It’s almost official now that I’ll be moving home sometime within the next month. This past week, I’ve found a flat that is affordable and it’s enough for my needs. There’s still the issue over workshop contents and self storage to be encountered but, with winter only weeks away, a quiet period is often expected at this time of year. The only difference now is that I won’t be ‘awakening’ from hibernation in the spring. I can look back on 2013 as a positive year. By far, it’s been more productive than either of the last two years and my following on YouTube has increased by more than 300% – I do intend to keep my presence active on that channel but I’ll delve in to that another time.

Now, my attention turns to furnishing my next home.

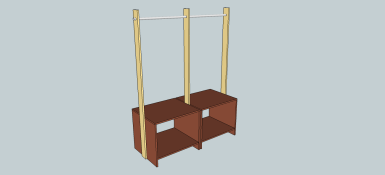

I’m quietly confident that I can find most of the items I need either through sites like Freecycle, Gumtree and Trade-It without having to pay much, if anything at all. But I’d also like to acquire some ‘flat-packable’ items in place of the larger ones. Here, I’m really thinking about a wardrobe, as there is no fitted space in this property. So, I’ve been playing around with some ideas in my head for a ‘skeletal’, minimalist design that could easily fit in the back of an estate car…

I quite like the idea of clothes being on show, as opposed to being stuffed away behind large doors that can be a pain to open within a smaller space (I rarely leave them closed in my current bedroom). My first design (at the top of this page) is probably about an simplistic as you can get. But the boxes (probably MDF or ply) would be bulky and difficult to transport on a future house move. There’s also the question of how to tie it all together and, if I did use ordinary wood screws, for how long would those holes and threads really last?

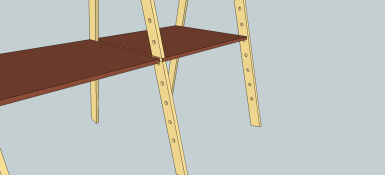

So, I did a bit of Googling for minimalist wardrobe designs and came across ideas similar to the A-frame/kid’s swing idea above. I’ve probably drawn each of these models larger than they inevitably need to be for my own use. Each frame could be made up of two parts that pivot and fold for transport, with a single pole running continuously through a hole drilled in each.

There’s then the question of fitting and fixing the shelves…

With each frame member being offset from the other, there wouldn’t be a flush side at either end of a shelf. So, even if I did use long dowels fitted in to each leg to bear the vertical load; aesthetically, it’s going to look odd with one gap and one end visible from the front or back.

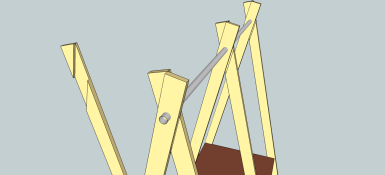

There is the thought that I could cut an acute lap joint that splices the two components together neatly and also provides that flush finish lower down. Would that be enough to hold that frame together? Would I need an additional brace lower down, to prevent the legs from splaying apart?

I’m thinking that I already know the answer to that question, as I try to contemplate how I compliment each a shelf with a brace fitted that also allows it to be adjusted and set at one of various heights.

All I really require from this is a single shelf to be able to hold my jeans and trousers. I could keep footwear underneath that but I see no dire need to suspend them from the floor (if they’re wet or dirty, they’d be better of drying or being cleaned elsewhere beforehand).

So, it’s a nervous but exciting time for me and I’ll have plenty to share as time goes on. Even without a workshop, I see this as a pretty simplistic project that could be made (assembled, really) almost anywhere with pre-machined materials and knock-down fittings.

If you would like to add any thoughts of your own then I welcome them. Thanks for reading.