The Ultimate Guide To

Heating Pipework

Covering Every Type Of Heating Pipe

When you think home heating, it’s likely that radiators and heated towel rails immediately spring to mind. And whilst we might be pre-conditioned to do so, it’s easy to forget about the fundamental elements that can quite literally make our devices tick. Or hum. Or buzz. Etc. Etc.

Quite often though, these underlying features are absolutely integral to how your domestic heating operates, and different types or styles can lead your devices to perform more or less efficiently, with greater or lesser reliability.

In this blog, we’ve decided to focus on the many different types of heating pipework on the market, to highlight which sorts are best suited to particular components, provide installation tips as well as cost hints and more.

Basically, find everything you need to know about heating pipework in our Ultimate Guide To Heating Pipework.

What Is Heating Pipework?

Essentially, heating pipework or piping networks involve a system of pipes which are used for the transportation of liquids – mainly water. There are all sorts of initial design considerations to make regarding the installation of pipework, with adherence to building principles and regulations amongst them.

We promise to try our best not to bore you with overcomplicated jargon, but an Ultimate Guide needs to at least briefly highlight the guidelines outset in these regulations. As such, we can confirm that Approved Document B of the building regulations state that pipework “includes pipe fittings and accessories. The definition of ‘pipe’ excludes a flue pipe and a pipe used for ventilation purposes, other than a ventilating pipe for an above-ground drainage system.”

You could be forgiven for not realising the role, or even the presence of pipework amongst plenty of heating-related paraphernalia. All sorts of devices and components incorporate pipes, inclusive of gaskets, bolts, valves, supports, flanges, strainers, flexible and expansion joints, plus simple pipes.

These key fixtures have varied purposes – typically to read and control the fluid flow rate, temperature and pressure.

What Materials Are Used To Make Heating Pipework?

There are a few main materials used in the construction of heating pipework, each boasting their own unique properties, advantages and disadvantages.

Stainless steel and carbon fibre are the most popular pipework manufacturing materials on the whole. However, there are a whole host of other non-metallic, plastic and lined piping options available too, including concrete, copper, fiberglass and aluminium.

An overview of each type will follow later in this article, but as a basic starting point, any decision on material should take into account the array of conditions the pipework will encounter. In particular, the shifts in material strength in environments with enhanced temperatures. Given that fluid flow can cause erosion or corrosion in pipework over time, it is a sound idea to choose a material that will corrode slowly at a rate that is known.

How Is Heating Pipework Fitted?

Before we get into the ins and outs of various pipework materials, it’s worth looking at how piping is fitted in relation to contrasting types of central heating systems.

Essentially, three main arrangements are typically in place to connect the boiler to your home radiators or heated towel rails. These come in the form of a single pipe loop, feed and return pipes, and a micro bore.

In most cases, the heating pipework will be installed beneath the radiator. It can be fitted underneath the floorboards in rooms with suspended timber flooring, with risers used to connect the pipes to the radiators. It’s a good idea to support the pipework beneath the floorboards too, so the pipes themselves aren’t tasked with supporting excessive weight.

However, hardwood flooring is a lot more commonplace in modern properties, and this installation means isn’t appropriate for areas with solid floors. Usually, these types of pipework fittings will feature high level feed pipes connecting to adjacent or single domestic radiators. For spaces with suspended ceilings, the piping will typically be installed between the joists of the ceiling from overhead, but that might not be viable if each floor is a dwelling of its own.

Another option is to set the pipes to travel around the top of the wall slightly beneath the ceiling using fall pipes. In reality, it’s never a favourable alternative to run the floor pipes along the floor level, as issues are sure to surface where the piping needs to cross doorways. In such instances, the pipes would have to be wound around the door frame or buried underneath the floor, which might be a touch too invasive for your taste.

In the event that high level feed pipes require installation in an attic or loft space, the pipework will need to be insulated. You can insulate pipework in more ‘normal’ locations if you prefer too, and it will likely bolster your energy conservation levels in doing so, but it’s not generally necessary outside of attics.

And in instances where the circulating pipework is positioned higher than the radiators or other connected heating devices, the pips will have to feature bleed valves to release any air trapped within the system.

Pipework Installation Options

Single Pipe Loop

As the moniker suggests, single pipe loop systems feature a lone pipework loop which runs from and returns to the boiler. All radiators involved are positioned upon the pipe with each radiator connection leading to the same pipe. As heated water from the boiler travels along the pipe, convection occurs, leading the heated water to elevate into the radiator, sending cooler water back to the pipe.

