I sewed myself a bag for my travel embroidery projects (+ pattern) | #LRCrafts - DIY Passion: if you can think it, you can make it

I love embroiderying on the go. During the commute to work, while on lunch break, on vacation, I love having my hands busy creating something with needle and thread. In the latest years, my go-to travel projects have been German brick stitch embroideries, such as my Medieval purse or the most recent needle roll.

While at the beach last Summer, I always had my current embroidery project to work on while my child was playing with the other children around. I had a bag I got from a store, the perfect size to host the frame and a tiny purse with the basics (needle, thread, scissors). The problem was that, when I put things inside the beach bag, the purse slipped out easily, since the shopping bag had no zipper or button to close it. Also, it had no shoulder strap, so taking it with me while following my child wasn’t comfortable.

As soon as we came back home, I browsed my fabric stash to find material to make me a proper embroidery project bag. And I got just the perfect fabric! Here I show you my concept, the pattern I designed and how I sewed a bag to fit my needs.

Embroidery and sewingLucet

Click for the finished project detailed photos

Table of contents

Want a free pattern?

If you like my bag project and want to make one yourself, you can download a quick pattern to print, ready to cut and sew.

Complete with the QR code and URL of this post you are reading just now.

Choosing the fabric

As for the fabric selection, I found a striped piece in my stash that I absolutely loved. It was leftover from a tunic I made for the Live Nativity Reenactment in Zavattarello, and I’d been saving it for just the right project. This fabric was perfect for the bag because of its peculiar qualities. The weave is reversible, meaning both sides look identical, which allowed me to skip the lining entirely. This was a big win for me because skipping the lining not only made the construction process simpler and faster, but it also kept the bag lightweight and thin—ideal for a project bag that I could easily carry around.

Since the fabric had a good amount of structure on its own, it didn’t need any extra reinforcement. That made it compact but still strong enough to hold my embroidery frame, threads and basic tools without feeling flimsy. Another bonus was the fringed selvedge, which I decided to use as a decorative element. I love when functional parts also add a bit of charm, and this gave the bag a handmade, yet polished look. Also, I could avoid stitching a couple of hems.

If you want to copy this bag project, and don’t want to add a lining, I advise you to choose a fabric with the same characteristics as mine: it should be good-looking on both sides, sturdy and structured.

What you need

- Fabric of your choice (more about the measures later on)

- Elastic band

- Zipper

- Scissors

- Thread matching the fabric color

- Sewing machine (optional, but advised) or needle

Cutting the fabric

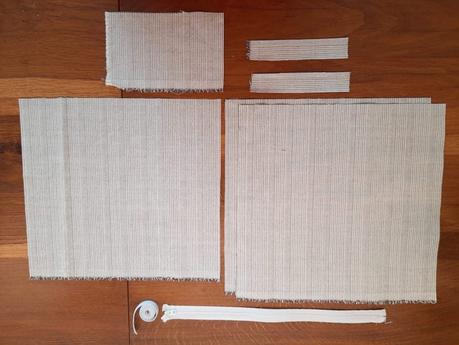

To begin, the first step is cutting your fabric. You will need:

- 2 main panels (mine are 35×35 cm – that is 14×14 in)

- 1 inner panel (same width as the main panels, but shorter in height – mine is 35×32 cm, or 14×12 1/2 in)

- 1 inner pocket (mine is 20×13 cm, or 8×5 in)

- 2 small rectangles for the strap rings (mine are 8×4 cm, or 3×1.5 in)

Additionally, you’ll need a strip of elastic as wide as the main panel (in my case, 35 cm or 14 in). I chose a 2 cm (1 in) wide elastic. The zipper should be slightly longer than the width of the main panels.

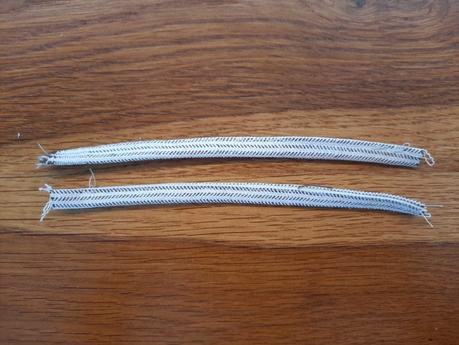

Making the strap rings

First thing I did was making the strap rings. I wanted them in the same fabric I chose for the bag, sewed in the construction to be solid and resistant. You could also choose another fabric, even leather, or sew metal rings instead.

