Undies are one of the easiest garments to sew (don’t ask me to call them panties, because I won’t). Streamlining construction, I combine the front and the back pieces at the crotch, so the only seams to sew are the side seams. Easy to make, yes, but I need more hands and fingers to tell you the number of times I’ve made a pair, but couldn’t fit them over my hips. That’s until I learned about minimum stretch.

Working as an assistant in the technical design department, knits category, a big chunk of my time was spent flat measuring. Laying a garment flat on a table, I measured front body length, back body length, armhole depth, sweep, etc. One of the measurements I took was minimum stretch, and it was probably the most important spec I recorded. In a woven, closures such as zippers, buttons and plackets ensure that a customer can get in and out of a garment, but in a knit, you have to make sure that the garment can stretch enough so a customer can put his or her head, hips, hand or foot through the opening (that’s assuming it doesn’t have a closure). An example is a long-sleeve knit tee – one of the minimum stretch specs (there might be several in one garment) would be at the sleeve opening, and it would make sure a customer’s hand can get through. If the garment doesn’t meet spec, the pattern must be adjusted (or garments resewn) before it goes to production. No way, no how would any retailer allow a style to hit stores that a customer couldn’t wear. This is what I was missing in my undie makings.

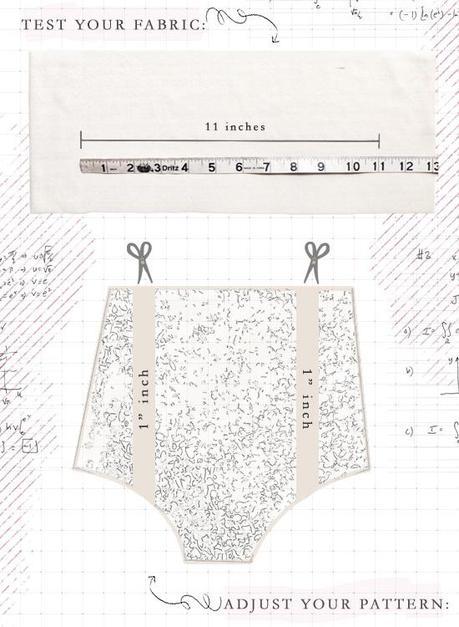

In an undie, the minimum stretch spec would be at the waist, and two factors affect it – fabric and elastic. If you want to wear that pair of undies you’re making, you have to make sure both the fabric and the elastic stretch to the largest part of your bottom half – your hips. How do you find this out? Let’s take my current, WIP pair as an example. The widest part of my hips measures 33 1/2″ (yes, I’m straight as a board from waist to hip), so I had to make sure that the waist opening, which measured 11″ flat, stretched to at least 17″ (which is the flat measurement of my hips: 33 1/2″ divided by 2). So, I cut a rectangular piece of my intended fabric and marked 11″ in the center (don’t mark at the edge – it’s not an accurate place to take this kind of measurement). I then stretched it to see if it would extend to 17.” It didn’t, so I increased to 12,” and it still didn’t meet the requirement. Thirteen ended up being the magic number, which meant I had to slash straight from waist to leg opening and open the pattern 2″ on front and back as shown below (you’re pattern will be on the half, but the diagram shows a whole pattern for clarity). Once I made sure the fabric suited my pattern, I used the same method to test my elastic.

Because every fabric and elastic stretches differently, you have to test with every pair you make. Have you heard a lingerie maker express how important fabric is to fit? Well, it’s true!

I hope this gives struggling lingerie makers out there some help. I know I was frustrated when I couldn’t figure out what was going wrong and threw a ton of undies in the trash. So sad to see lace in such a place!