One of the major drawbacks of this sort of pipe arrangement is that the first radiator will heat up to a greater extent than the second and third one and so forth. As such, the final radiator in the system will be significantly cooler as it will have transmitted the majority of its heat to the initial radiators on the pipe run.

Theoretically, an unlimited amount of domestic radiators can be installed on a single pipe loop. But, the more radiators that are fitted, the more apparent will be the cooling between the first and final radiators.

Single pipe loop systems are more regularly found in industrial settings in which the loop pipe could be immensely large, as opposed to residential buildings. Modern domestic pipework installations are highly unlikely to follow the single loop line, and instead focus on a more efficient pipe fitting arrangement.

Feed and Return Pipes

Feed and return pipe arrangements operate in a more efficient manner than single pipe loop systems. Within them, the boiler’s heated water is transferred to one side of each radiator (the feed pipe), whilst the opposite end of the radiators is connected to a separate common return pipe. As a result, the temperature of the water infiltrating each domestic radiator is practically the same, so a very similar heat output should be emitted from each heating device.

An automatic bypass valve, or pressure relief valve, connects the feed and return pipes, enabling the pump to transport boiler water should all the radiators be shut off at any one time.

On account of the flow restriction dictated by the radiators, the amount of radiators required is generally limited by the scope of the circulating pump. A standard pump for domestic feed and return pipework installations will typically offer an adequate supply for up to 12 radiators or heated towel rails.

The size of the piping can prove another limitation to the number of radiators fitted too. In most instances, the main pipes entering and exiting the boiler are significantly sized at over 22mm, with smaller pipework (15mm or less) tailing off to feed a few radiators or alternate heating components. Just how many residential radiators can be fed through these smaller pipes will be dependent on the length of the 15mm pipe runs. The longer the length of the pipe run, the less radiators will be needed. Heating professionals would tend to recommend no more than three radiators are run along a single 15mm pipe branch.

This more modernized setup, sometimes referred to as a two-pipe system, is far more likely to be found in contemporary homes, and is typically better suited to serve domestic needs in residential properties.

Micro Bore Piping

Micro bore piping arrangements make use of standard pipework for the feed from the boiler to manifolds, and from manifolds back to the boiler on the flip side, or the return to speak a touch more technically. Small pipework (typically 8mm) stems from each manifold, connecting to several radiators. The piping between each manifold and the radiators usually measures five metres or shorter.

It could be that special radiator installation techniques are utilised to ensure both the feed and return micro bore pipes are attached to the same end of each radiator. Contrastingly, the pipework could be fed into the opposite ends of the accompanying radiators.

Micro bore pipework systems are another type to include a pressure relief valve between the return pipes and boiler feed in order to offer protection to the boiler when all the radiators are switched off.

One of the most prominent advantages of a micro bore piping arrangement is that the smaller pipes don’t have the capacity to carry so much water, so less heat is wasted over each pipe run. Furthermore, micro bore pipes can be manipulated to shape quite easily during fitting, and they require less joints than other types.

In terms of disadvantages, the sizing of the pipe also works against it in some sense, as they can become blocked quite easily as a result of internal sediment. Also, the pump will have to combat increased resistance when transporting the water from the boiler, making the pump more susceptible to wear in turn.

Also, it’s worth considering an alternative to micro bore pipework if you live in an area with a hard water supply. Limescale can quickly build up in circulating pipework, and prove especially damaging to this type of pipe arrangement. If you do opt for micro bore pipework in such a place, a water softening device or suitable additive will be an essential attachment.

Original Pipework Materials

Would Mike Skinner and The Streets have shot to fame with this slightly rendered debut album title? Ok, so a first playback might not have been forthcoming, never mind a second, but scrutiny into heating pipework materials is certainly warranted.

There’s a plethora of different materials used in the manufacturing of plumbing and pipes, and as promised earlier, we’ve cast our eye over each sort to identify their unique properties, pros and cons.

Copper Pipes

Offering excellent flexibility and a more compact make-up than other galvanized steel counterparts, copper piping is amongst the very most popular types on the market. And whilst it can be a touch susceptible to corrosion, again it is usually less so than other galvanized steel pipes.

Copper tubes are lightweight with thin wall sections, and can be supplied in coiled or straight format to suit any type of plumbing network. As such, it is a suitable piping material for all kinds of arrangements, be they a single pipe loop system for commercial purposes or a two-pipe residential installation.