I followed the same process you’d use to make bias tape, if you’re familiar with it. The difference is I cut my fabric along the cross grain, because I didn’t want the rings to be stretchy. Also, that meant having them follow the same striped pattern of the finished bag.

I cut my two strips of fabric and folded them in half along the long side. After folding, I pressed, then folded in half again and pressed. Then I sewed to keep the fabric closed, stitching as close as possible to the fabric edge. If you decide to sew by hand, you could use an invisible stitch, but I really didn’t mind using my sewing machine. It was quick, it made the seams really strong and long-lasting, and the sewing thread literally disappeared in the fabric pattern and weave.

Attaching the zipper (side one)

Now for the zipper, which can be intimidating at first. If you break it down into small steps, though, it becomes easily manageable.

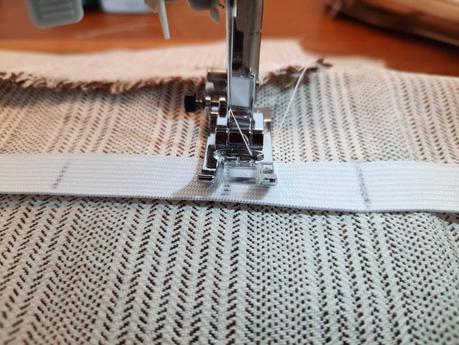

Place your first main panel on the table with the right side facing up (this is the side you want on the outside of the finished bag). Then, take your zipper and lay it face down on the fabric, aligning the top edge of the fabric with the zipper tape edge. Pin them together.

This is where I used the fringed selvedge of my fabric as a hem. The fringe will peek inside the bag, adding a nice decorative touch. Using the selvedge also reduces bulk, making it easier to sew. I am used to keeping selvedge in my projects, as they did back in ancient times for mere convenience, to avoid wasting precious hand-woven fabric. Really a historybounding touch, if I may!

As you pin the zipper in place, now is the best time to add your strap rings. I learned it the hard way, and had to unstitch part of the zipper to add them later…

Position one strap ring on each side of the fabric, “burying” them between the zipper and the fabric. Align the short edge of each ring with the top edge of the fabric and the zipper. Be careful not to place the rings too close to the sides of the fabric panel. Take into account the seam allowance, as you’ll need enough room to sew the two main panels together later.

With the fabric and zipper pinned together, sew along the edge. On my sewing machine, I used my standard presser foot, but if you have one you can also use a zipper foot.

After sewing the zipper to the panel, open the seam and fold the fabric back, so that you have the right side of the fabric is facing up and the zipper is visible. Press the seam flat, then topstitch along the zipper tape to secure it and prevent the fabric from getting caught when you open and close the zipper. Sew close to the zipper teeth, but not too tight, so the zipper can still glide smoothly.

You’ll have then to repeat the same process with the second main panel, but first you need to address the inside features of the bag.

The inner additions to the bag

Attaching the inner pocket

If you sew the zipper to one of the main panels first, you’ll have a better sense of where the zipper sits, which will help you decide on the perfect spot for the inner pocket.

For the pocket, I once again used the decorative selvedge for the top edge as a natural hem. If you’d like to do the same, fold the other three edges (sides and bottom) to the inside, press them, pin in place, and sew along these edges to create neat hems. If you don’t use the selvedge, be sure to hem the top edge as well.

Now, take the main panel with the zipper already sewn in, and flip it so the wrong side is facing up. This is the inside of your finished bag. Decide where you’d like to place the pocket. I positioned my pocket 10 cm (or 4 in) from the top edge, allowing enough room for the elastic band.

To center the pocket horizontally, align one edge with the side of the main panel. Measure the distance from the other side of the pocket to the opposite edge, divide by two: you’ll have the correct measurement for both sides, to ensure it’s centered.

Before sewing, I suggest you to place the elastic band above the pocket, to check that there’s enough space for both to sit comfortably.

Once you’re happy with the position, pin the pocket in place. Then, sew along the right, left, and bottom edges, stitching close to the edge to secure it.

