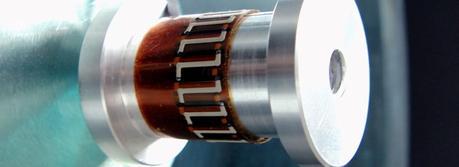

3D printing makes it possible: A demonstrator of a printed TEG wriggles flexibly around a sample component. (Source: Fraunhofer IWS)

Only a fraction of the total energy we produce is actually used for its intended purpose; the majority of the energy is wasted as useless heat. A thermoelectric generator could potentially convert that heat into electrical energy. However, such devices are difficult and quite expensive to produce. There is also a lack of suitable materials. At the Hannover trade fair a group of scientists is presenting a new manufacturing process to solve those problems. With it, generators can be cost-effectively produced in the form of large-area flexible components from non-toxic synthetic materials.

We are all familiar with them—the gigantic white clouds of steam billowing from power station cooling towers. As impressive as this spectacle may be, in reality it represents a waste of energy as large power stations only rarely manage to convert more than 40 percent of the produced energy into electrical power. The rest is released unused, mainly via the cooling towers, into the atmosphere. Researchers have been working on utilizing the potential lying dormant in the over 150 m high concrete giants. The magic formula for this is known as thermoelectrics. This area of physics is concerned with generating electricity from temperature differences, and it is precisely in cooling towers where there can be very large differences between the hot steam and cooler concrete skin under some circumstances.

The scientists‘ vision is described by Dr. Aljoscha Roch of the Fraunhofer Institute for Material and Beam Technology IWS in Dresden: ”Thermoelectric generators (TEG) currently have an efficiency of around eight percent. That sounds very small. But if we succeed in producing TEG cost-effectively, on a large scale and from flexible materials we can install them extensively on the insides of the concave cooling tower wall. In this way, through the enormous amount of energy produced in the huge plants—around 1500 liters of water evaporate per minute—we could generate large quantities of electricity”.

Together with his colleagues at the IWS, Roch has now taken a big step closer to this goal. The scientists have succeeded in producing TEG by means of a printing process. The miniaturized generators can not only be produced cost-effectively, on large surfaces and in a flexibly manageable manner, but an additional major advantage is that the materials used are environmentally-friendly. ”TEG are today largely produced by hand from toxic components which contain lead for example. We are now using modern 3D printing technology and harmless polymers (plastics) that are electrically conductive,” explains Roch.

The new printing technology functions in a similar way to an inkjet printer. The difference is that instead of a thin jet of ink, a thermoelectrically active polymer paste emerges from the cartridge and produces the around 20 to 30 micrometer thick thermoelectric layers. “The generators have to be of a certain thickness in order to build up electrical voltage from temperature difference. Currently available 3D printing processes could be very suitable for achieving the required depth,” says Roch. The IWS researchers are demonstrating the printed TEG for the first time in a cooling tower model at the Hannover trade fair.

Minimal temperature differences are sufficient

But how is the electricity then ”harvested” from these polymer generators which are only a few micrometers in size? The hot steam activates the electrons in the generator, the negatively charged particles migrate to the cooler side and an electrical voltage is produced. Even small temperature differences such as one degree are sufficient for this effect. This has been known to physics for almost 200 years, but due to the lack of efficient manufacturing methods and suitable materials it has not been extensively utilized. The manually produced, brick-like TEG are used in space travel and in the form of tests in the automotive industry. Mounted on the exhaust pipe they supply current for the vehicle’s onboard electronics, for example. To date 600 W, the power output of around 6 light bulbs have already been demonstrated. When multiplied by the many millions of vehicles on Germany’s roads alone, several thousand million kilowatt hours could be saved by TEG.

Cars and cooling towers are, however, only two examples out of many. ”In principle waste heat is produced through the operation of every technical installation. With TEG fitted on industrial production lines, in sewerage systems, at large computer centers or on any type of exhaust air system very large and hitherto unused sources of energy could be developed,” concludes Roch.