Scientists at Stanford have developed a heat-resistant thermal emitter capable of remaining stable under temperatures as high as 2,500 °F (1,400 °C). Thermal emitters are used in thermophotovoltaic systems to convert heat into infrared light, which can than be absorbed by solar cells to make electricity. For a thermal emitter its ability to operate at high temperatures is a crucial factor because efficiency increases with operating temperature.

Thermophotovoltaic (TPV) energy conversion is a direct conversion process from heat differentials to electricity via photons. A basic thermophotovoltaic system consists of a thermal emitter and a photovoltaic diode cell. The temperature of the thermal emitter varies between different systems from about 900 °C to about 1300 °C, although in principle TPV devices can extract energy from any emitter with temperature elevated above that of the photovoltaic device (forming an optical heat engine). The emitter can be a piece of solid material or a specially engineered structure.

A conventional solar cell is effectively a TPV device in which the Sun functions as the emitter. The problem is, silicon semiconductors only respond to infrared light. Higher-energy light waves, including most of the visible light spectrum, are wasted as heat, while lower-energy waves simply pass through the solar panel.

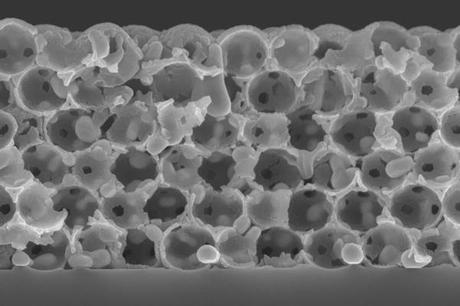

The cross-section micrograph of the thermal emitter shows the ceramic-coated tungsten retained structural integrity after being subjected to 2,500 F (1,400 C) for one hour. (Credit: Kevin Arpin). Click to enlarge.

“In theory, conventional single-junction solar cells can only achieve an efficiency level of about 34 percent, but in practice they don’t achieve that,” said study co-author Paul Braun, a professor of materials science at Illinois. “That’s because they throw away the majority of the Sun’s energy.” For example, this August JA Solar Holdings Co., one of the world’s largest solar cell producers, announced that its multi-crystalline silicon (“multi-Si”) solar cells have reached an industry-leading conversion efficiency of 18.3%.

Thermophotovoltaic devices are designed to overcome that limitation. Instead of sending sunlight directly to the solar cell, thermophotovoltaic systems have an intermediate component that consists of two parts: an absorber that heats up when exposed to sunlight, and an emitter that converts the heat to infrared light, which is then beamed to the solar cell.

“Essentially, we tailor the light to shorter wavelengths that are ideal for driving a solar cell,” said Shanhui Fan, a professor of electrical engineering at Stanford University. “That raises the theoretical efficiency of the cell to 80 percent, which is quite remarkable.”

So far, thermophotovoltaic systems have only achieved an efficiency level of about 8 percent, Braun noted. The poor performance is largely due to problems with the intermediate component, which is typically made of tungsten – an abundant material also used in conventional light bulbs.

“Our thermal emitters have a complex, three-dimensional nanostructure that has to withstand temperatures above 1,800 °F [1000 °C] to be practical,” Braun explained. “In fact, the hotter the better.”

In previous experiments, however, the 3-D structure of the emitter was destroyed at temperatures of around 1,800 °F (1,000 °C). To address the problem, Braun and his Illinois colleagues coated tungsten emitters in a nanolayer of a ceramic material called hafnium dioxide.

The results were dramatic. When subjected to temperatures of 1,800 °F (1000 °C), the ceramic-coated emitters retained their structural integrity for more than 12 hours. When heated to 2,500 °F (1,400 °C), the samples remained thermally stable for at least an hour.

The ceramic-coated emitters were sent to Fan and his colleagues at Stanford, who confirmed that devices were still capable of producing infrared light waves that are ideal for running solar cells.

“These results are unprecedented,” said former Illinois graduate student Kevin Arpin, the lead author of the study. “We demonstrated for the first time that ceramics could help advance thermophotovoltaics as well other areas of research, including energy harvesting from waste heat, high-temperature catalysis and electrochemical energy storage.”

Braun and Fan plan to test other ceramic-type materials and determine if the experimental thermal emitters can deliver infrared light to a working solar cell.

Original article by Mark Shwartz.

Arpin KA, Losego MD, Cloud AN, Ning H, Mallek J, Sergeant NP, Zhu L, Yu Z, Kalanyan B, Parsons GN, Girolami GS, Abelson JR, Fan S, & Braun PV (2013). Three-dimensional self-assembled photonic crystals with high temperature stability for thermal emission modification. Nature communications, 4 PMID: 24129680