Owners of class 8 vehicles are waiting longer and longer to replace their trucks – and the reason why is pretty basic: the high cost of buying a new vehicle. The good news, however, is that maintaining your current equipment longer is a viable money-saving strategy over the long-term. But to do so effectively, you need to know the trends and understand the most cost-effective methods.

Owners of class 8 vehicles are waiting longer and longer to replace their trucks – and the reason why is pretty basic: the high cost of buying a new vehicle. The good news, however, is that maintaining your current equipment longer is a viable money-saving strategy over the long-term. But to do so effectively, you need to know the trends and understand the most cost-effective methods.

First things first: equipment is lasting longer than it did 30 years ago. That fact saves money for fleets and owner-operators every day. John Blodgett, Vice President of Sales and Marketing for industry research firm MacKay & Co., recently told Truckinginfo.com that the life cycle of class 8 parts has been steadily improving since the 1980s.

Blodgett notes that engine teardowns usually happened at 276,000 miles in 1982, but today that typically kicks in around 771,000 miles. Transmissions are now being replaced at 585,900 miles, whereas 30+ years ago that was occurring at 182,000 miles. Truckinginfo says, “This trend is true for other components like alternators, brake shoes, air compressors, and clutches.”

Better component longevity is great. But how do you save on parts once the inevitable happens and you’re faced with replacing something?

As is often the case, timing is crucial. On average, trucks between seven and nine years old are the ones that start to need replacement parts more often. Since the average age of fleet-owned class 8 vehicles has been hovering at the 10-year mark (9.74 years in 2014 ) – and with utilization pushing 90%+ in most sectors – maintenance managers need to keep an eye on that older inventory.

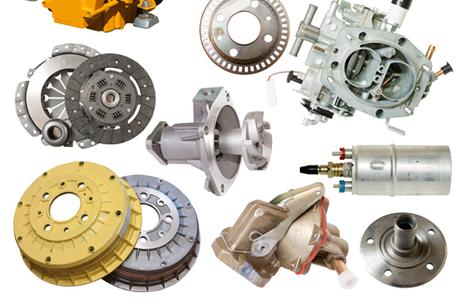

Where are replacement parts needed most?

Earlier this year, MacKay & Co. president Stu MacKay presented his annual Heavy Duty Aftermarket Dialogue to the Heavy Duty Manufacturers Association and noted that:

- 37% of replacement parts are needed in the power generation items

- 19% for undercarriage

- 15% for power transmissions

- 12% for cab and chassis

- 8% for electrical systems and components

These are the systems to watch – and the parts to source – before problems arise, bringing higher costs for urgent repairs.

Pedro Ferro, Senior Vice President and President of the aftermarket & trailer division for Meritor, told Fleetowner.com, “Suppliers that are true ‘aftermarket survivors’ must flourish in this tough market by staying true to their convictions of high parts availability and responsive delivery.”

“Owners with an average vehicle age of nine to 10 years are focused on quality replacement parts availability and overall lifecycle costs. They also want a supply distribution channel with appropriate product support, counsel and expertise.”

One potential avenue: reputable vehicle suppliers who also have their own parts supply arm. For instance, Ryder’s focus on reliable vehicles led to the creation of Ryder Fleet Products, which not only supplies thousands of discounted parts for the vehicles it maintains, but also sells those same high-quality parts directly to consumers.

Trends to watch

Recently, Pedro Ferro outlined the major trends impacting the aftermarket parts business for Fleetowner.com. The emphasis is on value brands and cost-efficient sourcing:

- Private brands: OEMs and big large distributors are manufacturing their own parts brand to speed up repairs, drive service business to increase availability and choice.

- Online sourcing: Fleets are increasingly using the Internet for buying parts, and for comparison-shopping. It’s getting bigger every year.

- Value brands and All-makes: There’s nothing like genuine OEM parts. But value brands or all-makes cost less, have proven performance specs, and they get the job done. Call them “good-enough” parts.

- The remanufactured option: Here again, remanufactured components can offer significant savings, if the specs and documentation are there. Disassembly, cleaning, inspection and testing need to be part of the equation. Ferro told Fleetowner that quality ‘reman’ parts can deliver performance and component life at considerable savings.

The need for replacement and aftermarket parts grows as vehicles age. And the wish list is long: air conditioning and heating components, belts and tensioners, brakes, cargo restraints, cooling system, drivetrain, electrical, engine and fuel system, exhaust system, filters, hubodometers and gauges, lift gate parts, mirrors and mounting, mud flaps and brackets, steering and suspension, and so on.

The trick to great aftermarket parts is knowing how (and where) to get what you need … at your price.