Being a mechanical engineer and a diehard fan of automotive technology, I always had a dream to see an automobile manufacturing plant so as to observe and learn all the latest cool Industrial stuff implied in next generation automobiles.

Luckily I got this once in a blue moon golden opportunity to explore Tata Motors state-of-the-art production plant facility which is located at Sanand, Gujarat. Before taking you for the deep dive into automotive stuff, let me first tell you some cool things about this production plant.

This production plant was built in a record time of 14 months, starting November 2008, the integrated facility comprises Tata motors’ own plant, spread over 725 acres, and an adjacent vendor park, spread over 375 acres, to house key component manufacturers for the Tata Nano.

In addition with the most advanced world-class manufacturing practices, the Tata Nano plant has been equipped with state-of-the-art equipment. This includes high tech robotics and high speed production lines.

Some Interesting facts:

- Every 58 seconds a Nano is rolled out from the Sanand Plant.

- Delivery of Tata Nano started from July 2009 and almost 2.75 lakh Nano cars have been produced till May 2015.

Sounds Interesting? Hmm?

I know all of my batch mates and friends would be feeling jealous of me after reading this… Right  ?

?

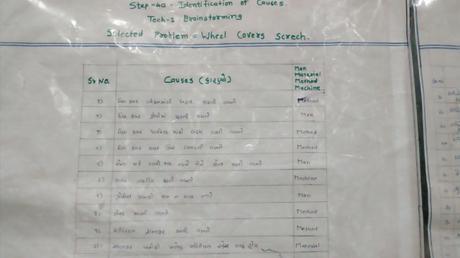

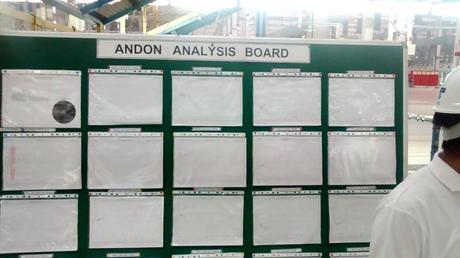

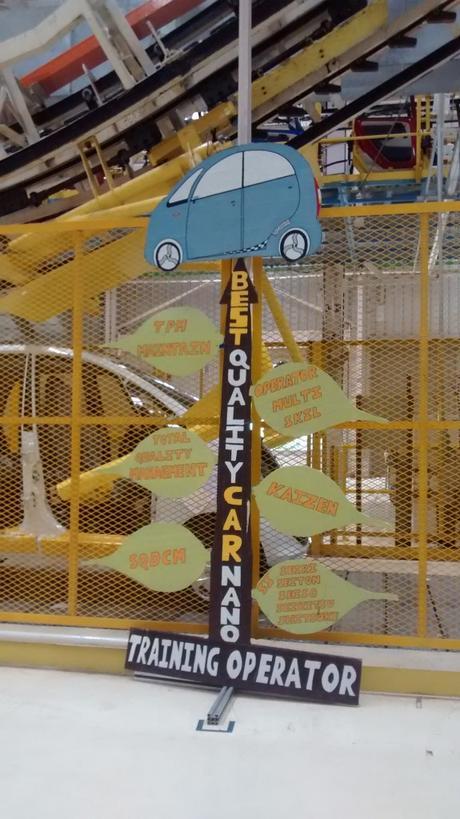

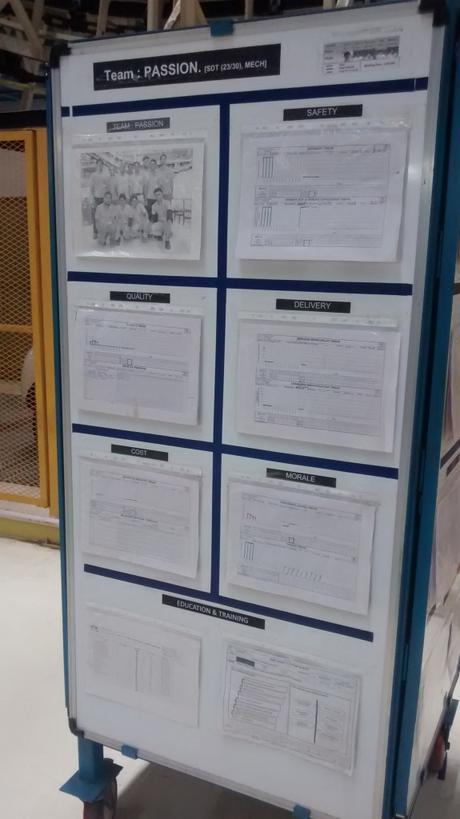

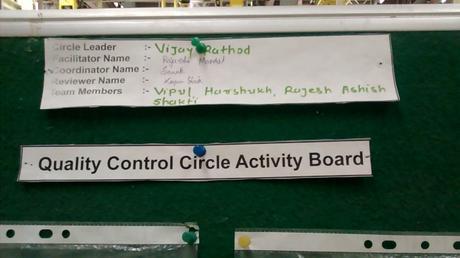

During my mechanical engineering course studies, I learned about a lot of Industrial safety & quality standards from our professors although we were also aware that these things are never followed by most of the Industries. But When I entered into the Tata Nano production plant I was really amazed to see that they had implemented each and every International industrial safety and quality measures on full scale. I saw Zero defect policy, Andon Charts, Quality Circle, Total Quality Management, TPM Maintain, Kaizen, SQDCM, Process Chart, Work Cards etc. everything which I have learned in all of engineering studies into practical use which I could have never imagined.

We were provided with a safety helmet before moving into the production facility and briefed with a set of standard safety procedures and guidelines to ensure our well being.

The plant tour started from the press shop where the skin panels of Tata Nano are made from the different blanks of different shapes and sizes received from vendors. The main equipment in the press shop is press line(Type: Komatsu), Which is fully automatic, thus ensuring right quality in the first attempt avoiding any human error.

The second shop was weld shop, The skin panels from the press shop are welded in a pre-defined sequencing process in order to make the body of Nano. Mainly spot welding operation is done in the weld shop with MIG welding.

The third shop we visited was paint shop but no one is allowed to enter into it because of operational limitations. So we saw it from the outside only and It was really huge. Here colour coating is applied on the car body as per the requirement.

The fourth shop is Power Train/Engine shop, where main power train assembly is carried out inside a dust-free AC environment on conveyer line and can produce an engine in less than a minute.

