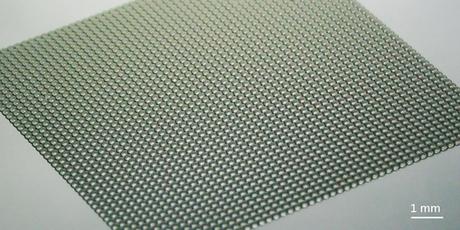

Companies that deal in diverse optical products, or devices that rely on applications of diffractive optics, often need microlens arrays. Most commoners don’t know much about micro lens, but in the world of electronic products and other industries, the use of microlens arrays is extensive. In simple words, microlens arrays can be defined as arrays of sub- millimeter lenses, which can be used for diverse requirements. You will find microlens arrays in cameras and phones to specific products that rely on sensors. Here’s more on the basics of microlens arrays.

Use and applications at a glance

In recent years, microlens arrays have been used in the world of optics in different ways. These lenses help for use of CCD arrays, as microlens arrays can collect light and focus the same on the sensitive areas for desired outputs. The application of microlens arrays also extends to the world of projectors and a wide range of devices used for imaging. For example, phones, photocopiers, and other devices like tablets do use microlens arrays, while the use of these lenses is also common for microscopes and similar products. These lenses are also required for the world of 3D imaging, and these can be manufactured as per the specific requirements of a project.

Manufacturing microlens arrays

If you own a company that relies on optics and applications of microlens arrays, you will need a manufacturer that can specialize in prototyping and designing. The production of microlens arrays is dependent on the needs of the project. For instance, some projects require two-dimensional custom microlens, while others need simple spherical lenses or aspherical ones. Many projects also rely on one-dimensional microlens, so everything is usually customized. Lenses are usually made in nickel and fused silica. The applications of one-dimensional microlens and different other microlens arrays are only expected to magnify in years to come, and if you are ordering for these optics, make sure to select a company that has advanced understanding of products and has the capabilities for productions. What matters the most is the range of configurations and requirements that they can handle, along with the costs involved.

With microlens arrays, it is possible to achieve a lot more with optics, and that’s the precise reason why more brands are spending on research. Check online to find companies that specialize in production of optics and microlens arrays to know more on the options and possibilities.