HVAC units are lifesavers. They help us attain desired airflow, temperature, humidity, and other such conditions. For example, in the pharmaceutical industry, some medicines need controlled environments for you to create them. Likewise, it becomes a vital component in many other sectors as well.

According to GrandViewSearch – The global cooling towers market was valued at USD 3.53 billion in 2020 and is expected to expand at a compound annual growth rate (CAGR) of 4.1% from 2021 to 2028. The increasing demand for energy-efficient cooling systems in commercial and industrial applications is expected to drive market growth over the forecast period. Read full.

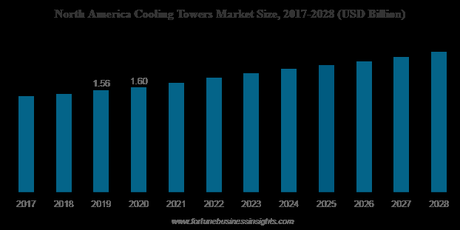

North America Cooling Towers Market Size, 2017-2028 (USD Billion)

One of the primary elements of an industrial HVAC system is the industrial cooling towers. They are responsible for the heat transfer operation. Using water and other chemicals, these cooling towers reduce the heat of the air/fluid.

Industrial Cooling Tower Best Practices

In this blog, we will help you understand some of the best practices to perform cooling tower cleaning and maintenance. The cooling towers referred to in this article are not the huge concrete ones seen in power plants. These are steel cooling towers that are much smaller.

1. Regularly inspect the towers

In many cases, the poor maintenance of cooling towers is what leads to problems that cost you a fortune. Hence, you must regularly take a look at the cooling towers with the help of an expert.

Include inspecting the towers for sediments, scales, and buildup as a part of your employees’ daily routine. It can also help with finding faults in the industrial cooling tower parts.

2. Remove scale deposits

If you don’t monitor the scale deposits, it might become a concern that only experts can take care of. The efficiency of your cooling tower gradually reduces.

Furthermore, it consumes more energy to transfer the heat. The primary reason for scale buildup is evaporation.

This process is what transfers the heat from the fluid to the cooling medium. Excessive scale deposits can lead to premature deterioration of the system.

3. Maintain constant airflow

When you leave the fan off for long durations, sludge formation is inevitable. The fan’s surface also corrodes easily when unmoved for a long time. To keep your industrial cooling tower at optimal conditions, you must maintain a constant airflow.

Different industrial cooling tower types have different configurations. Hence, it is suggested to rely on custom industrial vacuum cleaners manufacturers and other equipment to remove the dirt and sludge.

4. Check for clogs

Chiller tubes make up an integral part of the cooling system. If there are any clogs in the tubes, you can witness a dramatic decrease in inefficiency.

When the water doesn’t flow properly inside the tubes, the cooling capacity of the system goes down. Leading to high energy consumption for reduced heat transfer. Hence, you must regularly clean your pipes with standard cleaning agents to remove sludge and clogs.

Getting professional cooling tower cleaning and maintenance services cover everything from inspection to thorough cleaning of the pipes. They also determine the next appropriate time for you to clean the pipes.

5. Test your water pump

Water pumps take care of pumping the water back and forth into the cooling chamber. When your pump performs well, the entire system works in a healthy state. While checking the industrial cooling tower parts, check whether the water pump works at its maximum efficiency.

By regularly cleaning your water pump, you can increase the life span of your entire unit. Moreover, you can reduce future maintenance costs by several folds.

6. Treat your water

Foreign particles in your water can cause premature corrosion/failure of the system. Schedule regular water testing to test for contaminants.

Follow industrial water treatment methods to reduce the chances of corrosion and other such damages to the pipes.

Benefits of regular maintenance

By taking care of different industrial cooling tower parts, you get to enjoy the following benefits.

1. Improves safety

Scale deposits and dirt may sound like a minor issue. However, it directly correlates to the safety of your cooling system. Excess deposits can cause heating of the system. Which may also lead to fires and other accidents in the duct.

2. Ensures health

The HVAC air ducts lead directly to the rooms. An unclean cooling system can lead to bacteria buildup. This is a health concern for your employees. Regular cleaning prevents this effectively.

3. Increases performance

The performance of the industrial cooling tower depends on the optimal working of the heat exchanger pipes. By removing the scales on these pipes, you can directly improve the performance of the cooling system and the HVAC system.

4. Saves cost

When you maintain the cooling towers at optimal condition, they do their job well. Thus, cooling a higher quantity of air in a short time. This will reduce the cost of running all the equipment.

Finally…

Always resort to expert help for cooling tower cleaning and maintenance. Most services are affordable and help you cut down future costs the smart way.