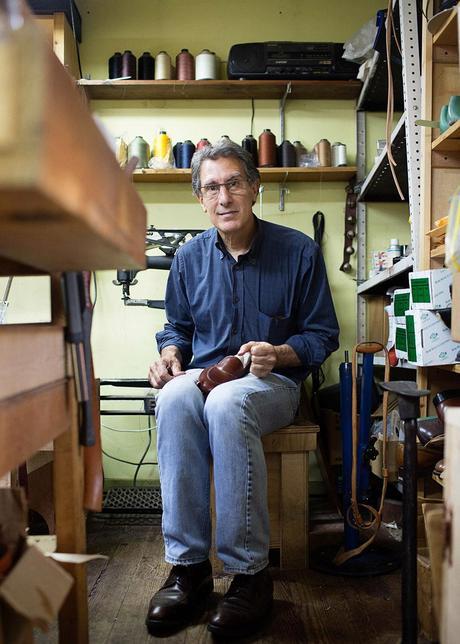

From my first step inside Perry Ercolino’s atelier, which sits two blocks west of Main Street in Doylestown, Pennsylvania, the dedication to craftsmanship was evident. The smell of leather was intoxicating and so was the display of museum-worthy, bespoke shoes and their lasts. It was porn for any handmaker. Hidden behind the main worktable was Perry, one of the best, maybe the best, shoe maker around. His tale is uncomplicated and non-convoluted. His father was a shoemaker and he followed suit, no qualms or reservations about it. Today, his business is in the vanguard of a still-living-and-breathing, old-world trade. With each pair of shoes, he brings fresh verve to established styles and marries traditional tailoring with dandy designs. Opening prices are high, but men and women who pay top dollar for the most refined clothing shouldn’t fail at the final hurdle – shoes. For these customers, Perry is offering them a way to get out of the monochromatic maze of Cole Haan and Coach.

My history is simple. I grew up in the business. My father was a shoemaker here in Doylestown during the depression and his shop was a half a block away from mine. When he retired in the late 1970s, I took over the business and I’ve been here ever since.

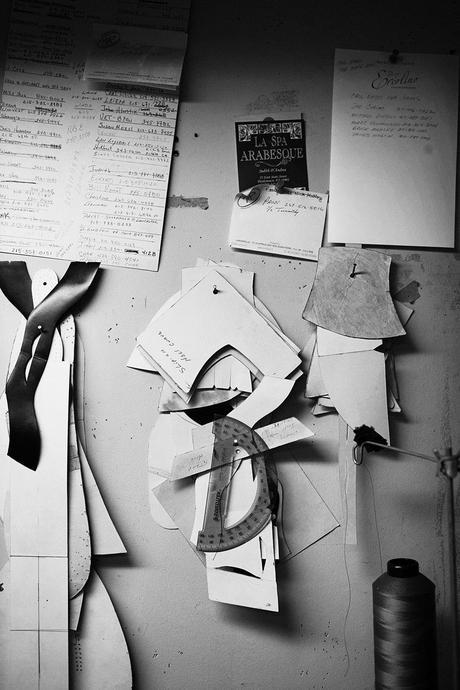

The shoemaking process begins by tracing and measuring the customer’s right and left foot. We then take that tracing and overlay it with a 2-dimensional pattern of what the bottom of the shoe last should look like. For those unfamiliar, a last is a 3-dimensional model of the foot; like a dress form but for shoemakers. Once this is finished, we send it to a lastmaker in the U.K., who creates a carved, wooden mold. Once he send it back, I begin the process of making the pattern for the shoes by drawing the style line directly on to the last. After, I use those style lines to create the pattern pieces, including the lining (a shoe as two separate layers: one for the top of the shoe and one for the inside lining).

The leather pieces are cut and sewn together to make the “uppers,” or top layer, of the shoes. The uppers are then humidify and stretched over a wooden form so that they can take shape and mold to the wood before final assembly. After, we take special pieces of leather for the back as well as for the toe area and insert them between the top and lining with a special wheat paste. This helps form the heel and toe areas as well as keeps them rigid for the life of the shoes.

The final phase is to attach a wooden, shank piece to the bottom for support under the heel. At the same time, pieces of cork are added, which provide cushion under the ball of the foot. The leather outsole covers all of that and is sewn onto a strip of leather (welt) at the bottom edge. Once the outsole is permanently attached, it is shaped to the contours of the shoe’s bottom. The heel pieces are then attached and the shoes are polished and fitted for a pair of wood shoe trees that replicate the shape of the shoe lasts that the shoe was built on.

The whole process from start to finish takes approximately 65 hours (actual work time).

I source all my leathers overseas. I use French, English, Italian and German calf as well as some English suede. I use mostly French because it’s more durable. Italian leather is a softer, but that’s because they remove the “bottom crust,” which takes away some of the fiber structure and compromises durability.

In garment sewing, there are various fit points on the human figure: shoulder, waist, hip, etc. In shoemaking, we have the same thing, but our fit points are the inside ball joint, the outside ball joint, the fifth metatarsal head and the long heel joint.

President Obama. I didn’t meet him, but I was given his measurements/size to make a pair of shoes – oxfords.

I’m sure I’ve had aspirations to do something else. Host The Tonight Show…