Constant maintenance is required to keep heavy machinery which includes Construction, Industrial, Mining, or Farming equipment, in good working conditions. Heavy machinery is expensive and thus it’s necessary to maintain them often. Heavy machinery equipment can become inefficient due to poor maintenance. Machinery should be serviced to stay healthy and function normally.

In this tutorial, we’ve got some best tips for maintaining and servicing large machinery to work efficiently and durably.

#1 Train Heavy Machinery Operating Staff

Proper job-site management means proper heavy machinery handling. There are several operators working in most types of large machinery. Monitoring the correct operation of large machinery is one of the ongoing inspections that should be on your checklist. Operator training is usually done when you are purchasing the machinery. Dedicated operators are less likely to mishandle the machinery.

Skills become rusty and workers come and go, so it is necessary to keep up with the staff training. Poor operations can lead to breakdowns, which are costly. Computer simulators are used to train professional operators where machine operation, safe and efficient practices are taught and required to be followed.

It is possible to revise operator manuals for the specific work situation. Rewrite the operator manual in simple language. For easy reference, provide a short manual to each operator. Your operators will use the current version of the manual if you are operating in a paperless environment.

There are best practices you can apply to other geographic locations or other facilities, so spot these practices. The knowledge becomes quite valuable if you learn how to maintain your heavy machinery equipment. Use this base knowledge at every applicable location and leverage that knowledge.

#2 Schedule Heavy Machinery Lubrication

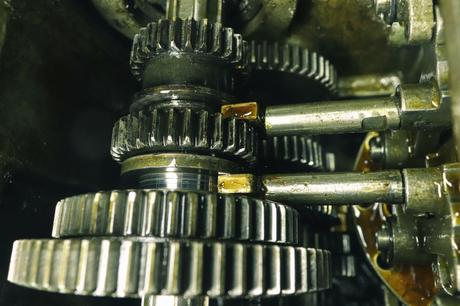

Lubricants keep heavy-duty machines running smoothly and promote asset uptime. Use lubricants on the moving parts because they reduce friction. Scheduling good lubrication maintenance increases the lifespan of the heavy machinery equipment and its parts. One of the first and the most essential of maintenance checks is lubrication. Check for signs of excess grease or oil build-up on pistons. Look for leaks around oil seals.

There are specific types of grease and oil for each machine part, so ensure you are using the right lubricant. Check the recommendations of the manufacturer. Checking the lubricants is a great method of diagnosing problems with heavy machinery. The experts analyze the particles in the used oil. And they check the composition of the contaminants to know if some parts of the machinery suffer from wear or breakdown.

#3 Search for Signs of Wear

There are many ways to spot problems in your heavy equipment. The sooner you find out these irregularities, the better. Age, friction, high temperatures, shock, and vibration contribute to the breakdown of the parts of any large machinery.

- Gears and belts that are out of alignment can cause vibration.

- Poor operator technique and accidents can cause shock.

- Poor lubrication, worn parts, friction, and extended use can result in high temperatures.

- Age can affect several key parts of the machinery. Bolts loosen and stretch out of shape. Seals dry and crack. Belts warp after some time. It is important to monitor the age of the equipment.

If you discover that a moving part of your large machinery is depreciated, replace the depreciated part as soon as possible. Purchase high-quality industrial parts and machinery and install them. This will keep other parts from malfunctioning.

#4 Keep it Clean – Hygiene your Machinery

We are not saying that your heavy machinery should be spotless at the end of the day, rather we are encouraging you to practice regular cleaning. Clean machines can run better. Heavy machinery has several seals and filters that keep the working parts of the large machinery clean and free of contamination. Ensure that the seals are in optimal condition by inspecting them regularly.

Monitor and replace the filters regularly. Keep the breathers clean to stop the breathers from sucking contaminants into the cab because it avoids the creation of a vacuum in the cab. For example, this can impact the clutch. If possible, store the large machinery in a shed or other building. Exposing the heavy machinery to weather and wind usually leads to rot and rust. If the machinery is not in use in projects, make sure it run periodically.

#5 Service and Repair Equipment Regularly

The components that you must check regularly for preventive maintenance are electrical systems, tracks, tires, and fluids. You should know what to inspect and when to inspect them. The following are some examples.

- There are lots of moving parts in power transmissions that you must keep in optimal condition. Check the gearboxes for damage to parts, vibration, and lubrication.

- Inspect the bearings, gaskets, seals, and friction materials for wear and change them. Do not rush to replace gears and shafts because they can last for a long time.

- Monitor drive train components constantly. Check v-belts and pulleys on CVT transmissions for wear and alignment. Check sprockets for breaks and correct meshing with chains.

- Change filters regularly. Detect problems by testing the oil.

- Bearings are central for the performance of heavy machinery because they keep great amounts of force running smoothly. Check lubrication on the bearings regularly. Maintain the bearings to extend their life span.

- Lubricate the gears regularly.

- Prevent bearing raceway contamination by doing a seal check.

- Bolts elongate and creep after some time, so run torque checks on the bolts.

Conclusion

These are the 5 best tips that can extend the life span of heavy machinery. They can improve the Return on Investment (ROI) from these assets. Machines need to be inspected frequently for potential problems and maintained accordingly. Heavy engineering machinery is expensive so make sure to regularly check the equipment for problems as maintenance is cheaper than breakdowns.