A copper pipework fitting can come to fruition via lead-free soldering or brazing, or with the assistance of couplings or compression fittings.

Keep in mind that for braze welding, an especially skilled installer would be required, very likely at a higher cost than a standard plumbing professional. Compression fittings offer a far simpler process, but could prove potentially obtrusive.

Decent insulation is of paramount importance when opting for copper heating pipework too. Once the radiators or alternate heating components have been supplied with the hot water they need to deliver an impressive heat output, the property must be capable of good heat retention, or copper will enhance the prospect of heat loss occurring.

Given that copper is a metallic material too, electrolytic corrosion must be a factored concern. Such a reaction typically takes place if galvanized steel fixtures or fittings make contact with copper or brass pipes. In turn, water flow emerging through copper piping cannot exceed three metres per second. Plus, the conductivity properties of the material dictate that grounding connections must be separated from electric wiring and pipework arrangements.

Galvanized Steel Or Iron Pipes

Pipework constructed from galvanized steel or iron can be accurately brandished as the ‘safety-first’ type of system, and it remains heavily utilised in the fire safety industry for the transportation of water now. Indeed, this sort of piping network has long been recognised as the classic, traditional go-to for water conveyance.

From inception, in being ‘galvanized’, the steel would be encapsulated in molten zinc following pre-treatment cleaning. This would provide a premium level of protection both internally and externally, one that isn’t achievable via the use of modern electroplating technologies which are commonly used to manufacture contemporary steel or iron pipes. This latter method does tend to deliver a prettier, more polished aesthetic however.

Declining in popularity certainly from a domestic perspective, traditional galvanized steel or iron pipework brings with it notable and fair concern with regards to internal and external corrosion when teamed with alternative materials. The presence of the likes of brass or copper radiator valves would therefore make it difficult for these kind of arrangements to prove viable in residential settings.

Galvanized steel and iron pipework is especially robust and of a significant weight, and is generally fitted via the screwing and threading of fittings together. The installation process for this particular type of piping is especially laborious and less straightforward than is the case with non-metallic pipe systems.

Concrete Pipes

At the height of durability, precast, rigid concrete pipework holds a strong claim as the most resilient, hardest wearing type available.

Concrete pipes bore excellent strength properties and are supremely robust, which makes them a viable candidate for installation in busy commercial environments in particular. They boast a proven track record with regards to dependability and structural integrity, only further enhanced in modern times through innovation in pipe design, mixing and manufacturing processes.

In addition, concrete pipes are amongst the most efficient and environmentally friendly styles on the market, given their typical lifespan, long-term maintenance costs and the fact that they can usually be locally sourced.

Most of the aforementioned properties and features, in particular the standout material strength, help to facilitate a hassle-free, reliable installation process. One that typically reduces the stress of the workload, as well as the liability, for the owner and/or fitting professional. Furthermore, with a proper specified and inspected installation, concrete pipework is the cheapest type to fit in comparison with other materials of piping arrangements.

Aluminium Pipes

Versatility is the key element that usually forms the base of the discussion in relation to aluminium pipework, in no small part due to the seamless design of the tubing both internally and externally.

Amongst the most aesthetically appealing styles of available piping systems, aluminium pipes generally boast a shiny, reflective finish that can actually accentuate home interior when not concealed, especially when utilised in conjunction with chrome radiators or heated towel rails, for instance.

But whilst incorporating impressive corrosion resistance properties, aluminium pipes can also be powder coated, polished or anodised to achieve the specific look the buyer is hoping to achieve.

There are contrasting grades of aluminium piping, and whether or not the difference between them is viewed as important will depend on the buyer and the type of installation that is occurring. In addition to the specific layout of the space the aluminium pipes are slated to be fit in.

To broadly define each grade, one sort is wholly suitable for forming, bending and swaging, harping back in a literal sense to the flexibility features that are so readily associated with aluminium tubing.

The alternative graded aluminium piping has a tougher profile, making them a prime proposition for threading, drilling and machine work, although both grades of aluminium pipes are ideal for welding.

Aluminium pipes are also supplied ready for use, which lends itself to a simplified, and often cheaper installation process. Outside of cutting and chamfering, no special requirements exist and no special tools are necessitated, so labour costs are typically low with regards to aluminium pipe system fittings.

Fibreglass Pipes

Renowned for an excellent resistance to corrosion, and often found to make applications boring similar properties operational, fibreglass pipework essentially consists of a polymer matrix that is reinforced with glass fibres.

