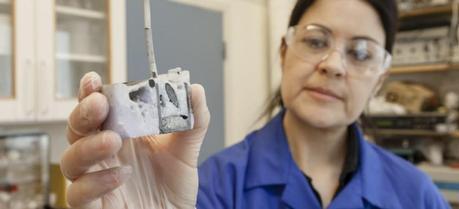

SINTEF’s Ana María Martínez believes that high-temperature electrolysis can be used to recover rare earth metals from scrap. In this photo, she has just opened a crucible used in an electrolysis experiment. (Credit: Thor Nielsen / SINTEF)

SINTEF’s Ana María Martínez believes that high-temperature electrolysis can be used to recover rare earth metals from scrap. In this photo, she has just opened a crucible used in an electrolysis experiment. (Credit: Thor Nielsen / SINTEF)

The demand for rare earth metals such as neodymium (Nd) and dysprosium (Dy) is increasing much faster than production. These metals are used in technologies such as the generators that store power in wind turbines, and the electric motors that propel electric and hybrid cars. But they are also used in everyday products like computers and mobile phones.

Rare earth metals do occur in the earth’s crust, but not in sufficiently high concentrations. This is why only one country—China—has so far been supplying the entire world with these elements. However, in recent years, China has begun to restrict its export of these materials.

Forecasts show that as early as next year, these metals will be hard to come by.

This explains why the recycling of rare earth metals from scrap is fast becoming an important research topic. Seven major European research institutes (Fraunhofer, CEA, TNO, VTT, SINTEF, Tecnalia and SP) have joined forces to invest in a joint program (Value from Waste) aimed at tackling this important issue.

“The aim is to extract valuable materials from the waste streams. The challenges lie in the fact that the material must be sufficiently clean in order to be recycled, and we have to be sure that it is not contaminated by other harmful materials”, explains Odd Løvhaugen of SINTEF ICT.

Researchers are therefore focusing much of their work on finding out which products could contain pollutants, which methods are best for analyzing and measuring the content of the polluted materials, and when such products can be expected to be found in waste.

They are also evaluating extraction methods, techniques to recycle nanoparticles in the treatment process, and how the constituents of ash can be analyzed after incineration.

SINTEF is coordinating this major EU program, which is using two groups of material technologies in the race to find good analytical and extraction methods. The approach chosen by the researchers involves a technology well-known from the aluminum and smelting industry.

In the search for sources of recycling material, many people have been considering permanent magnets. This is the most significant product to contain rare earth metals—measured both in terms of value and volume.

On the basis of tests, SINTEF researchers believe that the electrolysis technology used in aluminum plants can be used to recycle magnetic alloys from discarded magnets and scrap material from magnet manufacturers. It will take some time before there are enough scrap eco-cars to be able to recycle their motors, which is why they are turning to the magnet manufacturers for the magnetic alloys.

However, the process is still slow, and there is a lot of work still to be done before the researchers will know whether they will be able to achieve their goal. If they are successful, they will have found a method that is much simpler than alternative processes based on the use of strong acids.

Several other problems must also be solved for the stages before the electrolysis process. Among other things, there is a need for collection and disassembly methods for used magnets, and the magnets themselves must also be demagnetized locally, since the long-distance transport of intact permanent magnets is prohibited.

“Other challenges include finding methods that can identify and characterize nanoparticles in gases, water and solid materials”, says Odd Løvhaugen. “And we must create a toolbox of methods to evaluate the behavior of nanoparticles in waste treatment processes”.

In November, 2013 we reported that instead of running out of oil, the EU may soon run out of eight metals, used in low-carbon energy technologies.