But Cause of Its Failure Remains Unknown

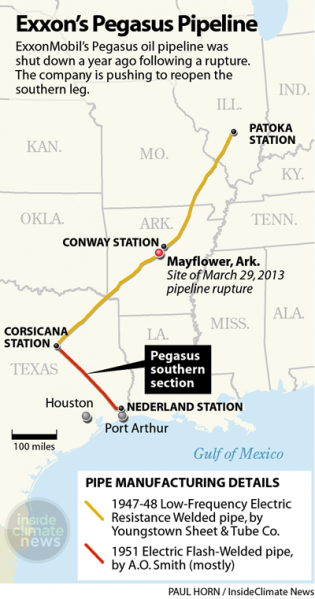

Now it’s official: ExxonMobil plans to fully reopen its idled Pegasus oil pipeline, including the 1940s-era segment that ruptured and dumped sticky tar-like Canadian dilbit into an Arkansas neighborhood. The Monday news ends the uncertainty over the pipeline’s fate that has hung over people along the Pegasus route since the spill one year ago—though why it happened remains unknown.

Exxon’s intentions are laid out in a one-page summary of how it plans to fix and verify the safety of the 650-mile northern section of the Pegasus, which includes the part that failed. The company intends to spend well into 2015 examining possible problems, completing repairs and running more robust tests on the pipeline, according to Exxon’s fact sheet.

The oil company’s detailed plan for those fixes, called a remedial work plan, was submitted to the Pipeline and Hazardous Materials Safety Administration (PHMSA) over the weekend, and a spokesman for the agency said it was under review. A separate restart plan would be filed once the work plan is completed next year. It’s unclear if either one of those plans will be made public.

So far, many key documents in the Pegasus case have been withheld from the public. Outside pressure from lawmakers forced disclosure of some of those, while others are kept secret or must be requested via the Freedom of Information Act—a long process at PHMSA. Much of the public and residents along the pipeline route in Illinois, Missouri, Arkansas and Texas remain unaware of what’s unfolding

Meanwhile, Exxon’s restart plan for the 210-mile southern leg of the pipeline, which runs in Texas from Corsicana to Nederland, won approval Monday from the Pipeline and Hazardous Materials Safety Administration. That segment is made from 1951 pipe that may have vulnerabilities similar to the pipe that split apart in Mayflower, Ark. Exxon must still submit a remedial work plan for that part of the Pegasus by April 7, but it hasn’t said when shipments will resume on the southern section.

That’s what is new in the Pegasus saga.

Here’s what is not new: The cause of the spill has not been fully explained.

Exxon’s new fact sheet summarizes the results of its year-long investigation into the Pegasus rupture, which the company said is now complete.

Last year, a metallurgy report concluded that the substandard fusing method used to make the Pegasus pipe left behind micro-cracks and other defects that formed hook cracks. Those hook cracks grew until the pipe fractured along its lengthwise seam, creating a 22-foot-long fissure. The report did not determine what caused the cracks to grow and destroy the pipe after more than 65 years.

Exxon now says its investigation found a secondary cause for the accident—”atypical” and “extreme” chemical properties in the pipe’s seam area. Those unusual properties include excess sulfur, manganese and carbon, Karen Tyrone, vice president of Exxon’s U.S. pipeline operations, said in aninterview with an Arkansas television station.

“We confirmed that the factors that resulted in the failure of the pipe in Mayflower, Ark., are one, an original manufacturing defect that was created when the pipe was manufactured, combined with extreme metallurgical properties,” Tyrone said in the interview.

She said the chemical characteristics made the pipe less able to flex, or more brittle, under stress. “We have not seen anything like this, and industry has not seen anything like this,” Tyrone said. In its new fact sheet, Exxon said the combination has not been detected elsewhere on the Pegasus or on any Exxon pipelines with similar characteristics.

But Exxon’s statements have puzzled several experts who said there’s nothing new here. Two of them noted that it’s well-known in the industry that the type and vintage of pipe used in the Pegasus has both crack defects and brittle—or as Exxon says “extreme”—characteristics around the seams.

Those characteristics were discussed in an InsideClimate News story last August. In the story, Patrick Pizzo, a professor emeritus in materials engineering at San Jose State University called it a “double whammy” to have a crack or flaw in the pipeline, and then to have that crack embedded in the brittle material around the pipe seams.

Pizzo and a pipeline failure expert pointed to the possible role of the pipe’s brittle seam area in the rupture, just based on industry literature and the descriptions provided in the original metallurgical report. Because Exxon has said there were no abnormal events prior to the rupture, both experts believe a third, still-unknown element activated and exacerbated the decades-old problems over time—perhaps large swings in pressure inside the pipe, excess hydrogen from the product or the corrosion prevention system, or something else.

Exxon’s explanations to date do not address the question of how the pipe’s inherent conditions progressed to failure.

John Tynan, director of public affairs for Central Arkansas Water (CAW), finds that curious.

“It does surprise me that Exxon has been doing tests on the ruptured pipe in Mayflower for a year and we still don’t know why the pipe ruptured,” said Tynan, who has been involved in the Pegasus case because the pipeline runs through an important CAW watershed.

“They’ve identified some additional contributing factors … but the hook cracks and manufacturing defects, as well as the atypical pipe properties, have all been in that line for 65 years,” he said. “It’s still unclear as to why this section of pipe ruptured last year.”