In Waiblingen near Stuttgart, the bosch engineer Istvan Denes works on a device designed to convert wave energy into electrical power. This process makes use of what are known as dielectric elastomers.(Picture: Bosch)

In Waiblingen near Stuttgart, the bosch engineer Istvan Denes works on a device designed to convert wave energy into electrical power. This process makes use of what are known as dielectric elastomers.(Picture: Bosch)A research network made up of four companies and two universities aims to establish sustainable power generation along the world’s coastlines. Until January 2015, the German Federal Ministry of Education and Research is supporting this project, known as EPoSil (electroactive polymers based on silicon for power generation), to the tune of nearly two million euros (approx. $2.65 million). This grant is part of the “smart materials for innovative products” program. In a Bosch laboratory, a first demonstrator model is already showing how wave energy can be converted into electricity.

Waves are a huge potential source of energy—29,500 terawatt-hours a year, according to calculations by the United Nations. By comparison, the International Energy Agency reports that some 21,500 terawatt-hours of electrical power were generated worldwide in 2010. EPoSil hopes to unlock this reserve of renewable energy. To quote a report on ocean energy by the UN Intergovernmental Panel on Climate Change: “Ocean energy has the potential to deliver long-term carbon emissions reductions.” This is a view shared by the German Federal Transportation Ministry is its “ocean development plan.” (You can read more about the recent ocean energy advances in our review of wave and tidal energy technologies.)

A number of expert partners have come together to exploit wave energy: Wacker Chemie AG supplies a silicon-based material. This is an essential part of the electroactive polymer that converts mechanical energy into electrical power. The project is coordinated by Bosch, together with its subcontractor Compliant Transducer Systems. The Technical University of Darmstadt is developing a method for testing the electroactive polymers. A scale model is to be tried out in the wave canal of the Technical University of Hamburg-Harburg. The systems for testing the generator units are being developed by Ingenieurbüro Brinkmeyer & Partner in Winnenden, near Stuttgart. Bosch Rexroth is supporting the consortium by constructing the models.

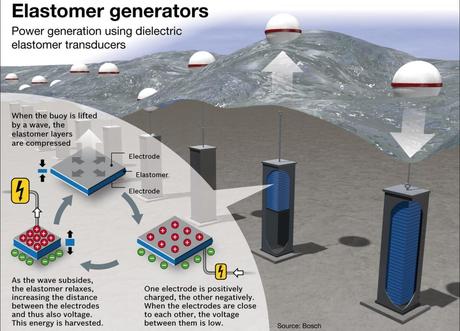

The energy converter is basically a three-ply sheet. The top and bottom layers are conductive to electricity, i.e. they are electrodes. The middle layer is made of extremely elastic silicon, which has pronounced isolating properties. Even under industrial conditions, this can be manufactured at a constant thickness.

Power generation using dielectric elastomer transducers (Picture: Bosch)

The movement of the waves exerts a mechanical force on the converter (sheet). Initially, the upward movement of the wave compresses the silicon. As a result of this compression of the middle layer, the distance between the two electrodes is reduced. A tiny electrical current is applied from an external source, positively charging one of the electrodes, and negatively charging the other. As the wave begins to fall, the force acting on the converter decreases. The silicon relaxes and returns to its original thickness. The distance between the negatively and positively charged electrodes increases. This effect leads to an increase in electrical power in the converter. The result is that the mechanical energy of the wave has been converted into electrical power. This power is harvested, and the cycle begins again.

Technically, there are several ways in which the three-ply sheets can be compressed by ocean waves. To give a simple example: imagine a buoy made up of two parts. The upper half floats on the ocean surface, the bottom half is firmly anchored to the ocean floor. The two halves are connected to each other by a stack made up of thousands of sheets. Every 3 to 10 seconds, these sheets are deformed by the movement of the waves.

“The electrical current from one individual layer is minimal, but when it is multiplied by a thousand or more, it soon adds up,” says Dr. Istvan Denes, who works for Bosch corporate research and advance engineering in Waiblingen near Stuttgart. In a next stage, an array of several converters will generate electricity. Denes uses a demonstrator model, developed by the TU Darmstadt, to show that this works in dry runs in the laboratory.

The first true-to-scale model of a wave-power generator is slated to be launched in the wave channel of the Technical University of Hamburg-Harburg in 2014. Looking further ahead, the plan is to have commercial wave-power generators compressing and relaxing again tens of millions of times. The target efficiency for converting mechanical energy into electrical power is 50 percent.