Adding the elastic band

The elastic band will hold your floss bobbins or tools. Pin it horizontally above the pocket, leaving enough space between it and the zipper. Using chalk or a pencil, trace vertical lines where you want to create compartments. To store my floss bobbins, I used one as a guide. I made alternating compartment sizes: one small, matching the shorter side of a bobbin, then one larger matching the longer side, and so on.

You can baste the dividers in place and test them before sewing them down. I recommend using a sewing machine for extra strength. Start and finish your stitching just outside the elastic, onto the fabric, to secure it well.

Remember, the bag won’t have a lining, so these stitches for the pocket and elastic will be visible on the outside. In my case, the stitches blended into the fabric, but I suggest testing on a scrap of fabric first. If you’d like to hide the exterior stitches, consider adding decorative patches or embroidery before fully assembling the bag. Adding decorations after the inner panel is sewn in can be tricky.

Sewing the inner panel

Once the pocket and elastic are finished, it’s time to sew the inner panel, which will divide your bag into two compartments.

Lay the main panel you just worked on flat on your table, inner side up. Place the inner panel on top, aligning the bottom and side edges. Pin in place and sew along the sides and bottom.

Keep your stitches close to the edge, so they disappear into the seam allowance when you attach the final panel.

Attaching the zipper (side two)

Now it’s time to attach the zipper to the other main panel. You’ll repeat the same process as before.

Pin the other side of the zipper to the top edge of the second panel, right sides together. Once pinned, you can check if the construction is correct by “closing” the zipper: flip the fabric to simulate the closed bag. Make sure the zipper aligns and that the inner sides of your bag are in the correct place.

Remember to insert the strap rings just like before, making sure they form neat loops bridging across the zipper.

Once you’re confident everything is aligned, sew along the edge, flip the fabric to the right side, press the seam, and then topstitch along the zipper for a clean finish. At this point, both main panels should be attached to the zipper.

Final construction: sewing the main panels together

Now we’re onto the final and easiest part of the project: sewing the main panels together.

With the zipper now attaching both main panels, align them with their inner sides touching. Check that the zipper is properly aligned and closes smoothly. Don’t close the zipper completely before stitching, or you’ll had a hard time opening the finished bag.

Pin the sides and bottom of the panels together. As you sew along these edges, the seams should hide the previous stitches from attaching the inner panel inside the seam allowance.

Let the ends of the zipper sit neatly outside the panels: in the end they’ll stay inside your finished bag.

My fabric was prone to fraying, so I finished the raw edges with a strip of bias tape to secure the seam allowance. You have a few other options for finishing the seams:

- Use a serger or a zigzag stitch on your sewing machine.

- Flat-fell seams, as they did back in the 19th century.

- Turn the edges of the fabric panels before stitching them together.

- Leave the edges raw if your fabric doesn’t fray or if you prefer a more relaxed finish.

Choose the option that best suits your fabric and preference.

Once the final stitches are done, turn your bag right-side out, and your project is complete!

The removable strap

For the removable strap, I could have gone with a pre-made option, either bought or “borrowed” from an old bag. However, I decided to create my own using my favorite tool: the lucet fork.

I had recently discovered a new technique that allowed me to make a flat, thin band with four strands of yarn instead of the usual single-strand cord. This method produces a sturdier, more decorative strap, perfect for my project.

I picked four colors that matched the bag, made the strap and sewed a carabiner at each end for easy attachment. I wanted my custom bag to be fully handmade, and this was the perfect opportunity to test my lucet flat cord skills. A regular thin cord with a square section, made with a single strand, would have been too weak to support the bag’s weight, so this was the perfect solution.

Conclusion

I’m absolutely thrilled with how my embroidery project bag turned out! It’s lightweight, compact, yet surprisingly spacious—perfect for carrying my WIP embroidery projects wherever I go, whether it’s during my commute, on vacation, or while running errands. The bag comfortably holds all the essentials I need, from floss bobbins to scissors, and even works well for my lucet WIP projects. Stay tuned to know more about the crafts I’ll make while on the go with my new bag!

If you decide to give this project a try, I’d love to hear about your experience. Feel free to share your thoughts or questions in the comments, and if you’ve made your own version, please let me know how it went!

by Rici86.