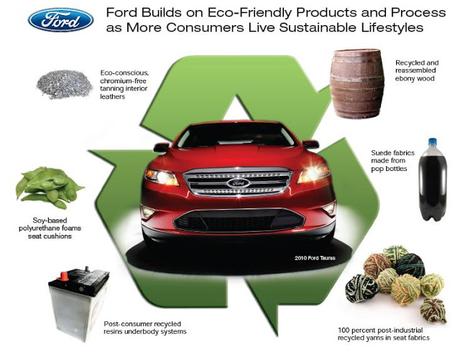

Last night I attended a really interesting dinner hosted by Ford Motor Company at Mudhen Meat and Greens located at Dallas Farmers Market. The purpose of the evening was to educate local media to Ford's ongoing commitment to sustainability. I will admit that I accepted the invitation mainly because I hadn't been to Mudhen yet and wanted to experience their cuisine. I left the dinner being super impressed by what I learned. For example, did you know Ford vehicles are currently 95% recyclable? Ford has a long history of being eco-friendly going back to the early 1940s when Henry Ford experimented with making plastic parts for automobiles. According to the Henry Ford Museum, the "Soybean Car" was a plastic-bodied car unveiled by Henry Ford on August 13, 1941 at Dearborn Days, an annual community festival. The car weighed 2000 lbs. - 1000 lbs. lighter than a steel car. The exact ingredients of the plastic panels are unknown because no record of the formula exists today. One article claims that they were made from a chemical formula that, among many other ingredients, included soybeans, wheat, hemp, flax and ramie. World War II interrupted Ford's experimentation with this program, but it didn't dampen the Ford company's commitment to a more eco-friendly way of producing their vehicles. Today, Ford uses many sustainable materials.

Here are just a few:

Tomatoes: Researchers at Ford and Heinz are investigating the use of tomato fibers in developing sustainable, composite materials for use in vehicle manufacturing. Specifically, dried tomato skins could become the wiring brackets in a Ford vehicle or the storage bin a Ford customer uses to hold coins and other small objects.

Soybeans: Ford was the first automaker in the world to demonstrate that soy-based polyols could be used at high percentage levels to make foam capable of meeting or exceeding automotive requirements. Through its use of soy foam, Ford is able to reduce its petroleum usage by 5 million pounds annually and its carbon dioxide emissions by 20 million pounds annually

Wheat Straw: Ford Motor Company, in collaboration with academic researchers and supplier A. Schulman, is the first automaker to develop and use wheat straw-reinforced plastic in the storage bins of vehicles. This will reduce petroleum usage by some 20,000 pounds per year and reduce CO2 emissions by 30,000 pounds per year.

Coconut: Ford and The Scotts Miracle-Gro Company are researching the use of coconut fiber reinforcement for molded plastic parts to reduce the use of petroleum and make the parts lighter and more natural-looking. The coconut coir, or husks, are a waste stream from Scotts’ soil and grass seed products. The team is investigating their use as a renewable material in Ford vehicles.

Dandelion Greens: Ford and Ohio State University are researching dandelions for potential use as a sustainable resource for rubber. A milky-white substance that seeps from dandelion roots is used to produce the sustainable rubber and could potentially find its way into plastic parts in Ford vehicles, including cup holders, floor mat and interior trim.

To learn more about Ford's research and commitment to using sustainable and renewable products, visit http://corporate.ford.com/microsites/sustainability-report-2015-16/products-greener-materials.html.