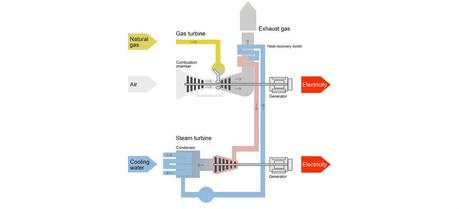

A gas and steam power plant combines the procedures of both a gas turbine and a steam power plant. The hot emissions of a gas turbine are therefore used as a heat source for a downstream water vapor circuit with a steam turbine. (Credit: E-ON)

A gas and steam power plant combines the procedures of both a gas turbine and a steam power plant. The hot emissions of a gas turbine are therefore used as a heat source for a downstream water vapor circuit with a steam turbine. (Credit: E-ON)A combined-cycle gas turbine (CCGT) in Slovakia owned by E.ON, the world’s largest investor-owned electric utility service provider, will close in the fall of 2013. E.ON says that the reasons for closure are the low electricity and carbon prices. What’s more, according to the company, the unmanaged, heavily subsidized growth of renewables and the resulting collapse of the EU emissions trading scheme are rendering in particular gas-fired power plants in Europe—which have already been hit by the recession-driven decline in power demand—largely uneconomic to operate.

The Renewable Energy Road Map sets the target of producing 20% of total EU energy consumption from renewable energy sources by 2020, as well as measures for promoting renewable energy sources in the electricity, biofuels and heating and cooling sectors. While during the first three months of 2013 green energy investment in the EU declined by 22 percent, some $40.6 billion was invested in the industry during this period.

As announced at the beginning of this year, E.ON is restructuring its conventional generation fleet in ways that will swiftly improve the fleet’s competitiveness. Alongside further cost reductions and efficiency improvements, E.ON is studying whether to close a number of its power plants in Europe and will take decisive action in cases where closing proves necessary.

In electric power generation a combined cycle is an assembly of heat engines that work in tandem from the same source of heat, converting it into mechanical energy, which in turn usually drives electrical generators. The principle is that the exhaust of one heat engine is used as the heat source for another, thus increasing the system’s overall efficiency. In an ordinary heat engine the remaining heat from combustion is mostly wasted. A CCGT plant can achieve a thermal efficiency of around 60%, in contrast to a single cycle steam power plant which is limited to efficiencies of around 35-42%.

E.ON’s Malženice CCGT, which has a gross generating capacity of 430 MW, entered service in January 2011. In the past two and a half years it has only operated for about 5,600 hours. The unit, whose fuel efficiency exceeds 58 percent, was planned to operate at least 4,000 to 5,000 hours per year.