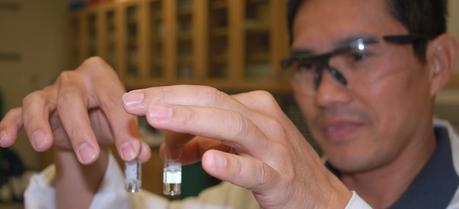

Dr. Dat Tran, U.S. Army Research Laboratory electro-chemistry, shows two samples of materials that combine to extract sulfur from JP8, or Jet Propellant 8, that is a fuel widely used in the Army. (Credit: Joyce P. Brayboy)

Dr. Dat Tran, U.S. Army Research Laboratory electro-chemistry, shows two samples of materials that combine to extract sulfur from JP8, or Jet Propellant 8, that is a fuel widely used in the Army. (Credit: Joyce P. Brayboy)A small team of scientists at the U.S. Army Research Laboratory are collaborating with counterparts at the Communications-Electronics and the Tank Automotive Research, Development and Engineering Centers, to develop technology for lightweight, portable prototype systems that would convert Jet Propellant 8, commonly referred to as JP-8, to hydrogen for fuel cell applications on the spot.

JP-8, or JP8 (for “Jet Propellant 8”) is a jet fuel, specified and used widely by the US military. It is specified by MIL-DTL-83133 and British Defence Standard 91-87, and similar to commercial aviation’s Jet-A. JP-8 is a logistical fuel for the Department of Defense under its one-fuel policy. Outside of powering aircraft, JP-8 is used as a fuel for heaters, stoves, tanks, by the U.S. military as a replacement for diesel fuel in the engines of nearly all tactical ground vehicles and electrical generators, and as a coolant in engines and some other aircraft components. The use of a single fuel greatly simplifies logistics.“There is a growing demand for portable electrical power for both commercial and military applications,” said Dr. Deryn Chu, fuel cell team leader. “Our challenge is ‘How can we remove the many impurities in JP-8 so it can be effective in a fuel cell?’”

JP-8 is widely used by the U.S. Army as a fuel for powering aircraft, engines of tactical ground vehicles and electrical generators. It comes with a set of problems like the logistics resupply chain it requires, and the high cost associated with force protection of convoys, he said.

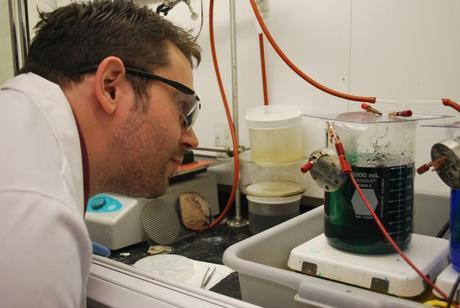

Dr. Zachary Dunbar, U.S. Army Research Laboratory electro-chemistry, is testing a way to use a rare metallic element, palladium, to purify a mix of reformate gases. (Credit: Joyce P. Brayboy)

Army units often wind up in places overseas with no infrastructure and limited supplies. The Army needs to explore and develop high-efficient fuel cell systems to reduce logistical supply. Scientists continue to grapple with the question of the best way to rid JP-8 of its organic sulfur compounds after it is in theater, Chu said.

The Pentagon’s most-used jet fuel costs roughly $15 per gallon, but “…the cost multiplies to hundreds of dollars by the time you move it to and around operational locations,” Chu said.

For the Army “…the smallest gain in efficiency is important. But fuel cells—when the concept is fully developed—may yield huge gains, potentially doubling the efficiency of diesel generators,” he said.

The chance for a game-changing technology is why fuel reformation is one of three high-risk, high-reward projects that the laboratory is pushing toward in search of operational energy solutions for the battlefield. Smart Battlefield Energy on-Demand and Long-Lived Power were also highlighted in this four-part series.

Researchers already knew the value of fuel cells for increasing efficiency, as that kind of approach has been explored since the 1960s. They also knew of ways to convert the high-energy density of hydrocarbons into hydrogen for fuel cells like the process that Bloom Energy and others use on the commercial market, said Dr. Zachary Dunbar, a team member who is exploring palladium membrane technology, using a rare metallic element as part of a purification system.

The challenge is developing a practical fuel reformation process for better energy conversion that would have to be portable, quick and easy to use, he said.

A large palladium membrane, like the one shown here, uses less than $1 worth of palladium metal, due to the ultrathin deposition processes used for its fabrication in the Army Research Laboratory Clean Room. (Credit: U.S. Army Research Laboratory)

Last year, Army Research Laboratory’s research reached a milestone when they figured out a way to reduce the production costs associated with fuel reformation by using palladium membranes to purify hydrogen rich reformate, Dunbar said.

In their work, scientists developed a new supported palladium membrane composite structure for purification technology to produce high-purity hydrogen from a feedstock of hydrocarbon fuel. Before this discovery, designing affordable, leak free, and high-flux membranes was much more difficult, he said.

“While it is a significant milestone, the research is in its early stages. Fuel reforming is a complex problem that we don’t expect to solve quickly,” Dunbar said.

The team tests materials that may reduce the sulfur concentration in JP-8. Dr. Dat Tran has tested at least 300 different combinations of materials during the last four years he has been investigating with the team, he said.

“JP-8 is a complicated and dirty fuel. The sulfur is a huge problem because it can hurt the fuel cells,” Tran said. “Sulfur has many different compounds that behave differently. The compounds in sulfur make it hard to find an agreeable material.”

JP-8 is a logistical fuel for the Department of Defense under its one-fuel policy. It is a unique problem for the Army. Industry is focused on natural gas, Chu said.

Original article by Joyce P. Brayboy.