Scientists continuously

work to synthesize highly efficient materials that may one day constitute the building blocks of organic photovoltaic devices. Improving flexibility while reducing weight may just cut it, but how?Light weight plus flexible properties make it possible to produce solar cells at low cost. It also makes it easy to manufacture them using printing processes. This article explains what scientists are currently doing to improve the properties of solar cell materials.

The article from Karlsruhe Institute of Technology explains:

POPUP, the new BMBF-funded research project, aims at developing more efficient materials and new architectures for organic photovoltaic devices. An interdisciplinary team headed by Dr. Alexander Colsmann of the KIT Light Technology Institute (LTI) works on improving the basic understanding and developing new architectures for semitransparent and non-transparent solar cells and modules.

Ten leading universities, research institutions, and companies in various areas are involved in the project “Development of New Materials and Device Structures for Competitive Mass Production Methods and Applications of Organic Photovoltaics” (POPUP). The project is coordinated by the pharmaceutical and chemical company of Merck. The total budget of the three year project is EUR 16 million. The Federal Ministry of Education and Research (BMBF) funds EUR 8.2 million, the remainder is borne by the companies involved in the project. For its contribution to the research project, KIT is granted funding in the amount of EUR 1 million.

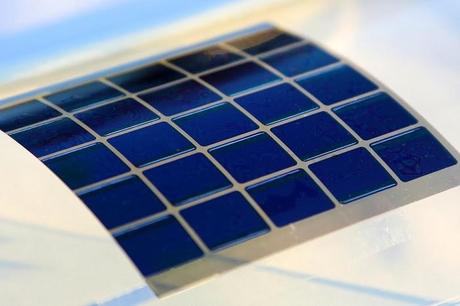

POPUP is to leverage organic photovoltaics. For this purpose, the consortium intends to develop more efficient and more stable materials for low-cost, industrially applicable printing and coating methods as well as new architectures for flexible and rigid, semitransparent and non-transparent solar modules. The tasks of KIT in this project comprise developing in-depth understanding and studying new component architectures for semi-transparent and non-transparent solar cells and modules in close collaboration with the industry partners.

Depending on the application, solar cells are manufactured on flexible plastic foils or rigid glass carriers. In the area of organic photovoltaics, KIT scientists work on two objectives, namely, full printability of solar cells and replacing indium tin oxide (ITO) as the electrode material. Instead, the scientists use conductive and transparent foils for flexible carriers. For glass carriers, they study the deposition of transparent electrodes from metallic microstructures and conductive buffer layers. In addition, the KIT team studies highly efficient semi-transparent solar cells in mini-modules made of organic semiconductors. Hence, KIT research concentrates on one of the key technologies of organic photovoltaics.

In the medium and long term, the industry partners plan to manufacture organic solar modules by competitive mass production methods. Later on, the solar modules are planned to be integrated into vehicles for electricity supply to onboard electronics, in buildings and glass facades, for energy supply of free-standing buildings and devices, emergency systems, transport and navigation aids. The novel technologies will also be used for off-grid electricity supply in the leisure activity sector or for charging mobile consumer devices. The results obtained by the KIT researchers will have direct impact on various applications.

Credits for this article:

Karlsruhe Institute of Technology (KIT) is one of Europe’s leading energy research establishments. Research, education, and innovation at KIT foster the energy turnaround and reorganization of the energy system in Germany.

Story + Image