Fibreglass pipes also boast a proven propensity to tolerate high pressures, which has seen their popularity soar in relation to certain commercial ventures. Specifically, the likes of fire water services have tended to favour fibreglass piping over traditional steel options in modern times.

There’s no need for extra lining or coating on account of the corrosion resistance of fibreglass pipework, which assists in enabling it to retain a lightweight profile. Fibreglass pipes are roughly around 15% as heavy as steel alternatives and about 10% the weight of concrete counterparts.

As a non-conductive material, fibreglass poses no threat to electric radiators, which wouldn’t require a hot water supply anyway. However, fibreglass pipe arrangements stand up to the most rigorous standards with regards to weight, stiffness, dimensional criteria and overall cost.

Indeed, fibreglass pipes incorporate remarkably low maintenance fees, given that they are extremely simple to maintain through a failure to rust, and the fact that they require very minimal environmental protection.

And installation pricing will typically be very reasonable as well, aided in no small part by the lightweight nature of the piping, which makes it easy to manoeuvre and fit into position safely and correctly.

Plastic Pipes

This style of pipework often gets a bad rap, and in some ways its understandable. The perception of plastic pipework typically defines it down as a cheaper option, and thus lesser quality version, in comparison with other materials.

And although that might be true to an extent, there are some instances where a plastic piping network can work a treat – particularly if cleverly concealed from view, then the aesthetic is one less significant factor to worry about.

This is one such reason that plastic pipe arrangements are popular accompaniments to underfloor heating, as well as the flexibility of the pipes which enables them to run up to 25 metres underground without any joint requirements.

Such immense flexibility makes them a relative doddle to install too, so you shouldn’t need to fork out excessive amounts for a successful fitting, nor to purchase the pipes initially, as you might imagine.

Plastic pipes are also less prone to freezing, and tested to a 10 bar pressure gauge for peace of mind regarding performance.

All things considered, they make for a more attractive proposition than they are perhaps given credit for, especially in the case of prospective residential underfloor heating system fittings. Further detail can be found in our BestHeating Best Buddies: Plastic Pipework blog.

Carbon Fibre Pipes

Sometimes referred to as graphite fibre, this material is surprisingly strong for one so lightweight. In fact, carbon fibre can pertain to feature strength properties around five times as robust as steel, and a profile that is twice as stiff.

The makeup of carbon fibre pipework incorporates slimline, strong crystalline carbon filaments which serve to enhance the strength of the material. Carbon fibre itself can be thinner than a single strand of hair, gaining strength when woven together to create a solid form.

In addition to immense strength and a lovely lightweight and streamlined shape, carbon fibre pipes provide excellent chemical resistance, and with low thermal expansion, are temperature tolerant to excessive heat.

Even if that last point might be fairly obvious of a type of heating piping, it is relevant in making carbon fibre pipework systems such a popular fixture within many commercial sectors. The likes of the automotive and aerospace industries, as well as the military, have long made use of carbon fibre piping within a range of heating network vocations.

It works out cheaper to install on a larger scale, especially considering how thin the material is, which is another factor in the carbon fibre piping arrangements usually being favoured commercially rather than domestically.

Stainless Steel Pipes

Last but not least under the microscope is stainless steel piping, which is amongst the most very popular types not least due to its outstanding resistance properties concerning corrosive elements.

Repelling oxidation and erosion, stainless steel pipes incorporate nickel and chromium within their makeup, also assisting with the high strength and ductility they possess, even at soaring temperatures.

They’re another versatile pipe arrangement option, with the capability to be heat treated meaning they can be quite easily welded into a variety of sizes and shapes to suit any layout or heating system they’d supply to.

Plus, reasonable installation costs, along with simple maintenance and a typically long service life endear stainless steel heating pipes to many from both a residential and commercial perspective. All these factors combined lead stainless steel pipework to be viewed as one of the very most sought after across industrial and domestic pursuits combined.

Heating Pipework Configurations

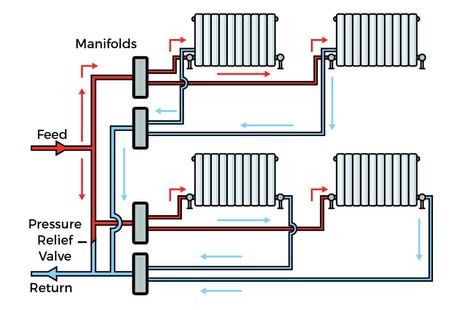

We touched on heating pipework installation options earlier in the piece, but such is the scope for a variety of different configurations to be used, we required some visual assistance too.

