Ensure the safety and performance of your vehicle by inspecting the rear wheel bearings. Learn how to properly inspect and maintain them with this guide.

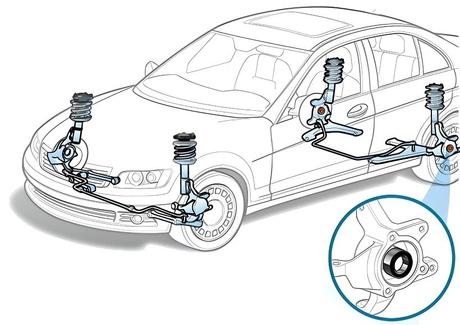

Inspecting rear wheel bearings is an essential part of vehicle maintenance, especially if you notice any signs of potential issues. Rear wheel bearings are critical components that support the weight of the vehicle and allow the wheels to rotate smoothly. Here's a step-by-step guide on how to inspect rear wheel bearings:

Tools Required:

1. Jack and jack stands or a vehicle lift2. Lug wrench or socket set

3. Screwdrivers

4. Pliers

5. Wheel bearing grease (if repacking is necessary)

6. Clean rags or shop towels

Step-by-Step Inspection:

1. Prepare the vehicle: Park the vehicle on a level surface and engage the parking brake. If you're using a jack, lift the rear of the vehicle and secure it on jack stands.2. Remove the wheel: Use the lug wrench or socket set to loosen the lug nuts but do not remove them completely yet. Lift the vehicle high enough to remove the wheel and tire.

3. Check for play: Grasp the top and bottom of the tire and try to rock it back and forth. If there is any noticeable play or movement, it could indicate a worn-out wheel bearing.

4. Check for noise: While the wheel is off the ground, spin it by hand. Listen for any unusual noises such as grinding, humming, or rumbling. These noises can also indicate a problem with the wheel bearings.

5. Inspect the seals and grease: Look for signs of leaking grease around the wheel hub or behind the brake assembly. Damaged or worn-out seals can lead to dirt and water entering the bearing, causing premature failure.

6. Check for roughness: Rotate the wheel slowly and pay attention to any roughness or resistance. A rough feeling during rotation can suggest a damaged or worn-out bearing.

7. Perform lateral play check: Hold the tire at the 3 o'clock and 9 o'clock positions and try to move it in and out. Any noticeable movement can indicate an issue with the rear wheel bearings.

8. Inspect ABS sensor (if applicable): Some modern vehicles have ABS sensors integrated into the wheel bearing assembly. Ensure the sensor is securely mounted and undamaged.

Repacking Wheel Bearings (if necessary):

If you have serviceable wheel bearings that require repacking, follow these additional steps:1. Remove the wheel hub assembly: This process can vary depending on the vehicle make and model. In general, you'll need to remove the brake caliper, rotor, and any other components in the way to access the wheel bearing assembly.

2. Clean the bearings: Use a suitable solvent to clean the old grease and dirt from the bearings. Be gentle and avoid damaging the bearing surfaces.

3. Inspect the bearings: Check for signs of wear, pitting, or discoloration. If you notice any significant damage, it's best to replace the bearings.

4. Repack with grease: Apply a suitable wheel bearing grease to the bearing rollers or balls. Make sure to distribute the grease evenly throughout the bearing.

5. Reassemble: Put the cleaned or new bearings back into the hub assembly, reassemble all the components, and tighten everything according to the manufacturer's specifications.

6. Perform final inspection: Before reinstalling the wheel, recheck for any play, roughness, or noise in the wheel bearing.

Remember, if you are unsure about performing this inspection yourself, it's always best to consult a qualified mechanic or take your vehicle to an automotive service center for a professional inspection. Properly functioning wheel bearings are crucial for the safe operation of your vehicle, so any signs of damage or wear should be addressed promptly.