the tension system at the back, slipping between the tension discs before heading back up to the needlebar. Then it’s guided through the hole in the rocker arm and finally threaded from left to right through the needle itself.

It’s essential to use a proper 15×1 needle, and (this is key) pull the thread through the center of the presser foot and out the back, under the foot. Also, when you begin sewing, maintain a slight pull on the thread tail until the first few stitches are complete. Skipping these last two steps is a common cause of frustration and skipped stitches, so don’t overlook them!

With the machine fully cleaned, oiled, and threaded, we were ready for a little sewing test. I grabbed a small piece of fabric to try out a few stitches, curious to see the Essex MK1 in action. And it didn’t disappoint! The machine produced a lovely, neat chain stitch right away. I cut the thread and flipped the fabric to admire both sides: the front showed regular stitching, while the back revealed that distinctive looped chain.

Chain stitch is ideal for basting, since you can simply pull the end of the thread and the entire seam will come undone in seconds. To secure it instead, you just need to pull the thread out of the final loop, like finishing a crochet chain, so it won’t unravel.

I was quite pleased with the result. In fact, I’m even considering using this delicate chain stitch as a decorative element in future sewing projects.

What next?

This little Essex Mk1 has been such a fun project, from its dusty unboxing to that first satisfying line of stitches. I’m honestly impressed by how well it sews, and I’ve really enjoyed getting to know this tiny but mighty machine.

What do you think? Would you like to see a real sewing project made with the Essex Mk1? Or maybe more deep dives into other vintage toy sewing machines? I’d love to hear from you: drop a comment and let me know what you’d like to see next!

More on our vintage sewing machines

My vintage miniature sewing machine: Essex MK1, more than a toy

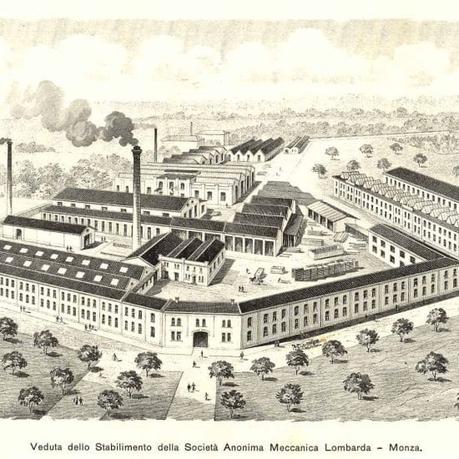

The sewing machines produced in the Singer factory in Monza (Italy)

Singer 31K15 industrial sewing machine looking for a new home

Manuals for vintage Singer sewing machines

by Rici86.