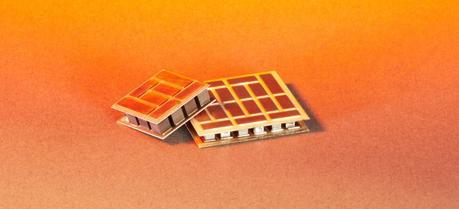

The individual components of thermoelectric modules are only a few millimeters in size. They are cut from specific alloys — such as half-Heusler compounds. (Credit: Fraunhofer IPM)

The individual components of thermoelectric modules are only a few millimeters in size. They are cut from specific alloys — such as half-Heusler compounds. (Credit: Fraunhofer IPM)

Half-Heusler thermoelectric compounds that convert waste heat into electricity have been manufactured for the first time in kilogram quantities (1 kg = 2.2 lbs) in Germany.

More than two-thirds of the energy from primary sources like oil and gas utilized worldwide today is lost through waste heat. A thermoelectric generator could potentially convert that heat into electrical energy. For example, if integrated in the exhaust system of an auto, such a module could use the waste heat for electrical power generation and take some of the load off the alternator.

“In view of the continually stricter environmental regulations of the EU, this can also be of interest to the automobile manufacturers,” according to Dr. Kilian Bartholomé from the Fraunhofer Institute for Physical Measurement Techniques (IPM) in Freiburg, Germany.

Even though the fundamental principles have been known for almost 200 years, most of the technology is still at an elementary stage. Efficient manufacturing processes and suitable thermoelectric compounds are still needed. IPM has succeeded in making a big jump in development. The researchers have shown that half-Heusler compounds—that are highly suitable materials for thermoelectric processes—can be produced significantly more efficiently and cost-effectively than has been previously possible.

“Half-Heusler compounds are highly suitable for thermoelectric applications. They fulfill—almost—all of the necessary criteria,” explains Project Director Dr. Benjamin Balke, an expert in materials development at University Mainz. “The alloys consist of a wide range of materials, nickel being one, and are much more environmentally friendly than previous materials, possess good thermoelectric properties, and withstand high temperatures.”

The efficiency of a thermoelectric compound depends on the so-called figure of merit, ZT. Industry requires thermoelectric compounds with ZT values greater than one. The partners in the thermoHEUSLER Project have now achieved a value of 1.2.

“That corresponds to the best published values for half-Heusler compounds thus far,” says Bartholomé. It is crucial for industrial applications to attain the efficiency values during mass production that were obtained in the lab. During the thermoHEUSLER Project, Vacuumschmelze and Isabellenhütte have successfully manufactured this very efficient half-Heusler material in kilogram quantities for the first time. The alloys synthesized by them result from a long tradition: the German mining engineer, chemist, and namesake of the compound, Friedrich Heusler, was head of Isabellenhütte Heusler GmbH at one time.

Thermoelectric modules are assembled from blocks a few millimeters each in size. These consist of two different types of thermoelectric materials, N-type and P-type. A critical aspect for the efficiency of the modules is the design of their electrical contacts. These need to withstand large temperature differences, yet at the same time keep the electrical resistance as small as possible. This is exactly what the scientists have accomplished in the thermoHEUSLER Project by using a specially developed soldering system.

Various international consortia have shown that thermoelectric modules can contribute to energy efficiency in automobiles. Prototypes have already created up to 600 watts of electrical power from the waste heat in the exhaust system of an auto. “There were almost 60 million motor vehicles registered in Germany at the beginning of the year. If all of these were equipped with small thermoelectric power plants in the exhaust systems, energy on the order of the amount produced annually by a nuclear power plant could theoretically be saved today,” according to Bartholomé. “That corresponds to a savings of several million tons of CO2.”