Single Pipe Loop Systems

The accompanying diagram displays a single pipe loop system which delivers a hot water supply to four separate radiators in this example. (Theoretically, single pipe loop networks can provide water for an unlimited amount of radiators or alternate heating devices.)

In this most simple of arrangements, water emerges from the boiler, travelling along the feed to supply the top two radiators as pictured. The water continues to journey along the same pipe to enable the bottom two radiators to heat up as well, though maybe not to the same extent as the first components on the pipe run (one of the biggest disadvantages to this sort of system).

That said, the discrepancy between the heat outputs of each radiator shouldn’t be excessive in a single pipe loop system as pictured in the diagram. The more radiators that are included on a single loop network, the larger the rate of cooling will be from the first rad to the last.

It is perhaps easiest to envisage this sort of heating pipework system in a commercial setting such as an office or a large retail store, where several radiators might be required to maintain a relatively low level of heat over a sizeable surface area generally.

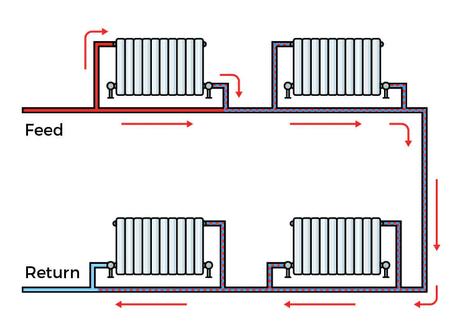

Feed and Return Pipe Systems

With regards to feed and return pipe systems, the visual representation quite literally paints a more obvious picture as to how this type of heating network operates more efficiently than a single loop arrangement.

As demonstrated, water from the boiler enters one side of each radiator via the feed pipe, with a separate return pipe connected at the opposite end of each component. This ensures that the water reaching all radiators is round about the same temperature, so they should all produce a similar heat output.

Both the feed and return pipes are connectable via a pressure relief valve or automatic bypass valve, which allows the pump to carry boiler water even if all home radiators have been turned off for a period.

Whilst the diagram shows four radiators, standard feed and return pipe system installations can accommodate up to 12 heating devices.

The size of the circulating pump and flow restriction specifications of radiators or heated towel rails could influence this total, however. As could the length of the piping. Following a general rule, the longer the pipe run length is, the less radiators will be required. It is recommended that a maximum of three radiators are situated on one 15mm pipe branch, though most main pipes which enter and exit the boiler are 22mm or longer.

This sort of two-pipe network is a more likely candidate for domestic vocations, in which it can provide a comfortable level of warmth continuously as needed.

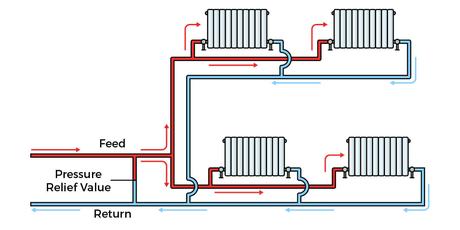

Micro Bore Pipe Systems (Two Pipes)

The other two-pipe arrangement we can explain easier with the benefit of a diagram is a micro bore pipe system. As shown in the image, this type of system connect feed pipework from the boiler to manifolds, and from manifolds back to the boiler on the return pipe.

Diminutive pipes branch out from the manifolds, usually measuring 8mm, to deliver a water supply to multiple radiators or alternative heating devices. The total length of the pipework connecting each manifold to the radiators is typically five metres or less.

In the example pictured, both the feed and return micro bore piping are attached to the opposite ends of the four radiators. But it should be noted that the application of specialist fitting techniques can see the pipework connect to the same end of the radiators, if that sort of setup is preferable.

A pressure relief valve again features to provide boiler protection at any time all the radiators within the system are turned off.

Get In Touch With BestHeating

By this point, you’ll hopefully be able to tell your single loop pipework systems from your feed and return arrangements, and have some sort of idea which pipe materials would be most favourable for any domestic or commercial installation you might be pondering.

If you would like any further help or advice regarding heating pipework though, or any other heating-related topics for that matter, please don’t hesitate to get in touch with the BestHeating team, who’ll be more than happy to help in any way we can.

You can do so by leaving your thoughts in the comments section below, or by contacting us via Facebook, Instagram or Twitter.

bestheatinguk

1,142 21,296

Turn your home heating into home decor with BestHeating.com. Tag us in your pics #mybestheating for a chance to be featured!