The fifth shop is TCF (Trim Chassis Fitment), here the final assembly of car is done including each and every accessories such as seats, steering wheel, window glass, wheels, buffers etc.

Assembly Area Video

The completely built car comes out of the TCF, and is ready for testing and inspection.

Almost all of the production process was automated and performed by customized robotic arms which were much similar to the size of “auto bots optimus prime” (If you know what I mean aka Transformers) to provide greater accuracy and precision in each and every single production process. Although photography is strictly prohibited inside the plant premises, we were able to capture some pictures of the plant at specific location due to special permission from Tata Team.

During our tour we were guided by Head of Engineering Change Dept., He explained about all of the technical terminologies which are made into use by the ground force and technical operators team very well. He also told us that assembly line chain system can carry about 380 cars (approx) at a time and I was really amazed to see that.

To be honest, I used to think that Tata Nano is not that safe to drive in heavy traffic roads and rough terrains but when I saw all of the efforts & engineering practices being followed by Tata Motors, I realized that I was holding onto a silly myth from such a long time.

After we covered all the indoor workshops (i.e. operation areas) of the plant, we were taken to see the on ground testing of Tata Nano’s to observe what level of quality & safety checks are performed over them before sending them to their lucky owners in order to ensure their safety.

On Ground Testing Videos:

Tata Nano Vibration Testing Video:

Tata Nano Water Run Testing:

We saw Torture track tests in which the Tata Nano’s were driven over the worst kind of roads which can be seen anywhere in India and I can guarantee you that all of them were easily able to withstand that. Trust me!!!

After that we saw the water run test which is performed to make sure all the Tata Nano’s can pass the Delhi roads during rainy days!!! Just Kidding  This test was one of the tolerability tests.

This test was one of the tolerability tests.

Both of these on ground testings were a lot of fun for all of #TheChosenOnes but Being a mechanical engineer I was aware that these on ground tests are the best way to ensure the proper quality of cars before putting them into the hands of their owners.

Luckily, we also got a chance to drive these amazingly cool cars in the testing track which was of infinity shape. Basically these kinds of track are used to confirm the maneuvering and steering control efficiency of automotive vehicles.

Last but not the least, The Tata Motors Plant, Sanand is a Zero-discharge plant (ETP i.e. Effluent Treatment Plant). They treat the effluents from all the shops as per pollution control board norms, Through ETP the effluent is reused for horticulture and gardening purposes. Sounds Amazing Hmm?

I guess I should forward my resume to them for the profile of Production engineer at this plant. Who knows? Maybe I get Lucky

I’m really thankful to Tata Motors team for inviting me to join this awesome journey to their magical auto world with a bunch of topmost bogging stars. I wish to join them again soon in near future.

Do let us know If you have any queries regarding anything related to this post or any suggestions.

Disclaimer: I’m writing this post on behalf of Tata Motors as a part of #TheChosenOnes campaign. All content & opinions are mine.