Lantec is running a test to prove reliability of 4D Weld Watcher system. According to the manufacturer, partially ionized metal vapour is created during laser welding, cutting or soldering. This escapes from the weld pool and emits a broadband light, the so-called process light. The WeldWatcher measures this process light using a photo-electric sensor. By doing so, typical features, such as the beam flux density, spectral components, time or progress are analyzed and used for quality control.

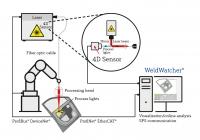

Lantec is running a test to prove reliability of 4D Weld Watcher system. According to the manufacturer, partially ionized metal vapour is created during laser welding, cutting or soldering. This escapes from the weld pool and emits a broadband light, the so-called process light. The WeldWatcher measures this process light using a photo-electric sensor. By doing so, typical features, such as the beam flux density, spectral components, time or progress are analyzed and used for quality control.The evaluation of the current measurement signals is performed by comparison with the stored reference signals using the envelope or threshold method. The Weld Watcher sensors are integrated into the laser with an adapter.

As part of the automatic evaluation of the process signal in the serial production, the result is shown with distinguishing colored marks in one or more welding group images. The graphical visualization shows the operator the test for the welding seam that is notified as being faulty.

Results from the test are shown, as well as the tolerance in which the process must run.